Construction device of cast-in-place concrete pipe pile and construction method of formed pile

A technology for concrete pipe piles and construction devices, which is applied in the directions of earth-moving drilling, drilling equipment and methods, drilling pipes, etc., can solve the problems of increasing construction costs and increasing the amount of concrete poured into piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

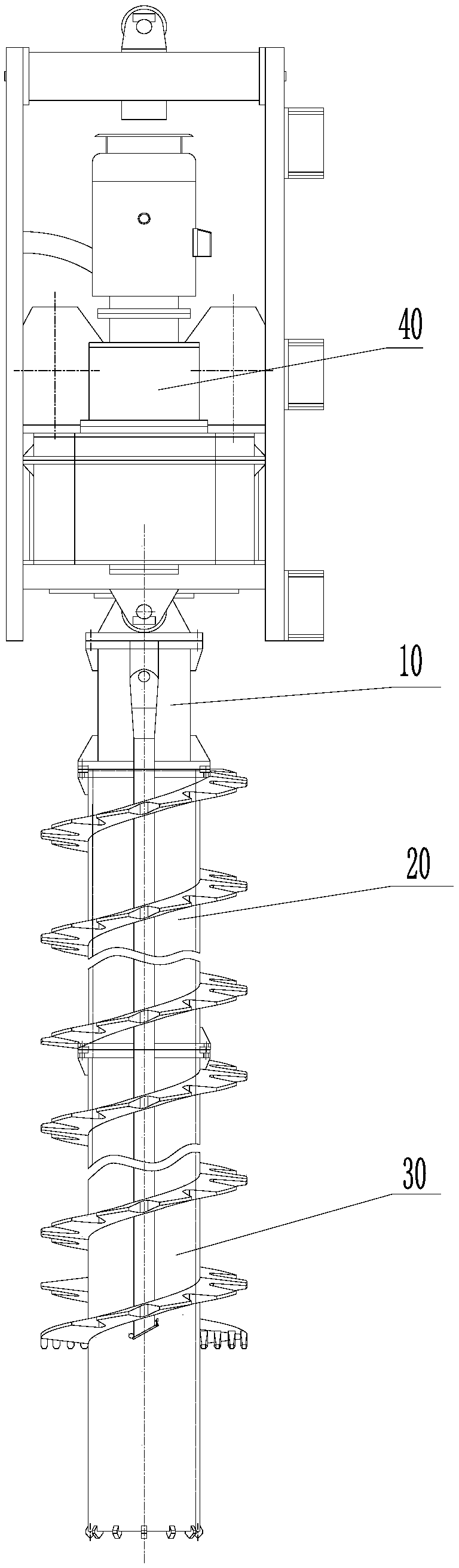

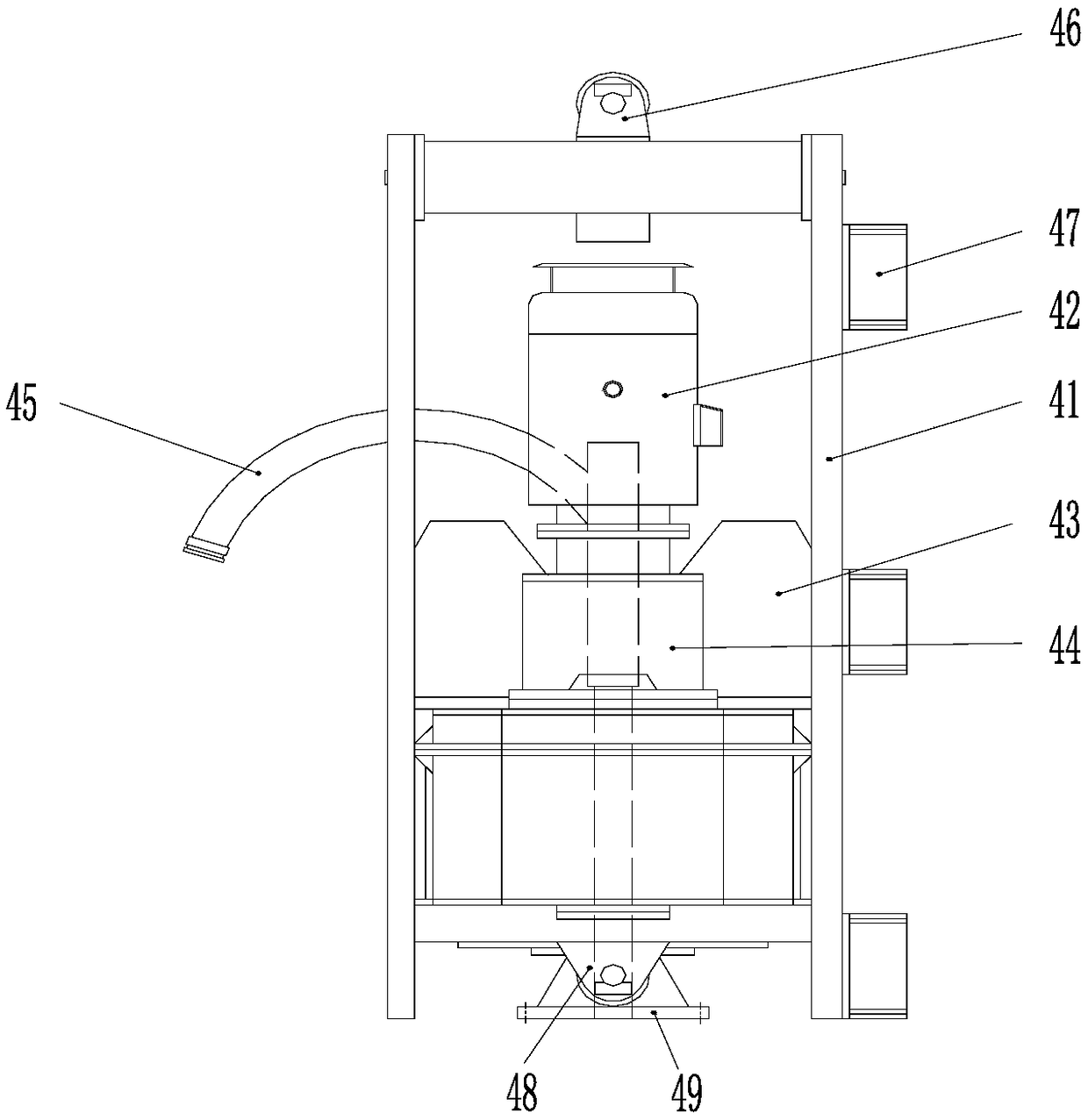

[0047] Such as Figure 1-Figure 11 As shown, the cast-in-place concrete pipe pile construction device is composed of a power head device 40 , a drilling tool reducing device 10 , several standard section drilling tools 20 and a bottom section drilling tool 30 .

