Anti-loosening thread pair and anti-loosening thread parts that can inhibit interface slippage

A technology of threaded parts and threaded pairs, applied in the field of mechanical connection, can solve the problems of fracture of threaded connection structural parts, slippage of threaded connection interface, and reduction of connecting force, etc., so as to improve the tightness, restrain the interface slippage, and moderate the tightening torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

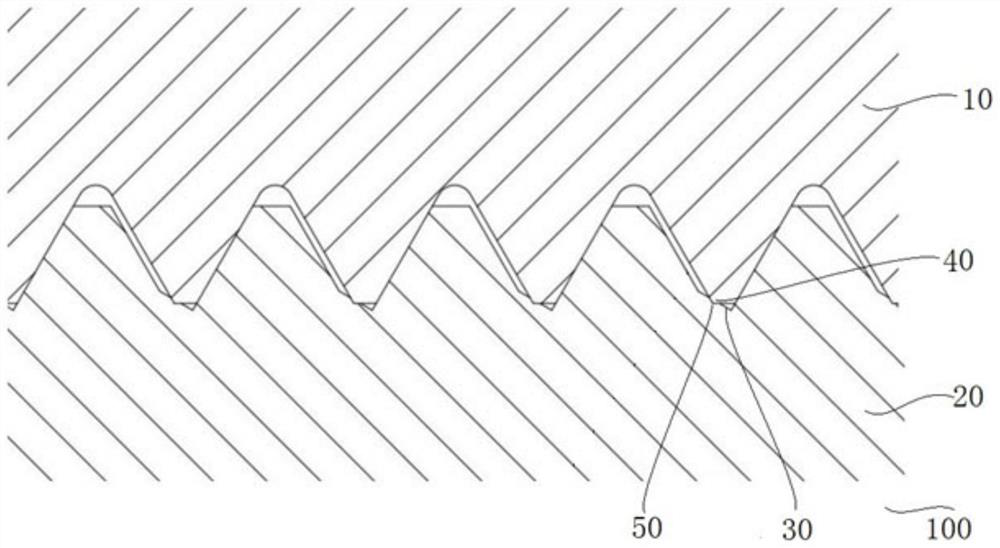

[0060] like figure 1 As shown, the anti-loosening thread pair 100 capable of inhibiting interface slippage is mainly composed of a first threaded member 10 and a second threaded member 20 . The first threaded member 10 may be machined with an inner hole, and the inner wall surface of the inner hole may be machined with first thread teeth extending along a helical line. The second threaded member 20 can be roughly processed into a rod shape, the outer wall surface of the second threaded member 20 can be processed with second thread teeth extending along the helical line, and at least a part between two adjacent second thread teeth can be processed with The transition surface 30, and the second thread can correspond to the first thread. In Embodiment 1, the first screw member 10 is screwed to the left relative to the second screw member 20 to form a force-bearing fitting area.

[0061] The transition surface 30 between two adjacent second thread teeth can be processed into an ...

