Coaxial 3D printing process and equipment

A 3D printing, coaxial technology, applied in the field of 3D printing, can solve the problem of difficult to meet market demand, and achieve the effect of reducing the consumption of consumables, reducing the weight of products, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

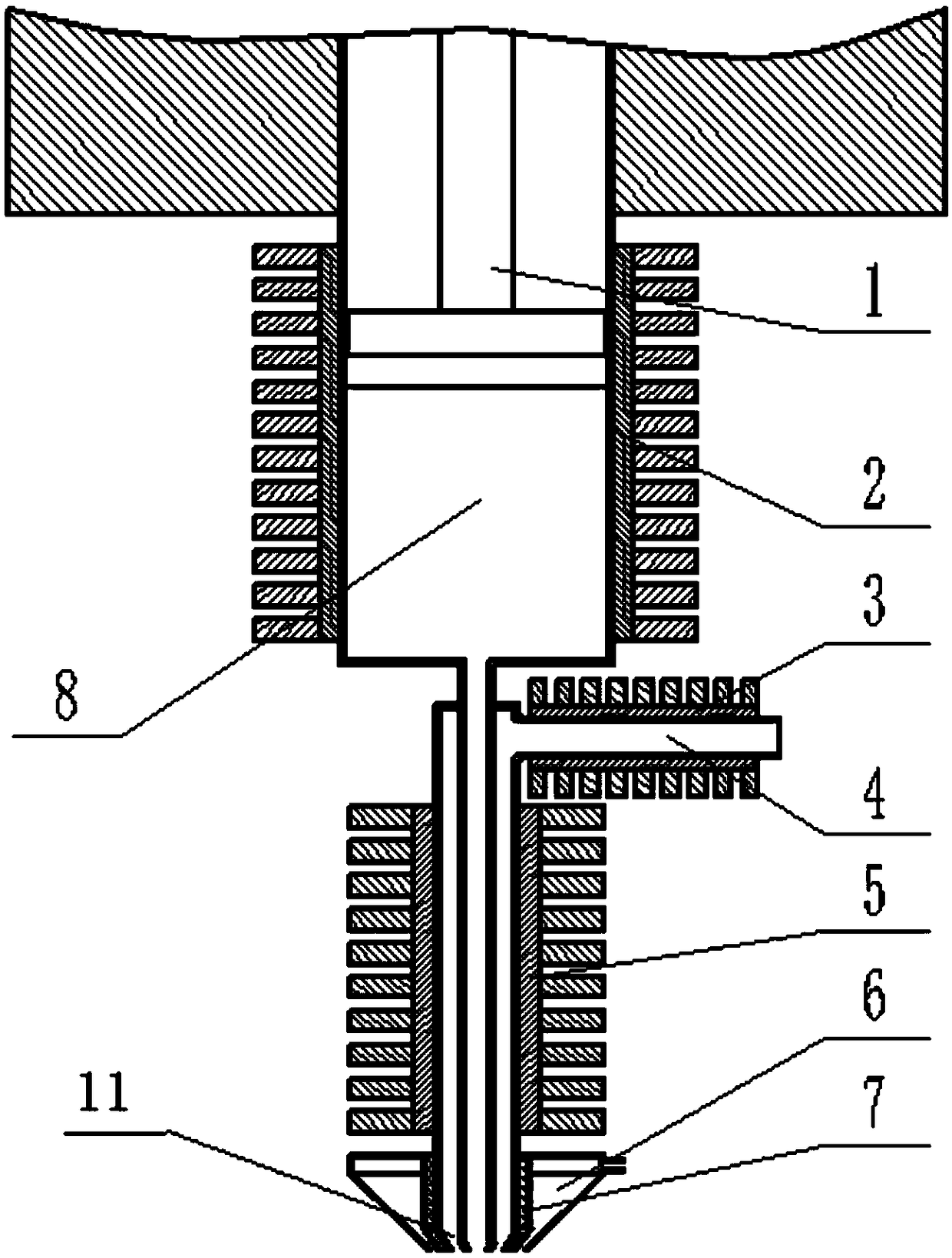

[0020] A kind of coaxial 3D printing equipment of the present invention, such as figure 1 As shown, it mainly includes piston 1, inner layer heating jacket 2, outer layer heating jacket 3, outer layer material channel 4, heat preservation jacket 5, annular airflow outlet sleeve 6, heat insulation layer 7 and piston barrel 8, and piston barrel 8 is placed Enter the inner layer material 10, the inner layer heating jacket 2 will heat and preheat the melted inner layer material 10, and the outer layer heating jacket 3 will heat and melt the outer layer material 9 located in the outer layer material channel 4, and the piston 1 will compress it during the printing process. The inner layer material 10 enters the range of the insulation cover 5; the outer layer material 9 is introduced into the outer layer material channel 4 through a piston extruder or a screw extruder; the insulation cover 5 is used to make the coaxial The material has good fluidity, so that it can be extruded smoot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com