Method used for removing hydrazine hydrochloride in tert-butylhydrazine hydrochloride

A technology of tert-butylhydrazine and hydrochloride, which is applied in the field of pesticide intermediates and pesticides, can solve the problems of increasing the difficulty of purification of downstream products, high solubility of tert-butylhydrazine hydrochloride, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

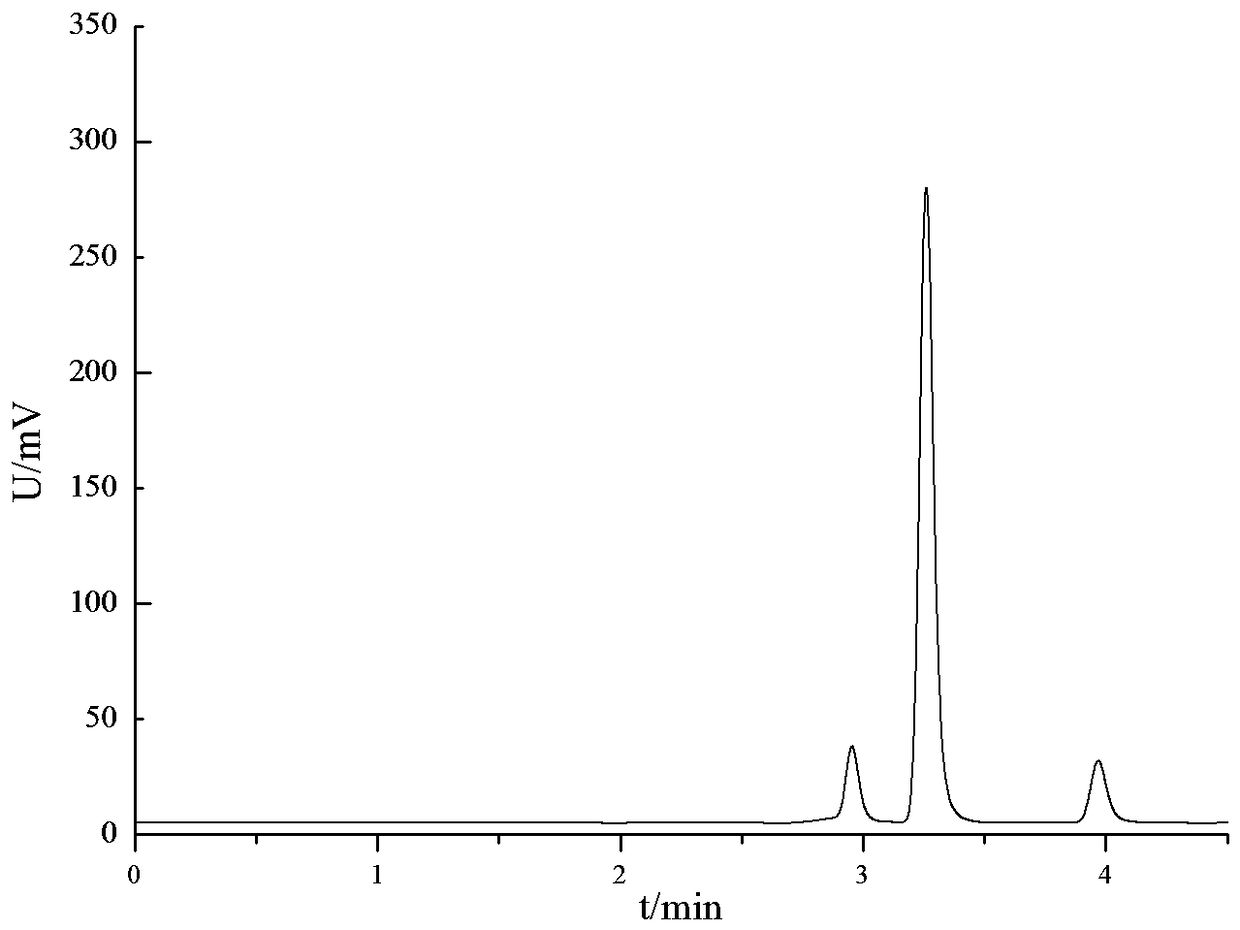

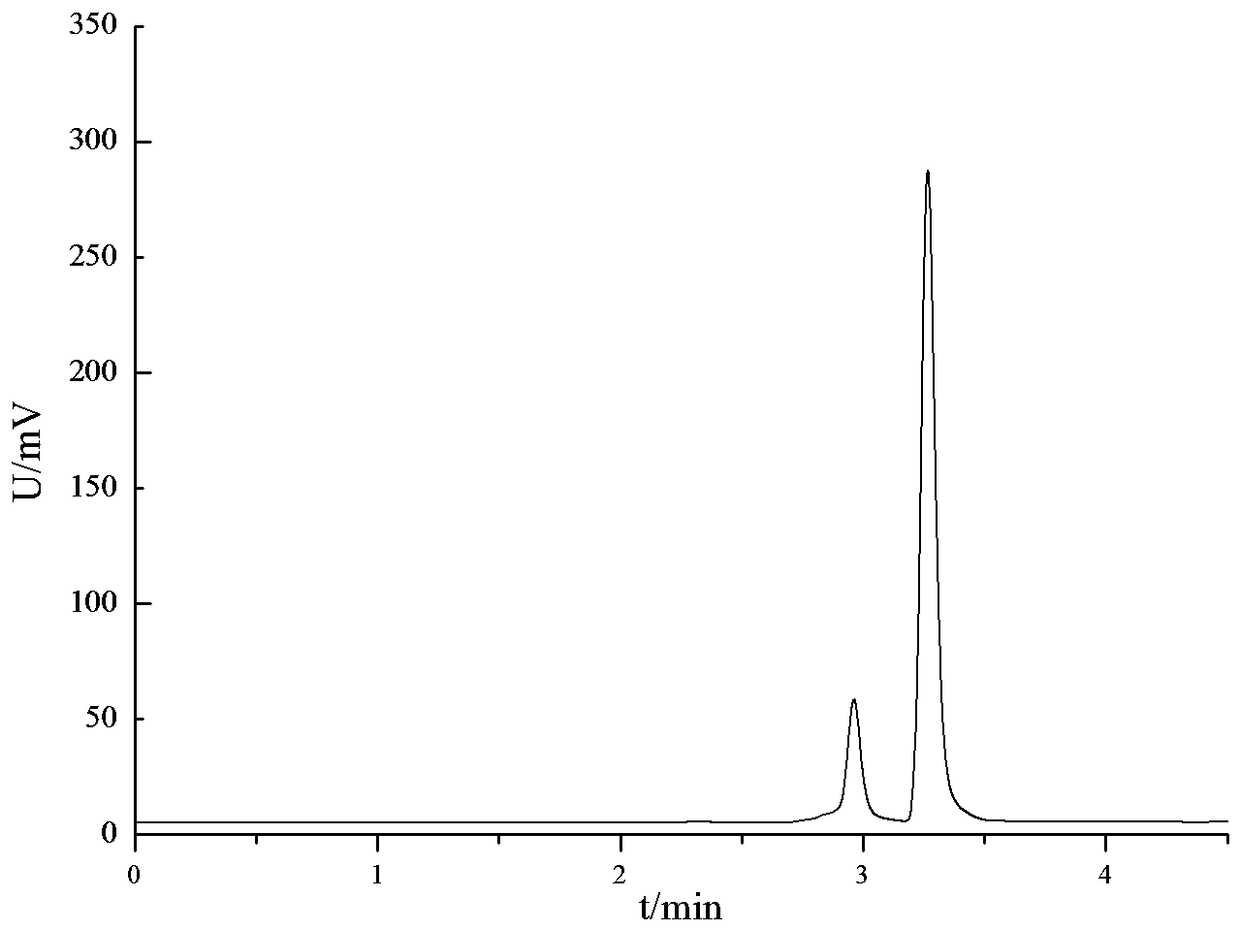

[0020] In a 100mL flask equipped with a stirring device and a reflux device, add 20mL of absolute ethanol, 6.00g of 89.36% (w / w) tert-butylhydrazine hydrochloride, stir in a water bath at 60°C to dissolve, cool to room temperature, and add bicarbonate Ammonium 0.90g, reacted at room temperature for 2 hours, filtered after the reaction, and washed the filter cake with a small amount of ethanol. The filtrate was recovered and applied once, and the operation method was the same as above. The filter cake was dried to obtain a total of 10.48 g of white powder. As determined by high performance liquid chromatography, the content of tert-butylhydrazine hydrochloride was 91.86%, and the yield was 89.78%.

Embodiment 2

