Conductive epoxy resin for modified carbon fiber composite laminated board

A technology of conductive epoxy resin and fiber composite material, applied in the field of conductive epoxy resin material and preparation, can solve the problems of structural mechanical properties decline, fiber breakage, etc., and achieve the effect of improving electrical conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution and preparation process of the present invention will be described in detail below in conjunction with specific examples.

[0032] Table 1 prepares the main raw material of conductive epoxy resin

[0033]

[0034] Preparation and testing instruments used in the experiment of preparing conductive epoxy resin in table 2

[0035]

[0036] Its raw material ratio of modified conductive epoxy resin comprises by mass percentage:

[0037]

[0038]

[0039] Preferred raw material formula is by mass percent:

[0040]

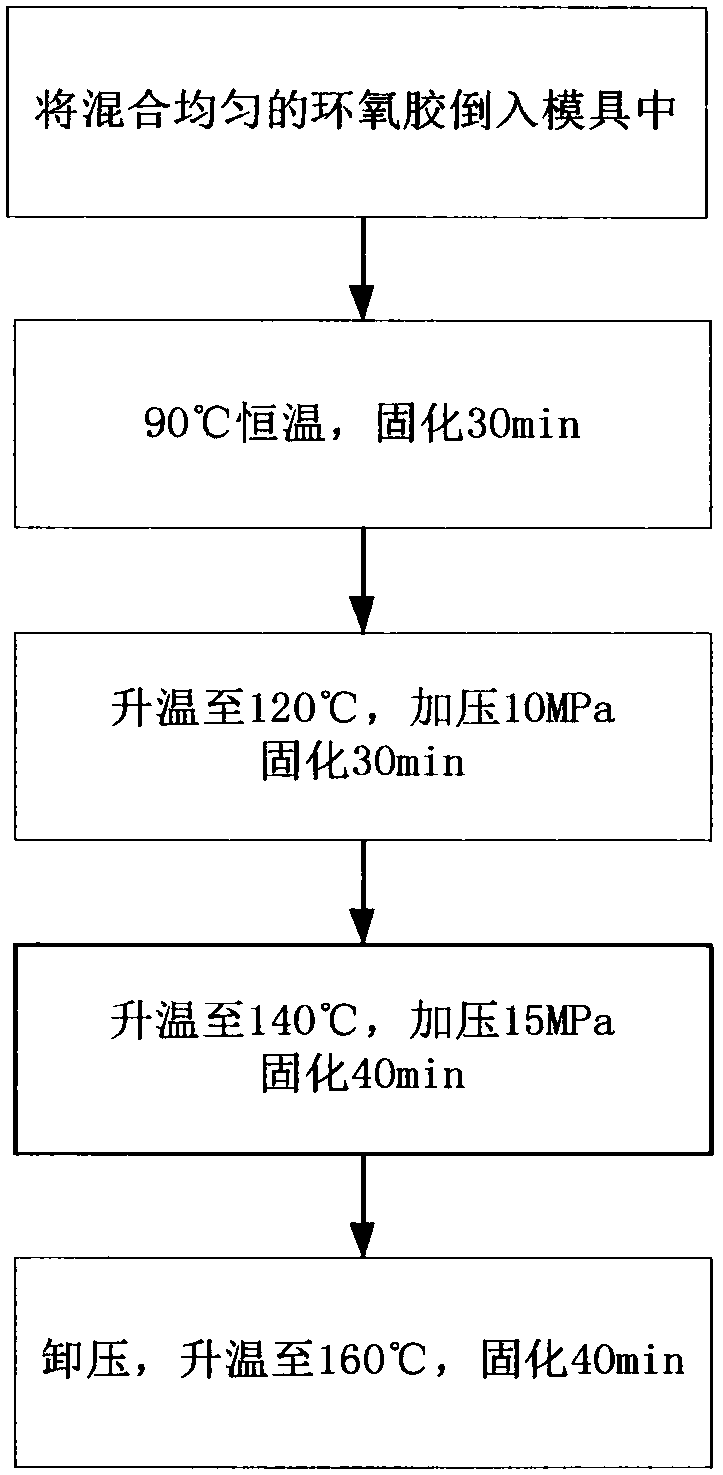

[0041] making process

[0042] a. Carbon nanotube treatment

[0043] Take a certain amount of carbon nanotubes and dry them at 70-90°C; accurately weigh the carbon nanotubes after drying to the required gram weight, and add ethylene glycol ether to dissolve them; Disperse for 1.5-3 hours. It is preferably dried at 80°C, ultrasonic frequency is 80Hz, and ultrasonic time is 2h.

[0044] b. Preparation of epoxy resin

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com