Thermosetting type clothes printing screen printing ink, and preparation method thereof

A screen printing ink and heat-setting technology, which is applied in ink, dyeing, textiles and papermaking, etc. It can solve the problems of printing thickness not fast, unsafe and environmentally friendly, slow drying speed, etc., to achieve stable product quality and low cost of use , the effect of high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0025] 1) Add plasticizer into the mixing tank, add PVC paste resin while stirring, rotate at 500-700 rpm, time: 5-10 minutes;

[0026] 2) Continue to stir and add stabilizer at a speed of 700-1000 rpm for 5-10 minutes.

[0027] 3) After step 2), add fillers and toner pigments in 3 times, each addition must be dispersed evenly before adding, speed: 200-300 rpm, time: 10-15 minutes, temperature control at 38 ±1°C;

[0028] 4) After stirring and dispersing evenly, grind 2 to 3 times with a three-roller machine, and control the temperature at 34±1°C during ink grinding to obtain a thermosetting silk screen printing ink for garment printing.

Embodiment 3-4

[0030] 1) Add plasticizer into the mixing tank, add PVC paste resin while stirring, rotate at 500-700 rpm, time: 5-10 minutes;

[0031] 2) Continue to stir and add stabilizer at a speed of 700-1000 rpm for 5-10 minutes.

[0032] 3) After step 2), add the filler in 2 times. Each addition must be dispersed evenly before adding. Rotation speed: 200-300 rpm, time: 10-15 minutes, temperature control at 39±1°C;

[0033] 4) After stirring and dispersing evenly, grind 2 to 3 times with a three-roller machine, and control the temperature at 33±1°C during ink grinding to obtain a thermosetting silk screen printing ink for garment printing.

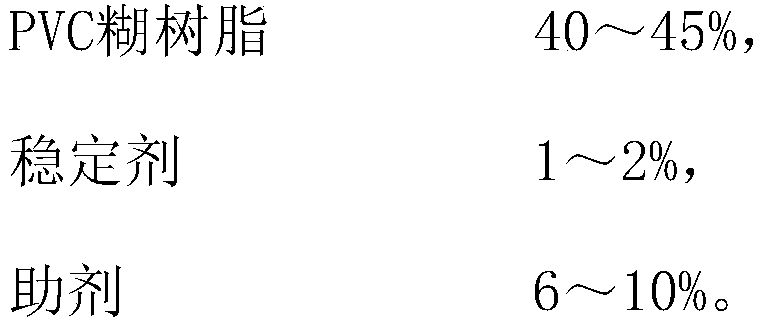

[0034] Table 1: each group distribution ratio in embodiment 1~4:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com