Porous three-dimensional phosphorene and its preparation method and application

A technology of three-dimensional phosphorene and black phosphorene, which is applied in the field of inorganic nanomaterials, can solve the problems of hindering application and reducing the contact area of electrolyte, and achieve the effect of increasing wettability, high utilization rate and stable three-dimensional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

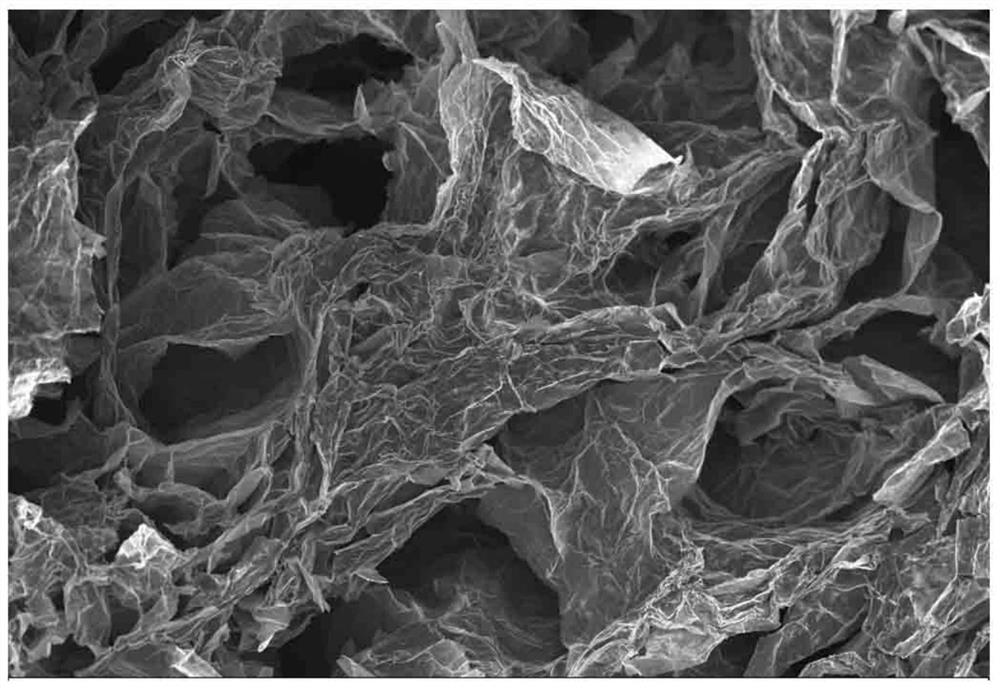

[0049] A method for preparing porous three-dimensional black phosphorene, comprising the steps of:

[0050] (1) Use 1*0.5*0.05cm black phosphorus crystal as cathode, 2*2*0.05cm platinum sheet as auxiliary electrode, N,N-dimethylformamide as intercalation agent, tetrabutyl Ammonium bromide is used as an auxiliary intercalation agent, the concentration of tetrabutylammonium bromide is 0.01M, and an H-type electrolytic cell is assembled;

