Design method of a heavy-duty diesel vehicle exhaust fine dust treatment device

A treatment device and heavy-duty diesel technology, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems that dust collectors are difficult to meet the pollution prevention and control of mobile sources, and achieve the effect of simple design and reliable technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

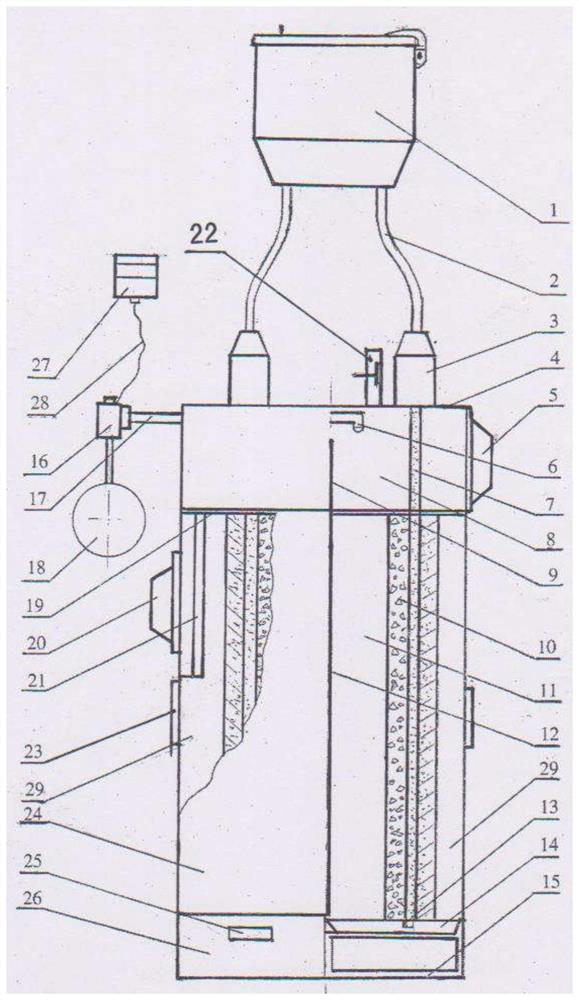

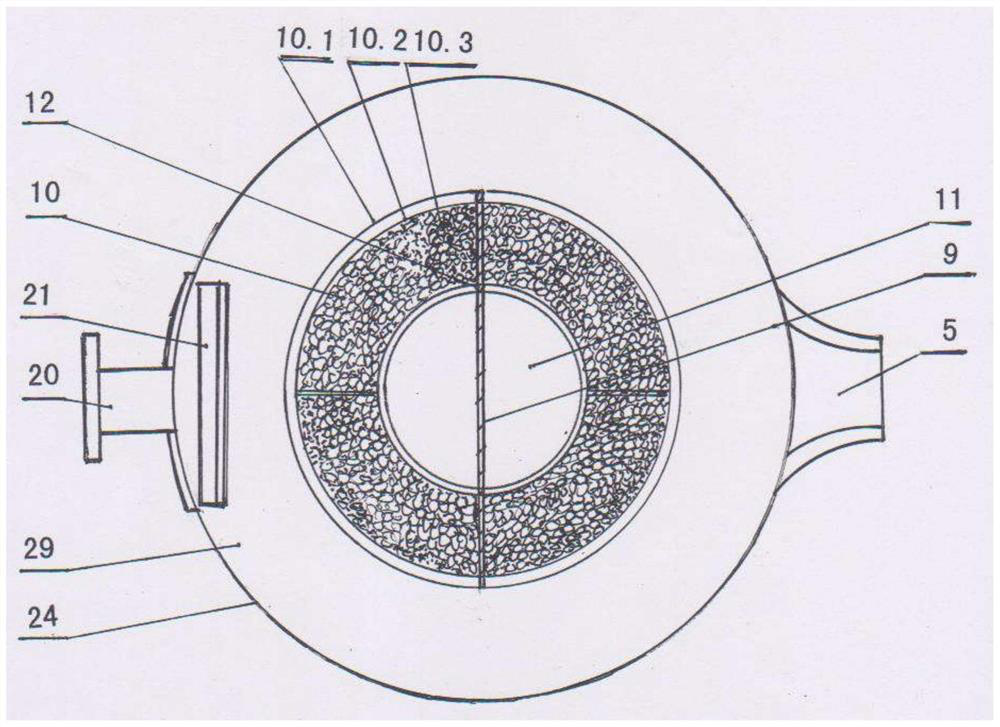

Embodiment 1

[0031] The design method of a heavy-duty diesel vehicle exhaust fine dust treatment device according to Embodiment 1 of the present invention includes the overall structural design of the exhaust gas fine dust treatment device and the specific design of each component, and its special feature is that the exhaust gas fine dust The design method of the treatment device is: based on the operation status and technical parameters of heavy-duty diesel vehicles, it can effectively treat the exhaust gas dust in the process of ensuring the normal operation of the vehicle, and at the same time remove the accumulated dust in the treatment device in time and collect it in a special In the dust box of the exhaust gas dust box, the treated exhaust gas dust meets the national exhaust gas fine dust