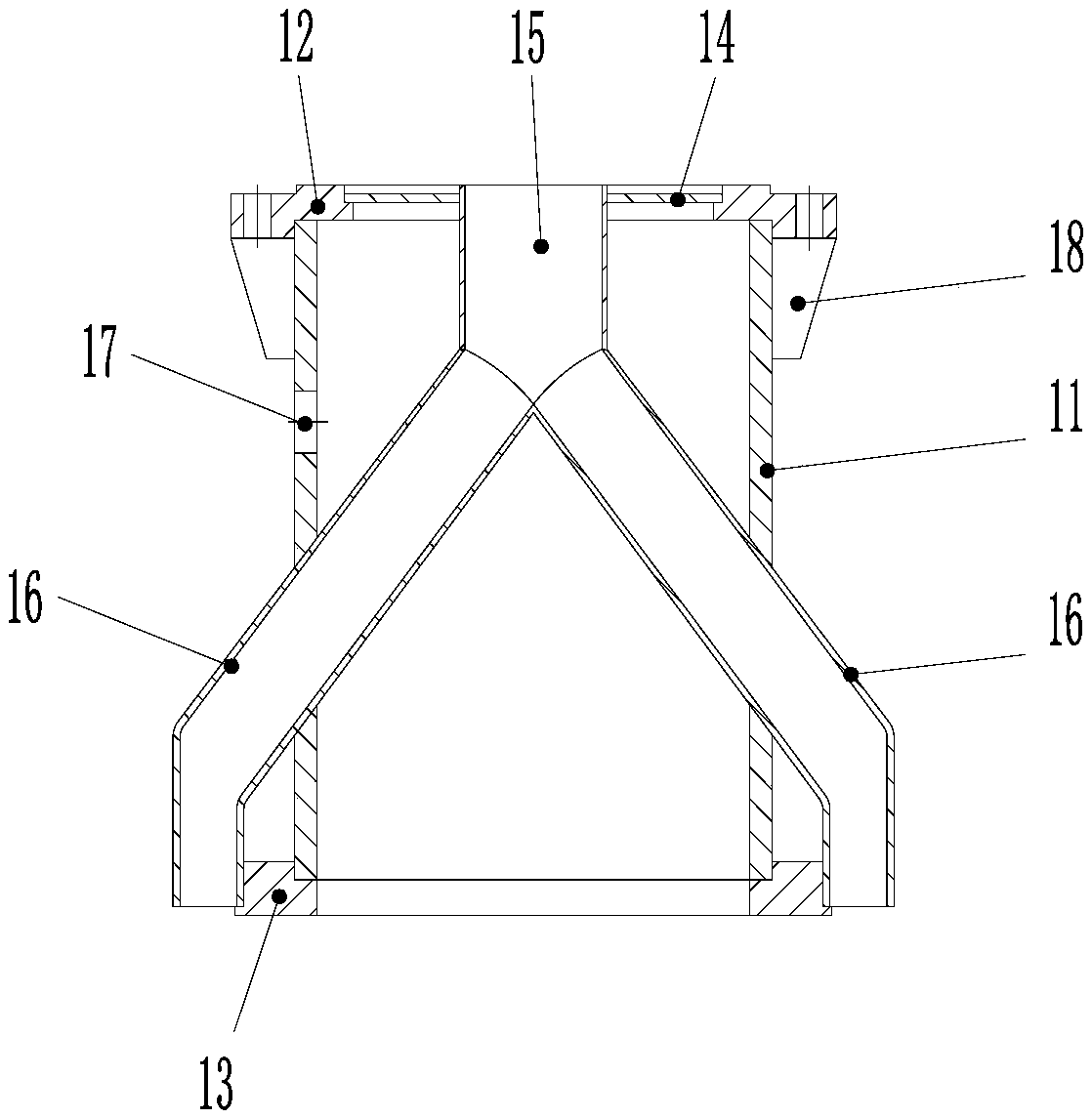

[0048] The drilling tool reducing device 10 is: composed of an annular outer pipe 11 , an upper flange 12 , a lower flange 13 , a blocking plate 14 , a main conveying pipe 15 , two auxiliary conveying pipes 16 and ribs 18 . The two ends of the annular outer pipe 11 are respectively provided with an upper flange 12 and a lower flange 13. The blocking plate 14 is installed on the upper flange 12. One end of the main delivery pipe 15 in the outer pipe 11 is connected with the blocking plate 14, and the other end is connected with the two One end of two auxiliary delivery pipes 16 is connected to form a herringbone structure and communicates internally, and the other end of the two auxiliary delivery pipes 16 protrudes fr...

Embodiment 2

[0059] Embodiment 2 A kind of construction method of cast-in-place concrete pipe single pile pile

[0060] Such as Figure 12 and Figure 13 As shown, adopt the cast-in-place concrete pipe pile construction device of embodiment 1 to complete the cast-in-situ concrete squeezed soil pipe pile, the method is as follows:

[0061] 1. If Figure 12 In (a), level the site, assemble the cast-in-place concrete pipe pile construction device and supporting construction equipment, place the pile hole position line, align the pile driver drilling tool with the pile position, and adopt a long auger drilled pile frame 60 with a large torque. The power head device 40 is installed on the frame 60, and the power head device 40 is used in conjunction with the concrete delivery pump. The drilling tool reducing device 10, several standard section drilling tools 20 and the bottom section drilling tool 30 are installed in sequence under the power head device 40.

[0062] 2. If Figure 12In (b), ...

Embodiment 3

[0065] Example 3 A construction method of cast-in-situ concrete pipe pile occlusal pile

[0066] Using the cast-in-place concrete pipe pile construction device of Embodiment 1, the difference is that the spiral extruding blade I23 on the outer wall of the core pipe I22 of the standard section drilling tool 20 is replaced by a spiral blade 37, and the core pipe II32 of the bottom section drilling tool 30 The screw extruding soil blade II36 on the outer wall of the screw rod part is replaced by a screw blade 37.

[0067] Such as Figure 12 and Figure 14 As shown, to complete the cast-in-place concrete pipe pile occlusal pile, the method is as follows:

[0068] 1, with the step 1 of embodiment 2;

[0069] 2, with the step 2 of embodiment 2;

[0070] 3, with the step 3 of embodiment 2, finish first cast-in-place plain concrete pipe 53 pile constructions;

[0071] 4. Move the cast-in-place concrete pipe pile construction device and supporting construction equipment to move th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com