Mistake-proofing tool for connecting piece machining

A connecting piece and error-proofing technology, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve problems such as clamping errors, low production efficiency, and affecting product quality, so as to reduce production costs and avoid processing errors , Improve the effect of processing accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

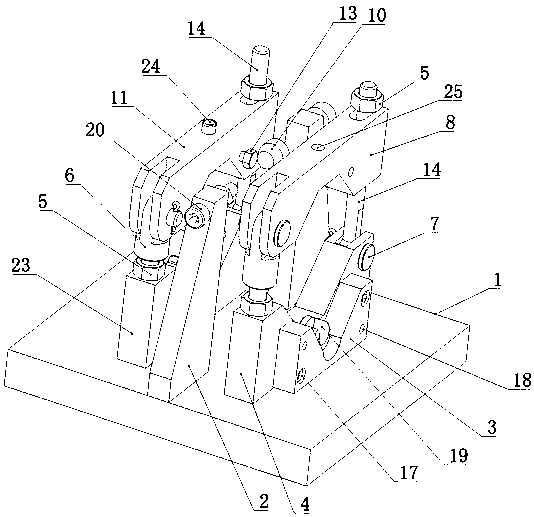

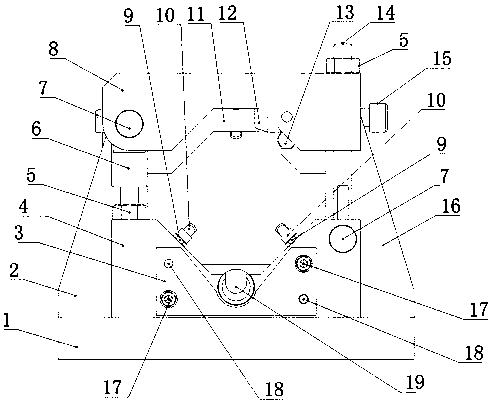

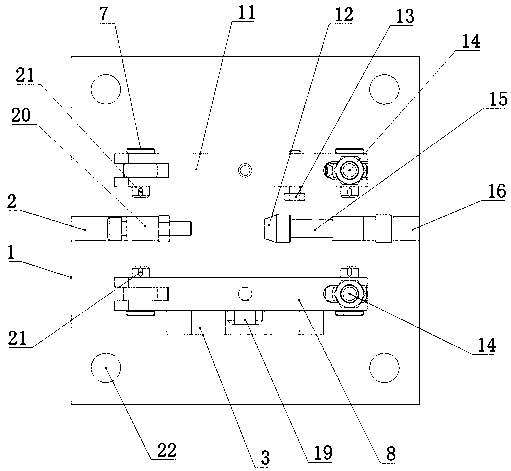

[0019] The present invention will be further explained below in conjunction with the drawings:

[0020] Such as figure 1 with 3 As shown, the present invention provides a mistake-proof tooling for connection processing, which includes a base 1, on which a first supporting plate 2 and a second supporting plate 16 are oppositely arranged, and the first supporting plate 2 and the second supporting plate 16 The sides are respectively provided with a fixed V-shaped block 4 and an adjustable V-shaped block 23, the outer side wall of the fixed V-shaped block 4 is connected with a contour template 3, the contour template 3 is V-shaped and the taper is smaller than or greater than the taper of the fixed V-shaped block 4; Before clamping the workpiece, by installing contour templates with different tapers on the outer side wall of the fixed V-block, the position of the workpiece can be preset. When clamping other similar workpieces, interference will occur and the workpiece cannot be loaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com