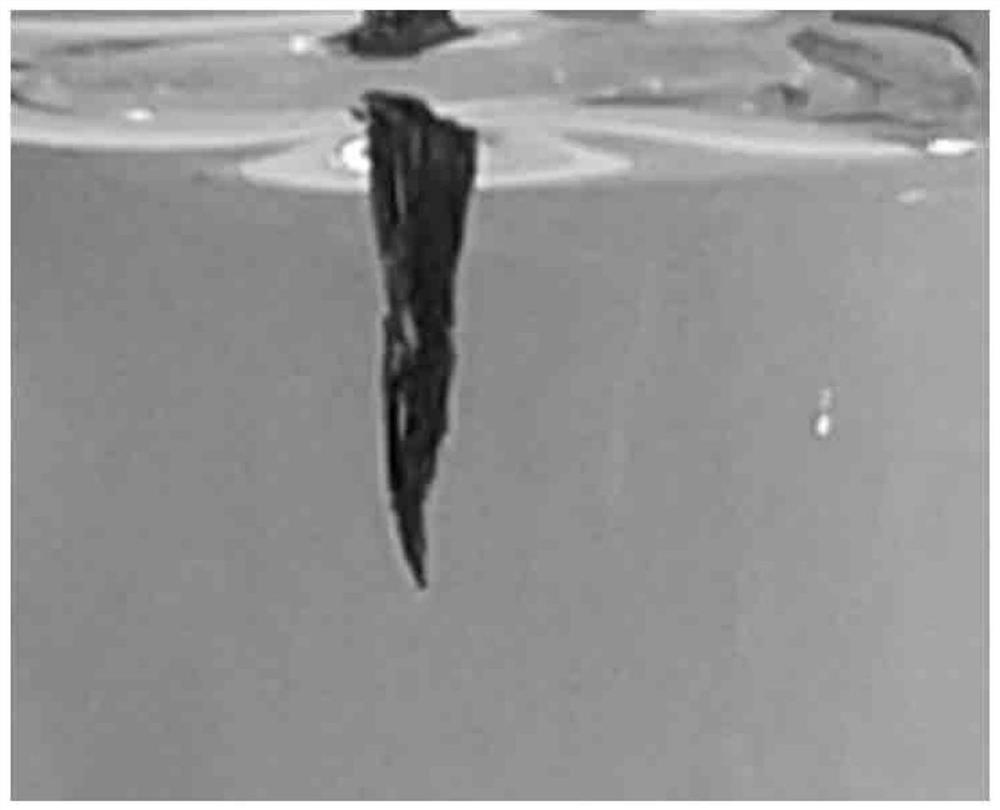

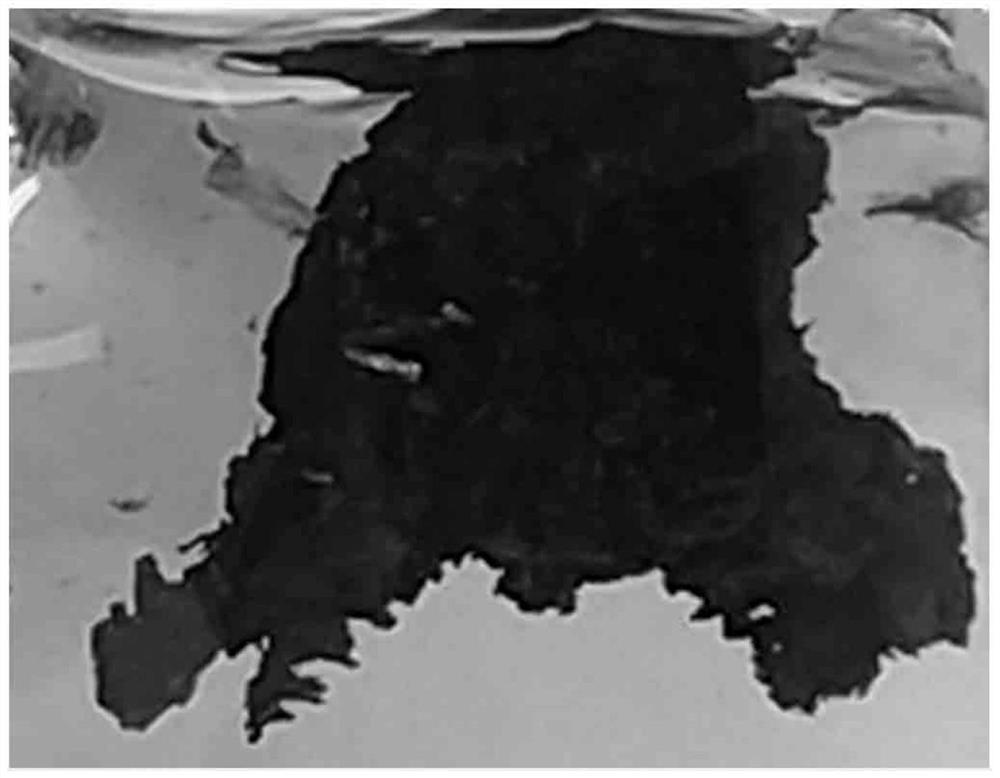

[0051] (2) Using a direct current power supply to expand the black phosphorus crystal for 1min under the condition of a voltage of 10V, after the expansion is completed, the black phosphorus with a rough surface and doubled volume is obtained;

[0052] (3) Use a 400-mesh filter screen to filter the expanded black phosphorus, then use N,N-dimethylformamide, ethanol, acetone, and cyclohexane to wash the expanded black phosphorus for 3 times, and then wash the black phosphorus Phosphorus was soaked in cyclohexane for 30 minutes, then placed in li...

Embodiment 2

[0058] A method for preparing porous three-dimensional black phosphorene, comprising the steps of:

[0059] (1) Use 2*1*0.05cm black phosphorus crystal as cathode, 2*2*0.05cm carbon cloth as auxiliary electrode, N-methylpyrrolidone as intercalation agent, tetrapentyl ammonium iodide as Auxiliary intercalation agent, the concentration of tetrapentyl ammonium iodide is 0.025M, assembled into an H-type electrolytic cell;

[0060] (2) Adopting DC power supply to carry out expansion treatment to black phosphorus crystal under the condition of voltage of 10V for 3min, obtain rough surface and black phosphorus with doubled volume after the expansion is completed;

[0061] (3) Adopt 400 mesh filter screens to filter the expanded black phosphorus, then use N-methylpyrrolidone, ethanol, acetone, carbon tetrachloride to wash the expanded black phosphorus 3 times respectively, then place the washed black phosphorus in Soak in carbon tetrachloride for 30 minutes, then place in liquid nitr...

Embodiment 3

[0065] A method for preparing porous three-dimensional black phosphorene, comprising the steps of:

[0066] (1) Use 2.5*1.5*0.05cm black phosphorus crystal as cathode, 3*3*0.05cm titanium mesh as auxiliary electrode, dimethyl sulfoxide as intercalation agent, and tetrahexylammonium bromide as auxiliary The intercalation agent, the concentration of tetrahexyl ammonium bromide is 0.05M, assembled into an H-type electrolytic cell;

[0067] (2) Adopting DC power supply to expand the black phosphorus crystal for 5min under the condition of voltage of 20V, after the expansion is completed, obtain the black phosphorus with rough surface and multiplied volume;

[0068] (3) Use 400 mesh filter screens to filter the expanded black phosphorus, then use dimethyl sulfoxide, ethanol, acetone, and cyclohexane to wash the expanded black phosphorus for 3 times, then place the washed black phosphorus in the ring Soak in hexane for 30 minutes, then place in liquid nitrogen and freeze at -50°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com