Embodiment 2

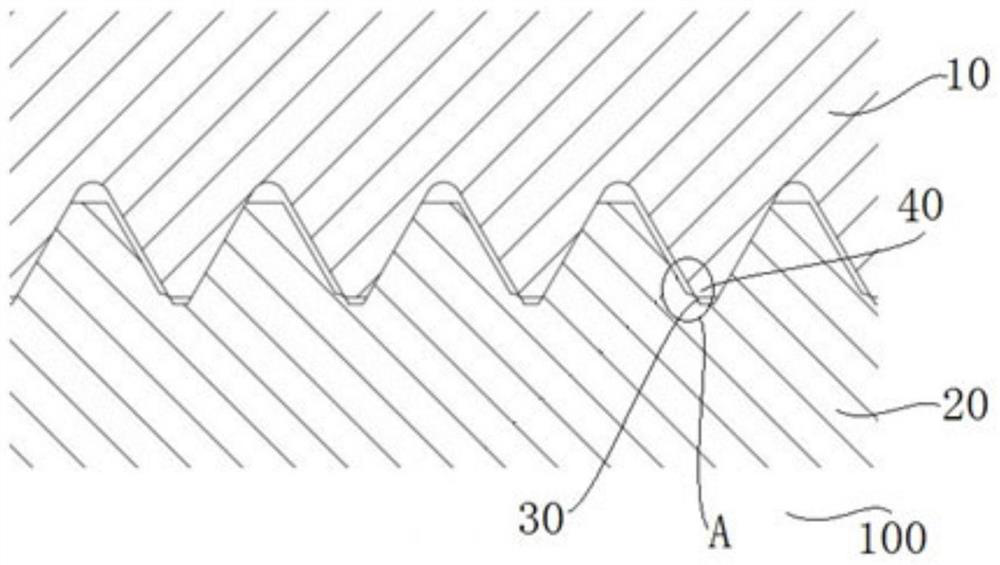

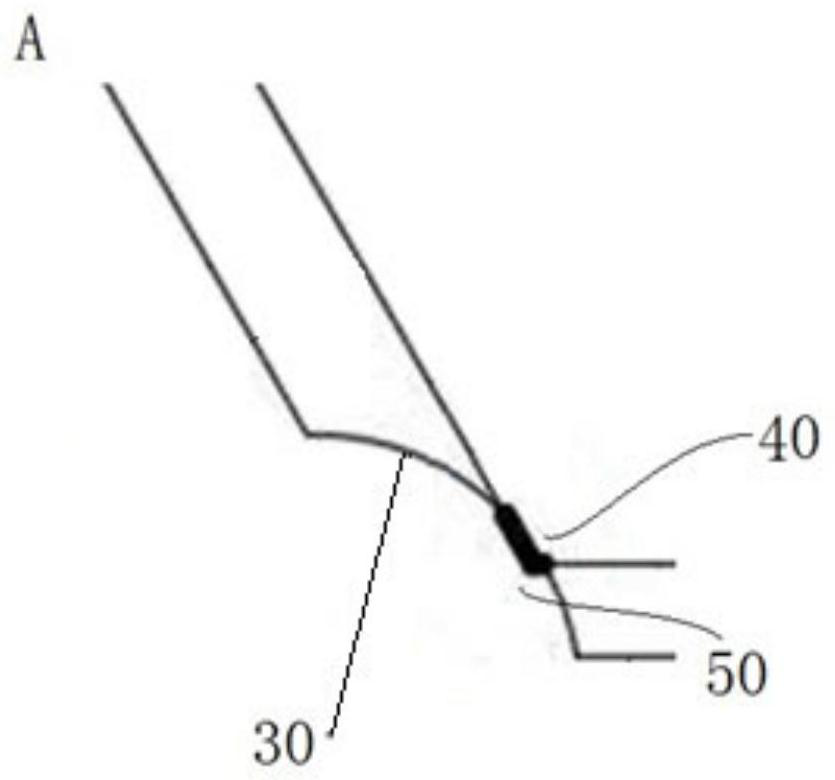

[0063] like figure 2 and image 3 As shown, the main structure of the anti-loosening thread pair 100 that can restrain the interface slip in the second embodiment is basically the same as the above-mentioned embodiment. In the second embodiment, the first screw 10 is relative to the second screw 20 Tighten to the left to create a load bearing fit area. The transition surface 30 between two adjacent second thread teeth can be processed into a curved surface, and a limited portion, that is, a groove 50 , can be processed on the transition surface 30 .

[0064] During the tightening process of the anti-loosening thread pair 100 , the tooth crest 40 can squeeze the transition surface 30 , and can also achieve a nested fit with the groove 50 while squeezing the transition surface 30 , so as to suppress the bearing force of the anti-loosening thread pair 100 . The purpose of the radial dislocation of the mating area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com