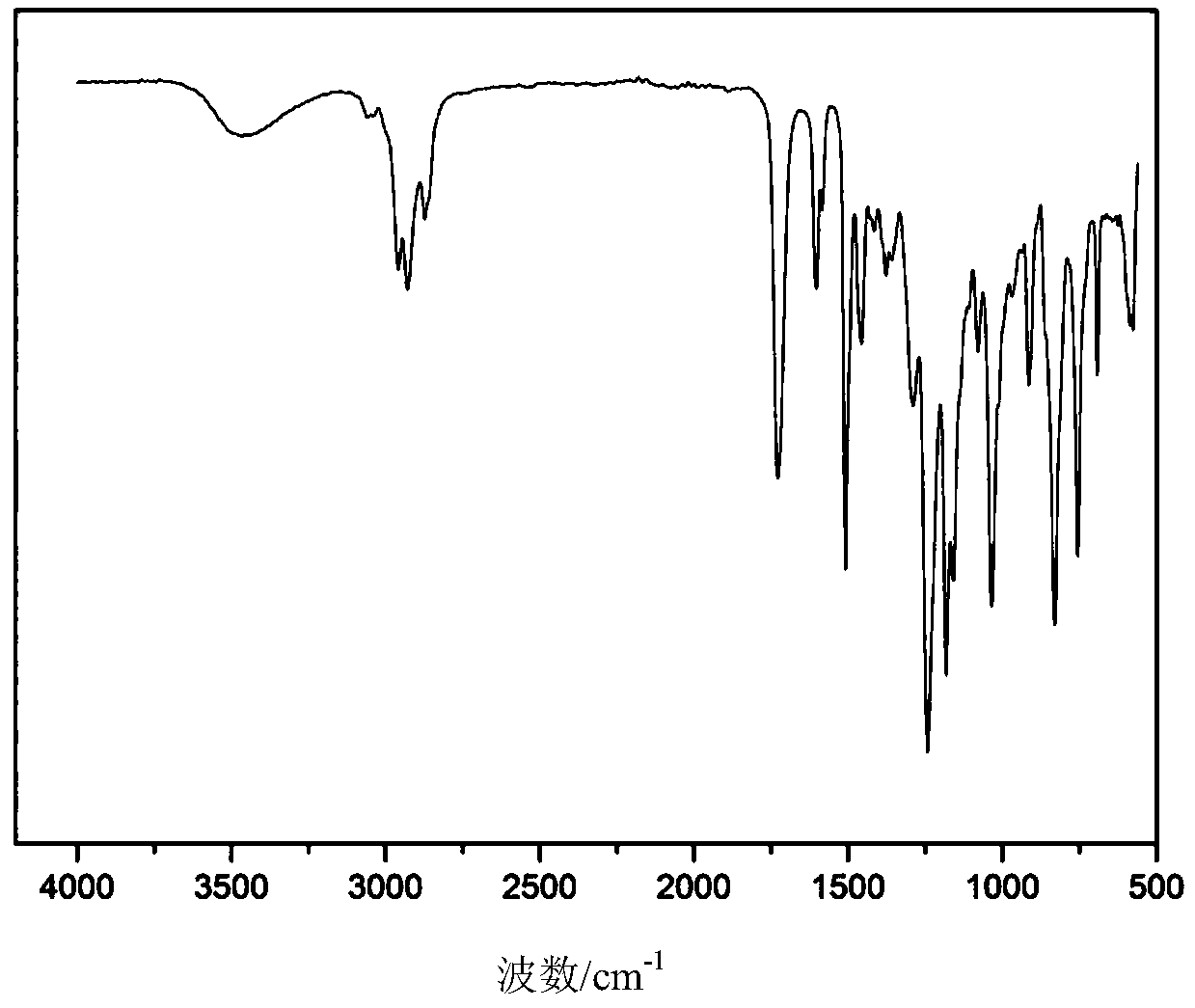

Bio-based flexible epoxy resin and preparation method thereof

A flexible epoxy resin and bio-based technology, applied in the field of material chemistry, can solve the problems of heavy odor and high product price, and achieve the effect of reducing glass transition temperature and improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

