Soft mechanical arm based on SMA springs

A manipulator and software technology, applied in the field of manipulators, can solve the problems of difficult manufacturing process, short service life and complexity, and achieve the effect of simple driving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

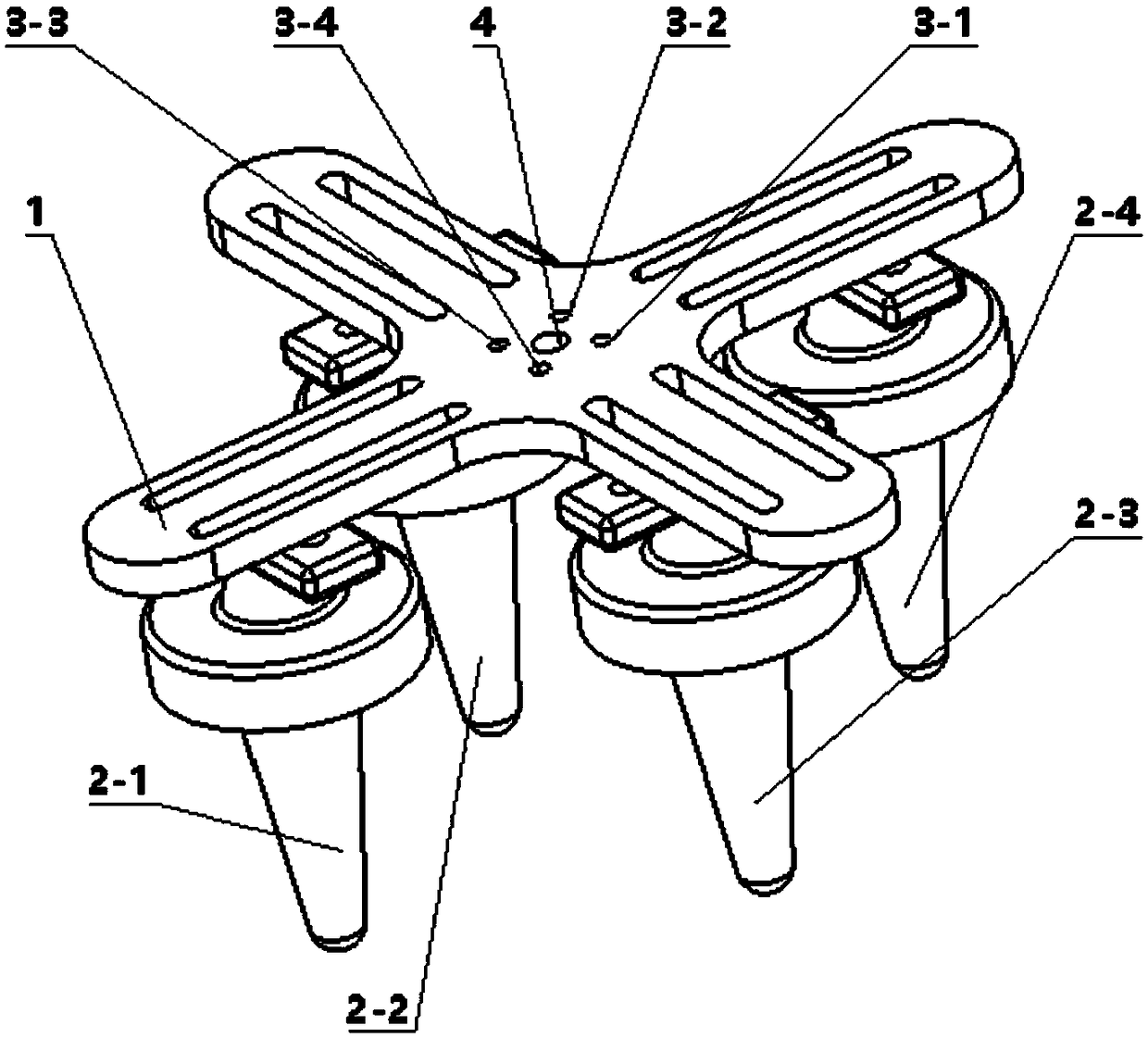

[0046] A kind of soft manipulator based on the SMA spring of this embodiment, the internal shape memory alloy SMA spring is used as the power source, and the current flows through the SMA spring. This process generates Joule heat, and the heat causes the SMA spring to deform in a one-dimensional direction. Using the function of two SMA springs, it is converted into the effect that the soft claws point to different directions, and due to the special properties of SMA springs, its resistivity changes with temperature, and the sampling circuit is used to convert the resistivity into voltage or current through the single-chip computer. Take this analog quantity to design the control system. The strain and stress generated in this process are the basis for the deformation and gripping force of the soft manipulator. The outside of the SMA spring is a soft silicone that wraps the SMA spring and is driven to deform as the SMA spring deforms. Finally, the four soft silicone fingers are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com