Maintenance-free air filter assembly

An air filter assembly, maintenance-free technology, applied in the direction of fuel air filter, combustion air/combustion-air treatment, engine components, etc., can solve the uneven technical level of maintenance personnel, increase the cost of vehicle use, main filter Some problems such as large dust, to achieve the effect of increasing the amount of pollution, reducing energy consumption, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

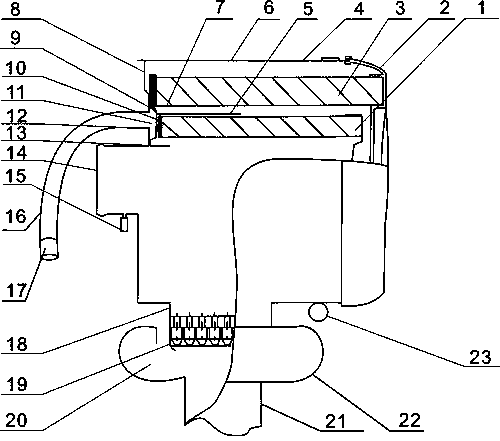

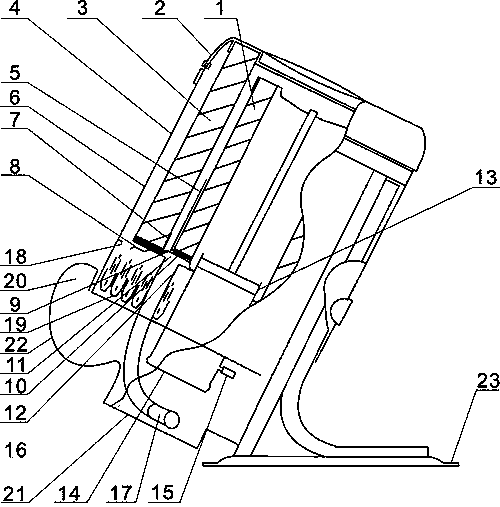

[0009] specific implementation plan

[0010] A maintenance-free air filter assembly, including: housing 4, pre-filter element 3, main filter element 1, pressure relief cavity 5, diversion cavity 7, bottom cover 8, auxiliary bottom cover 10, air passage 11, vacuum alarm device 15, high-pressure pipe 16, bracket 23, housing 4 is fixed on bracket 23, housing 4 is composed of pre-filter cover 2, side wall 6 and bottom cover 8, housing 4 is provided with main gas port 18, the outside of main gas port 18 Install primary filter 20, primary filter 20 is made of coarse filter 19, dust bag 21 and dust accumulator 22, primary filter 20 is installed in the bottom of housing 4, primary filter 19 can be gas centrifugal type primary filter or Wound-type coarse filter, the pre-filter element 3 is provided with a pre-filter cover 2, the pre-filter cover 2 is visible, the pre-filter element 3 is covered with a diversion cavity 7, and the diversion cavity 7 is designed on the middle ring of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com