Brake nipple for horizontal well conveying tractor perforating tool

A tractor and horizontal well technology, which is applied in the field of brake short joints, can solve the problems such as cannot be changed, cannot prevent accidents, cannot change the size of resistance, etc., and achieves the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below with reference to the accompanying drawings.

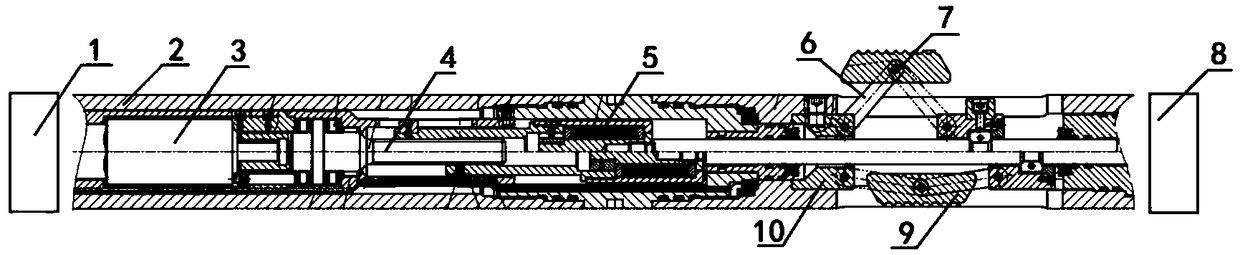

[0010] refer to figure 1 , The brake upper joint of the present invention is connected with the upper centralizer through threads. The brake control mechanism 2 is screwed between the brake upper joint 1 and the brake lower joint 8 . The brake pawl 9 of the brake control mechanism is located in the middle of one end of the two support arms 6 and is connected and fixed with a steel pin 7. There is a spring 5, and the push rod is connected with the motor assembly 3. The motor components adopt common motor components.

[0011] When the brake claw 9 is stretched, the motor assembly 3 drives the push rod 4 to move laterally, and the compression spring 5 pushes the push block 10 to move, thereby driving the brake claw to stretch upwards. Size, the maximum friction force is not less than 400kg, to realize the control of the movement state of the tractor perforating tool i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com