[0022] In a 100mL flask equipped with a stirring device and a reflux device, add 20mL of 98% (v / v) ethanol, 8.00g of 89.36% (w / w) tert-butylhydrazine hydrochloride, stir in a water bath at 70°C to dissolve, and cool to At room temperature, add 1.60 g of ammonium bicarbonate, react at room temperature for 1 hour, filter after the reaction, and wash the filter cake with a small amount of ethanol. The filtrate was recovered and applied mechanically twice, and the operation method was the same as above. The filter cake was dried to obtain a total of 19.80 g of white powder. As determined by high performance liquid chromatography, the content of tert-butylhydrazine hydrochloride was 90.72%, and the yield was 92.32%.

Embodiment 3

[0024] In a 100mL flask equipped with a stirring device and a reflux device, add 20mL of 95% (v / v) ethanol, 10.00g of 89.36% (w / w) tert-butylhydrazine hydrochloride, stir in a water bath at 80°C to dissolve, and cool to At room temperature, add 2.00 g of ammonium bicarbonate, react at room temperature for 1 hour, filter after the reaction, and wash the filter cake with a small amount of ethanol. The filtrate was recovered and applied mechanically 3 times, and the operation method was the same as above. The filter cake was dried to obtain a total of 33.56 g of white powder. As determined by high performance liquid chromatography, the content of tert-butylhydrazine hydrochloride was 89.14%, and the yield was 93.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com