discharge standard; the overall structure design method of the tail gas fine dust treatment device (see figure 1 , figure 2 ) is: set a dust treatment device with a housing 24 and set an air inlet...

Embodiment 2

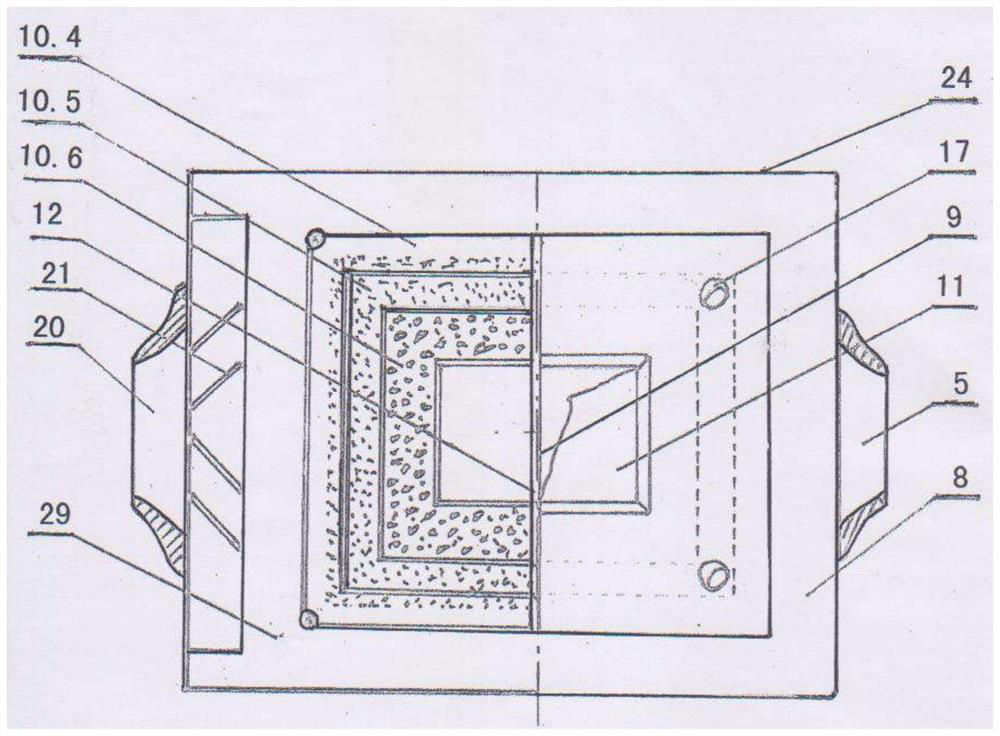

[0043] The design method of a heavy-duty diesel vehicle exhaust fine dust treatment device according to Embodiment 2 of the present invention includes the overall structural design of the exhaust gas fine dust treatment device and the specific design of each component, and its special feature is that the exhaust gas fine dust The design method of the treatment device is: based on the operation status and technical parameters of heavy-duty diesel vehicles, it can effectively treat the exhaust gas dust in the process of ensuring the normal operation of the vehicle, and at the same time remove the accumulated dust in the treatment device in time and collect it in a special In the dust box of the exhaust gas dust box, the treated exhaust gas dust meets the national exhaust gas fine dust discharge standard; the overall structure design method of the tail gas fine dust treatment device (see figure 1 , image 3 ) is: set a dust treatment device with a housing 24 and set an air inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com