Rapid cleaning device of cement barrel for building

A cleaning device, a technology for construction, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as manual cleaning and cleaning, achieve easy assembly and disassembly, easy to fasten fixing, avoid manual The effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

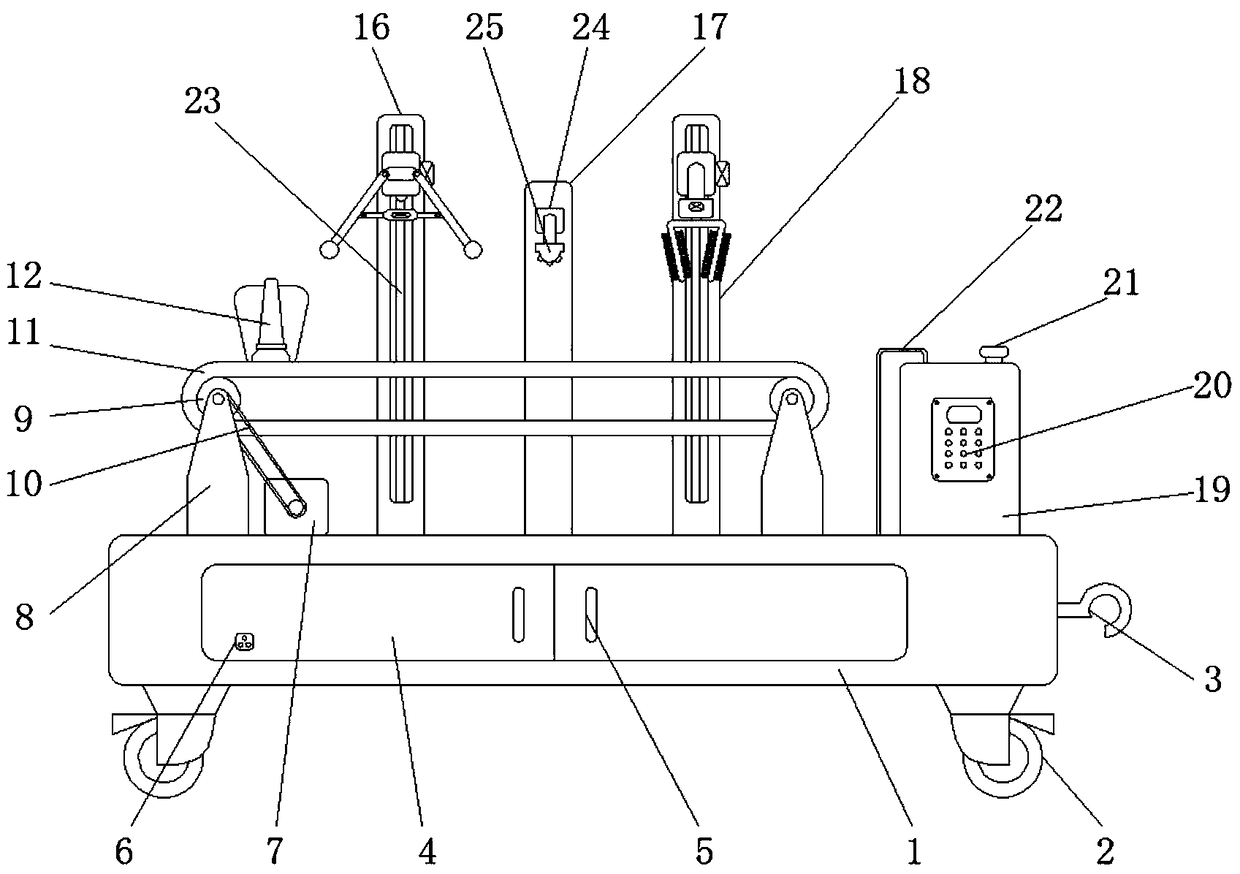

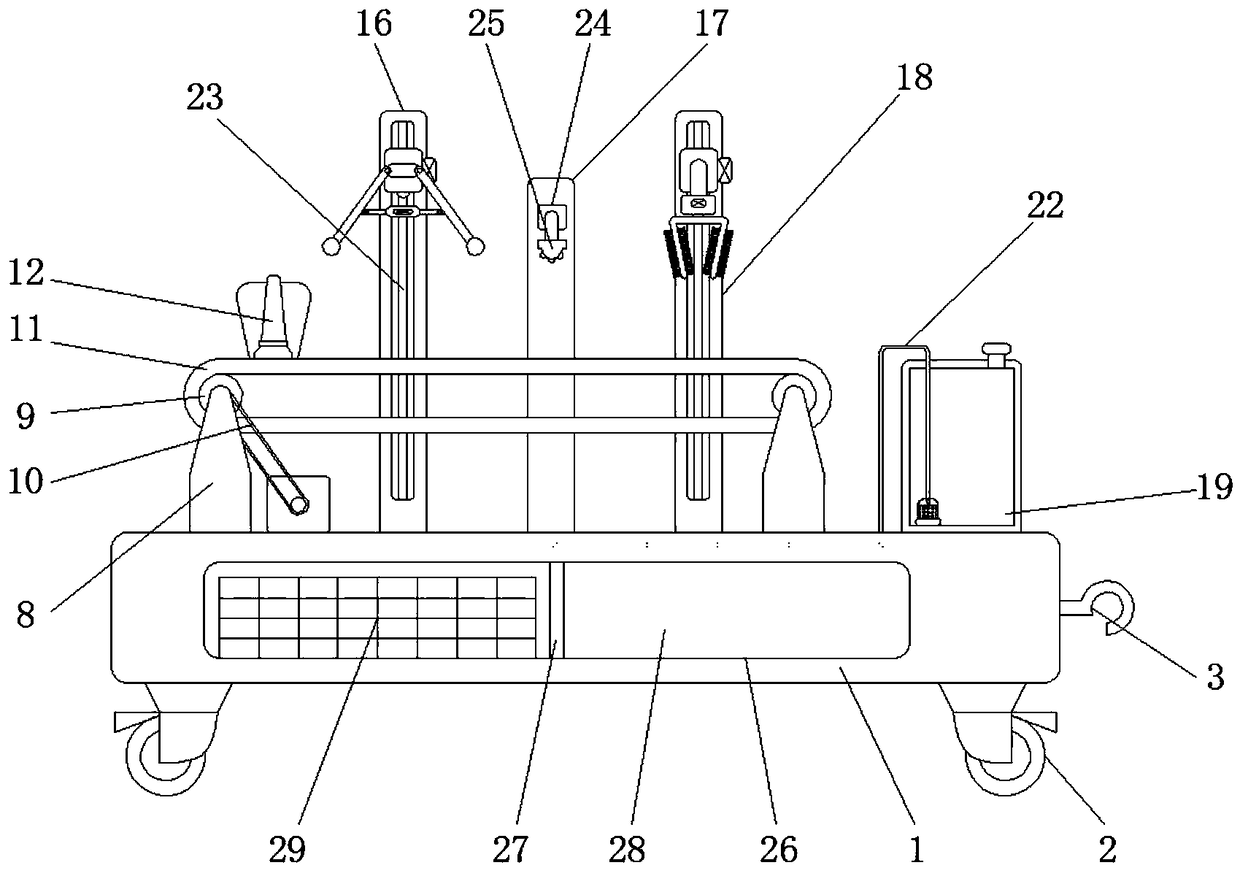

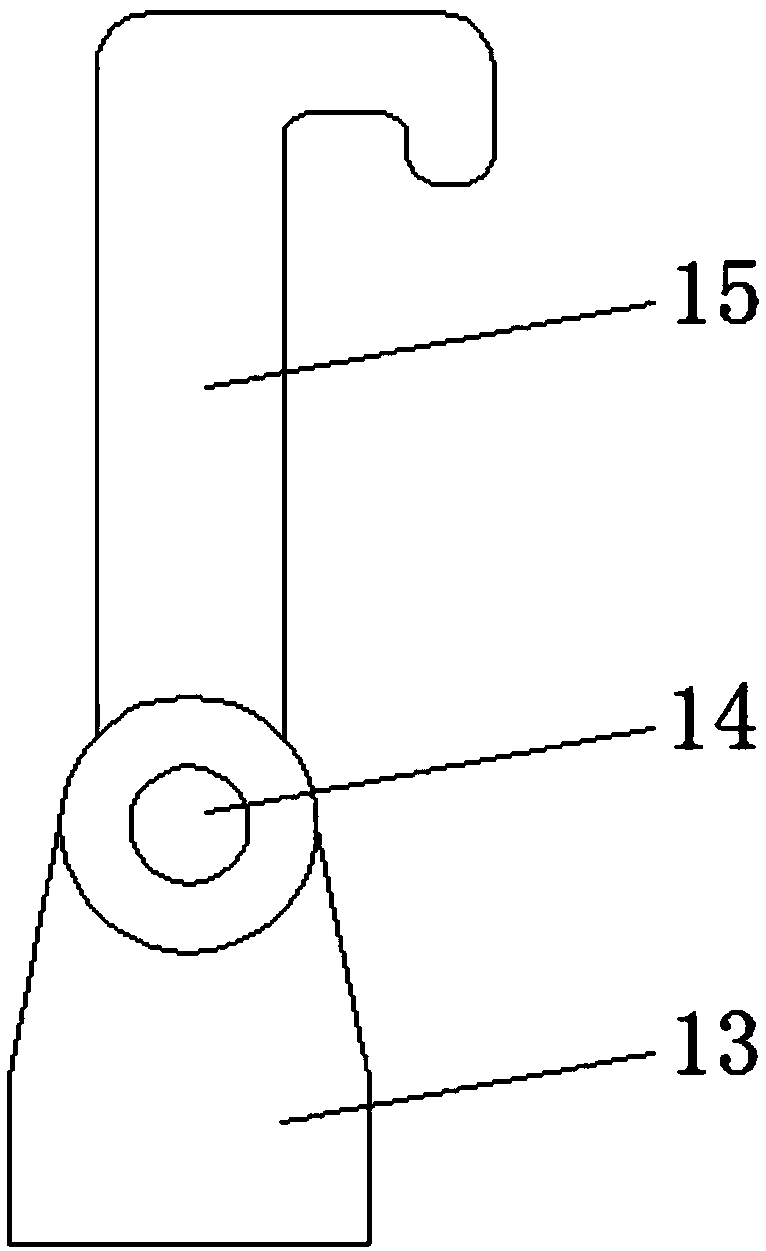

[0023] according to Figure 1-5 A quick cleaning device for cement buckets for construction is shown, including a base 1, a cement bucket fixing assembly 12, a cleaning liquid storage tank 19, a storage cavity 28 and a battery pack 29, and the bottom of the base 1 is equipped with universal wheels 2, By installing universal wheels 2 at the bottom of the base 1, the cleaning device as a whole can be moved, which is convenient for actual use and movement. The surface on one side of the base 1 is welded with a traction hook 3. By being provided with a traction hook 3, It can make the device easy to pull and move when in use. A cleaning liquid storage tank 19 is installed on the side abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com