Multi-section type heating non-combustion cigarette

A heat-not-burn, multi-stage technology, applied in tobacco, smoker’s supplies, applications, etc., can solve the problems of flue gas difference, low heat energy utilization rate, large investment, etc., to save production costs, increase heating area, and shorten heating speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

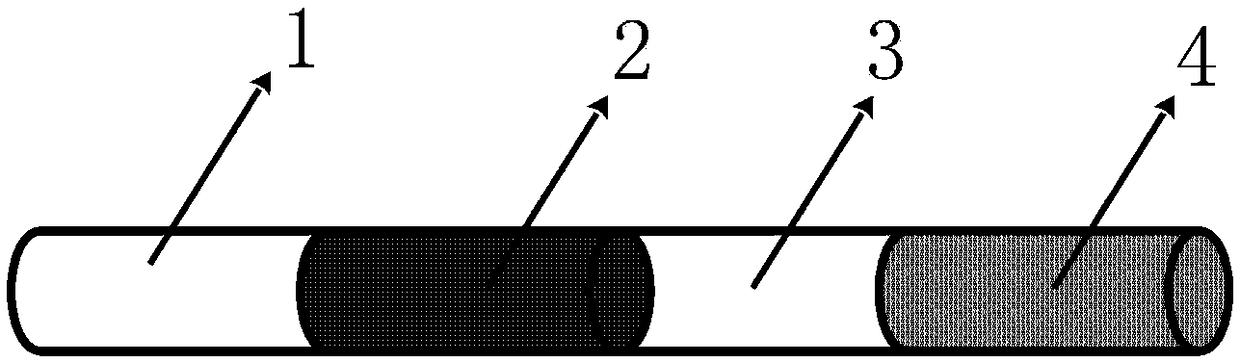

[0037] The design of multi-stage heat-not-burn cigarettes is as follows:

[0038] The second hollow pipe section 1 is a paper rigid hollow pipe composited with multi-layer paper, and is loaded with propylene glycol and flavor and fragrance additives;

[0039] The smoking base material in the smoking section 2 is reconstituted tobacco leaves, and the cigarette paper is flavored cigarette paper;

[0040] The first hollow pipe section 3 is a paper hard hollow pipe;

[0041] The cooling filter section 4 is a three-dimensional network structure made of polylactic acid tow, and its longitudinal porosity is 60%.

[0042] The cooling and filtering section 4 , the first hollow tube section 3 , the smoking section 2 and the second hollow tube section 1 are rolled into cigarettes by using a single cigarette paper to simultaneously roll the four sections into shape.

[0043] Smoking test of multi-stage heat-not-burn cigarettes:

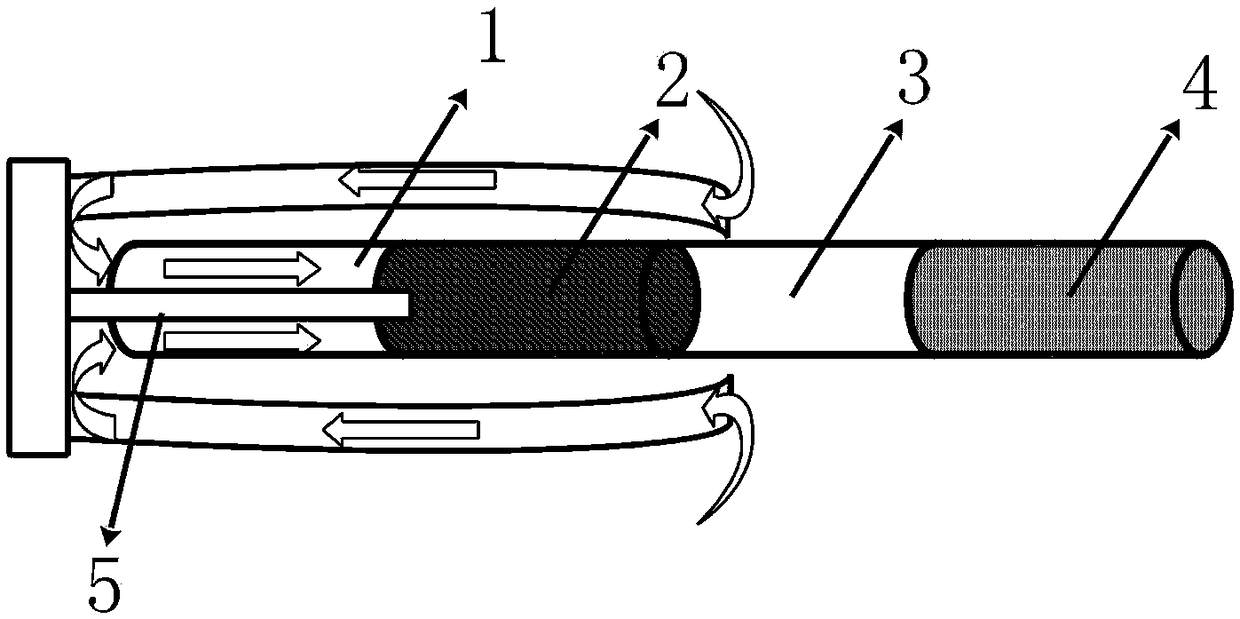

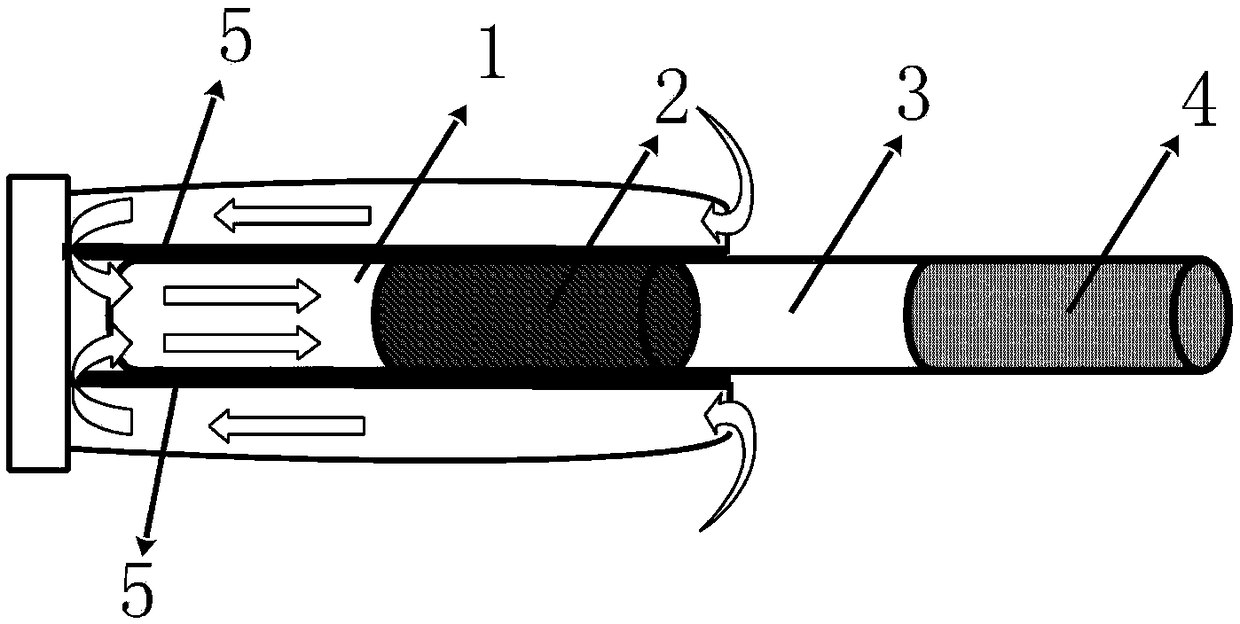

[0044] The cigarettes prepared above were stuffed into s...

Embodiment 2

[0046] Cigarettes are designed as follows:

[0047] The second hollow tube section 1 is a rigid hollow tube made of non-woven carbon fiber mat, and is loaded with glycerol;

[0048] The smoking matrix material in the middle of the smoking section 2 is reconstituted tobacco leaves, and the cigarette paper is cigarette paper containing microcapsules;

[0049] The first hollow pipe section 3 is a paper hard hollow pipe;

[0050] The cooling filter section 4 is a three-dimensional network structure made of polylactic acid tow, and its longitudinal porosity is 50%.

[0051] The cooling and filtering section 4 , the first hollow tube section 3 , the smoking section 2 and the second hollow tube section 1 are rolled into cigarettes by using a single cigarette paper to roll the four sections at the same time.

[0052] Smoking test of multi-stage heat-not-burn cigarettes:

[0053] Insert the above-prepared cigarettes into a center-heated smoking set of the same size (as attached fig...

Embodiment 3

[0055] Cigarettes are designed as follows:

[0056] The second hollow tube section 1 is a rigid hollow tube made of aluminum foil and paper loaded with pentadecane;

[0057] The smoking base material in the smoking section 2 is a mixture of reconstituted tobacco leaves and shredded tobacco, and the cigarette paper is ordinary cigarette paper;

[0058] The first hollow tube section 3 is a hollow tube made of a rigid polymer;

[0059] The cooling and filtering section 4 is a polymer rod with through holes formed after polyethylene foaming, and its longitudinal porosity is 70%.

[0060] The cooling and filtering section 4 , the first hollow tube section 3 , the smoking section 2 and the second hollow tube section 1 are rolled separately and then combined again to form cigarettes.

[0061] Smoking test of multi-stage heat-not-burn cigarettes:

[0062] The above-mentioned prepared cigarettes were stuffed into the same size circumferentially heated smoking utensils (as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com