Intelligent assembling system for purifying and filtering water cup sealing part

A technology for sealing components and assembly systems, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as inability to meet market demand and low efficiency, and achieve the goal of reducing the probability of manual operation errors, reducing investment and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

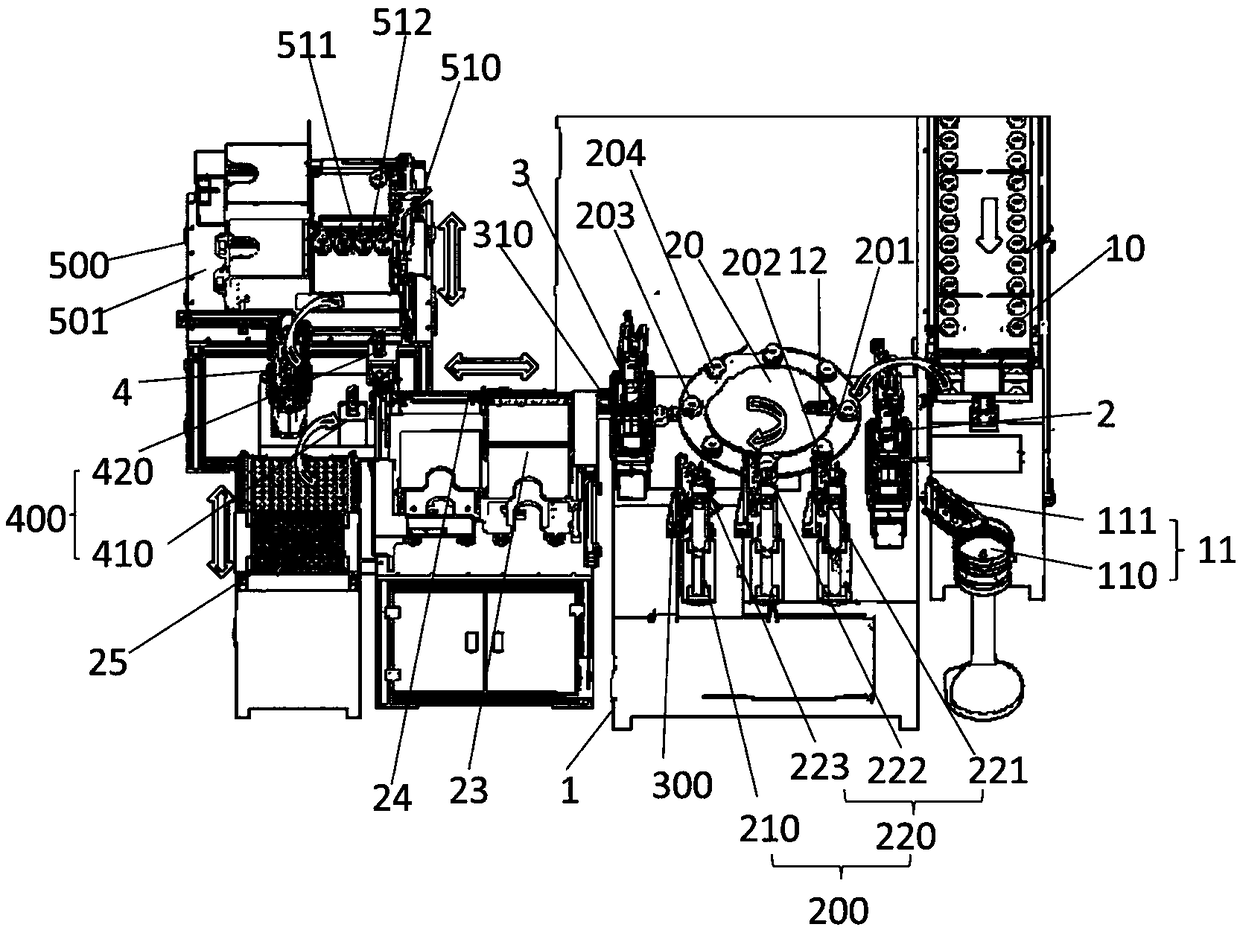

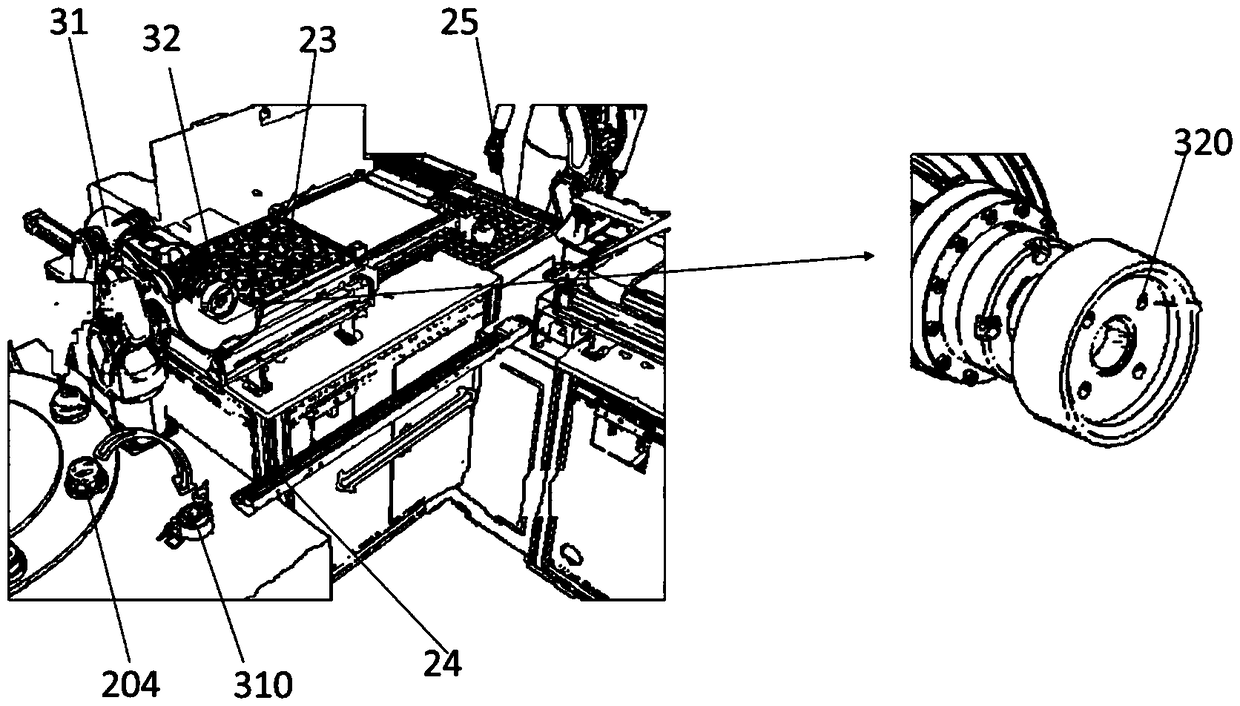

[0033] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

[0034] The intelligent assembly system proposed by the present invention is used to assemble the sealing parts of the purified and filtered water cup. The sealed parts of the purified and filtered water cup mainly include a base, an O-ring assembly in the base, a bottle cap and a bottle mouth, wherein the O-ring assembly includes Three O-rings; the main process of assembly can be briefly expressed as follows: the base is injected into the injection molding machine and fed, and the O-ring components are fed separately through its feeding mechanism, and are respectively installed inside the base, at the upper end and at the lower end; then , Tighten the cap and the base, and then press the mouth of the bottle to complete the assembly.

[0035] figure 1A schematic diagram of the overall structure of the intelligent assembly syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com