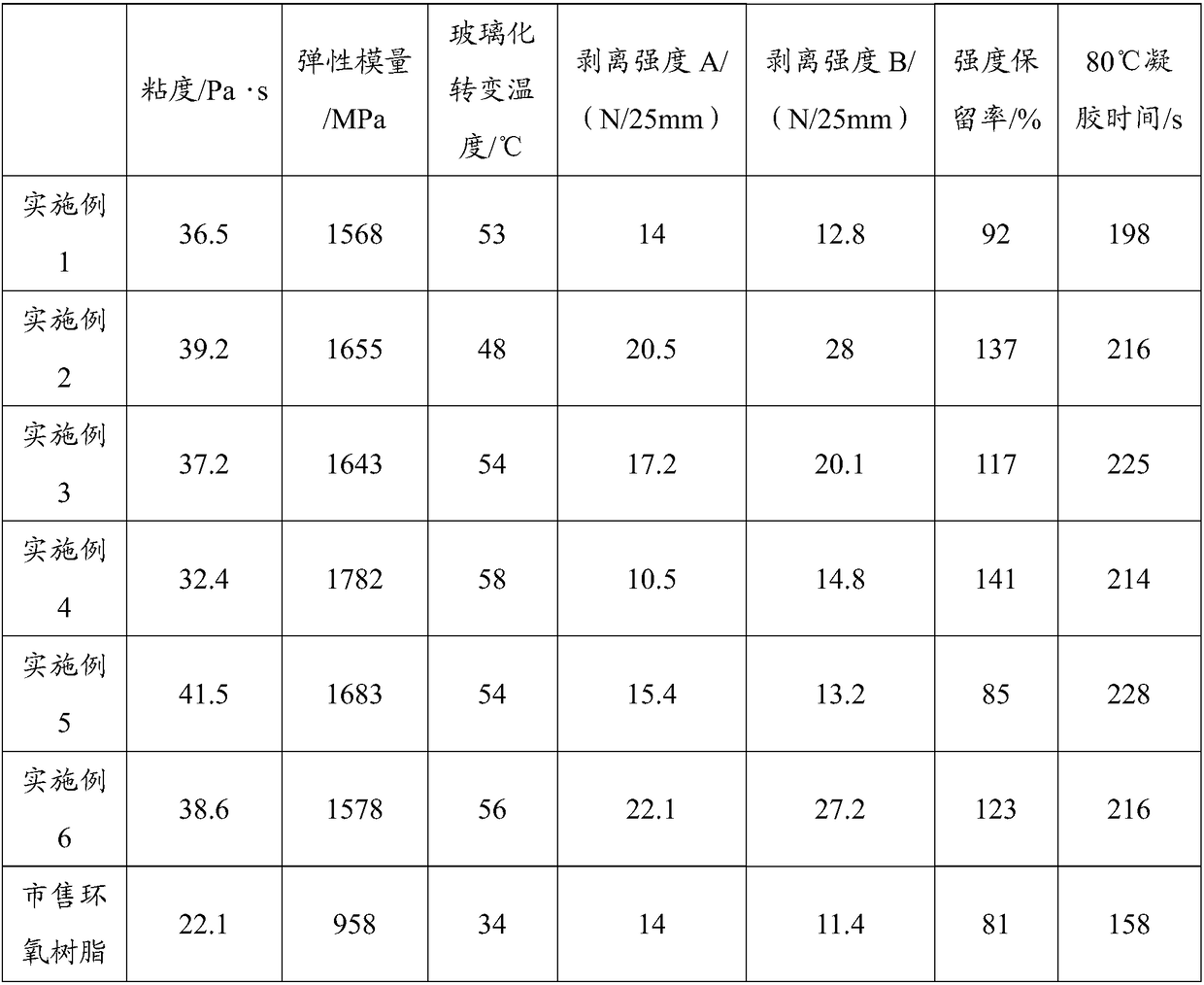

Embodiment 1

[0022] Levulinic acid and isooctyl alcohol are added in the reactor according to the molar ratio of 1:1, and then catalyst Qs-6 and thioglycolic acid of one-thousandth of the mass of levulinic acid are added, and the molar ratio of Qs-6 to thioglycolic acid is 3:1, react at the reaction temperature of 180°C for 5h, then lower the speed of 7°C / s to 20°C for 20min to obtain isooctyl levulinate. Then isooctyl levulinate and phenol are added in the reaction system according to the molar ratio of 1:4, and catalyst hydrochloric acid and cocatalyst thioglycolic acid are added, and its consumption is according to the molar ratio of hydrochloric acid and isooctyl levulinate of 4:1, thioglycolic acid The molar ratio to isooctyl levulinate is 0.02:1. At 60°C, react for 35 hours, wash with water to remove excess phenol, and obtain bisphenolate ester after drying. Add the obtained bisphenolate ester and epichlorohydrin into the reaction system according to the molar ratio of 1:6, graduall...

Embodiment 2

[0028] Add levulinic acid and isooctyl alcohol into the reactor according to the molar ratio of 1:1, and then add the catalyst p-toluenesulfonic acid and thioglycolic acid which is one percent of the mass of levulinic acid, and the moles of p-toluenesulfonic acid and thioglycolic acid The ratio is 3:1, the reaction temperature is 160°C, react for 3h, then lower the speed of 9°C / s to 22°C and react for 25min to obtain isooctyl levulinate. Then isooctyl levulinate and phenol are added in the reaction system according to the molar ratio of 1:4, and catalyst hydrochloric acid and cocatalyst thioglycolic acid are added, and its consumption is according to the molar ratio of hydrochloric acid and isooctyl levulinate of 4:1, thioglycolic acid The molar ratio to isooctyl levulinate is 0.02:1. At 70°C, react for 25 hours, wash with water to remove excess phenol, and obtain bisphenolate ester after drying. Add the obtained bisphenolate ester and epichlorohydrin into the reaction system...

Embodiment 3

[0034] Add levulinic acid and isooctyl alcohol into the reactor according to the molar ratio of 1:1, and then add catalyst tetrabutyl titanate and thioglycolic acid, which are 1% of the mass of levulinic acid, and tetrabutyl titanate and thioglycolic acid The molar ratio is 4:1, and the reaction temperature is 170° C., reacted for 3 hours, then lowered to 20° C. and reacted for 30 minutes at a rate of 10° C. / s to obtain isooctyl levulinate. Then isooctyl levulinate and phenol are added in the reaction system according to the molar ratio of 1:4, and catalyst hydrochloric acid and cocatalyst thioglycolic acid are added, and its consumption is according to the molar ratio of hydrochloric acid and isooctyl levulinate of 4:1, thioglycolic acid The molar ratio to isooctyl levulinate is 0.02:1. At 70°C, react for 15 hours, wash with water to remove excess phenol, and obtain bisphenolate ester after drying. Add the obtained bisphenolate ester and epichlorohydrin into the reaction sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com