Metal filament additive manufacturing device

An additive manufacturing and metal filament technology, applied in the field of metal filament additive manufacturing devices, can solve problems such as arcing splash, poor substrate bonding, etc., to eliminate arc and spark phenomenon, avoid printing failure or atmospheric pressure Good effect of stable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

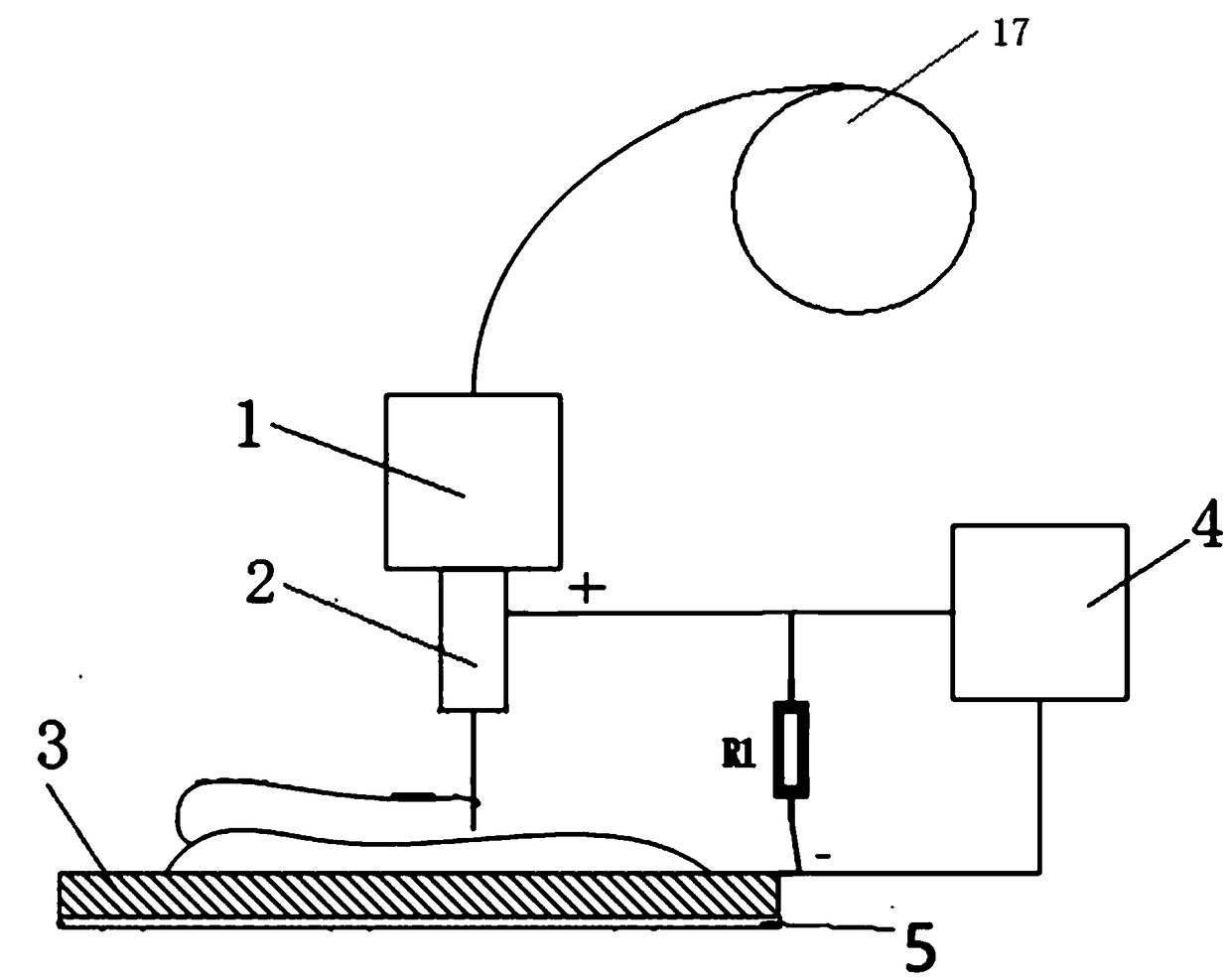

[0030] Such as figure 1 As shown, the principle of the present invention is based on the fact that the metal wire material will generate resistance heat after being energized, and the metal wire material will be melted and piled up to form through the resistance heat. The positive pole of the power supply 4, the metal substrate 3 is connected to the negative pole of the power supply 4, the top of the metal wire 17 and the substrate 3 form a circuit, and a certain form of current is passed through to instantly melt the end of the metal wire 17. After melting, the metal droplets are due to gravity and surface The effect of tension is deposited on the substrate 3, and with the movement of the substrate 3 and the continuous delivery of the wire, stacked metal parts can be formed on the substrate 3, realizing metal additive manufacturing. However, during the printing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com