Preparation method breakfast soft-boiled eggs

A breakfast egg and fluffy technology is applied in the field of preparing fluffy breakfast eggs, which can solve the problems of inaccurate process, inability to large-scale industrial production, inability to perform sterilization, etc., and achieves short marinating time, stable quality of finished products, and production saving. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Wash fresh eggs and immerse them in a pickling solution containing 20% salt and 1% sodium hydroxide at 20±3°C for 3 days; and fresh eggs and pickling solution The mass ratio is 3-3.5:5.

[0024] (2) Preheat the pickled eggs in 75°C water for 2 minutes, then boil them in 105°C salt water with a mass concentration of 20% for 4 minutes, then wash the surface salt in 50°C warm water and cooled to 85°C on the surface of the eggshell;

[0025] (3) Immerse the eggs, which have been cleaned of surface salt and dried and the temperature is higher than 80°C, in nano-Ag@SiO at a temperature of 75°C. 2 The modified PVA coating solution is taken out and air-dried to form a complete coating film, which is then made into a coated film packaged soft-boiled breakfast egg.

[0026] Nano Ag@SiO 2 The preparation of modified PVA coating liquid is as follows:

[0027] (a) Disperse nano-Ag (1mL) in ethanol (20mL) and add ammonia water (3mL) and TEOS (8μL) sequentially while stirrin...

Embodiment 2

[0036] (1) Wash fresh eggs and immerse them in a pickling solution containing 25% salt and 2% sodium hydroxide at 20±3°C for 3 days; and fresh eggs and pickling solution The mass ratio is 3-3.5:5.

[0037] (2) Preheat the marinated eggs in 82°C water for 2 minutes, then boil them in salt water with a mass concentration of 25% table salt at 110°C for different times, and then wash the surface salt in 55°C warm water and cooled to 85°C on the surface of the eggshell;

[0038] (3) Immerse the egg with a temperature higher than 80°C after washing the surface salt and drying it in the nano-Ag@SiO with a nanometer temperature of 80°C 2 The modified PVA coating solution is taken out and air-dried to form a complete coating film, which is then made into a coated film packaged soft-boiled breakfast egg.

[0039] Nano Ag@SiO 2 The preparation of modified PVA coating solution is as in case 1

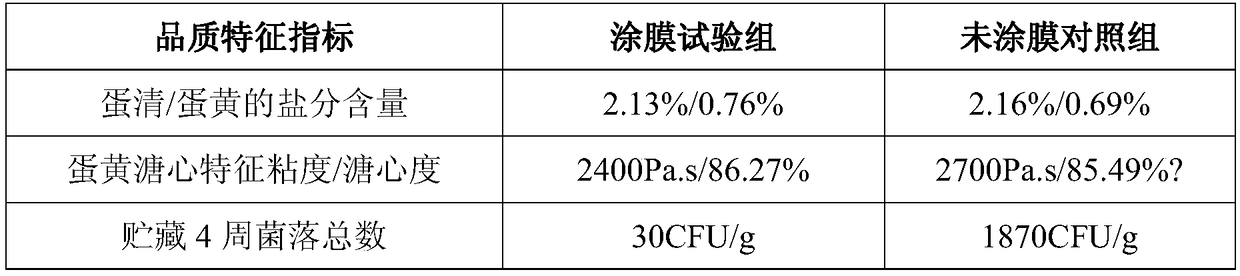

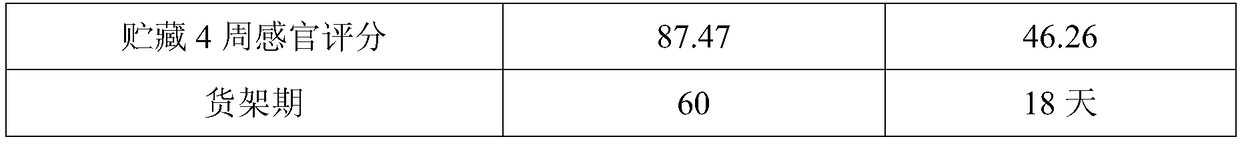

[0040] Table 2 The quality characteristic index of embodiment 2 soft-boiled breakfast eggs:...

Embodiment 3

[0043] (1) Wash and immerse fresh eggs in a pickling solution containing 30% salt and 3% sodium hydroxide at 20±3°C for 3 days; and fresh eggs and pickling solution The mass ratio is 3-3.5:5.

[0044] (2) Preheat the marinated eggs in 88°C water for 2 minutes, then boil them in 115°C salt water with a mass concentration of 28% for 4 minutes, then wash the surface salt in 60°C warm water and cooled to 85°C on the surface of the eggshell;

[0045] (3) After washing the surface salt and drying the eggs with a temperature higher than 80 °C, immerse them in nano-Ag@SiO at a temperature of 85 °C. 2 The modified PVA coating solution is taken out and air-dried to form a complete coating film, which is then made into a coated film packaged soft-boiled breakfast egg.

[0046] Nano Ag@SiO 2 The preparation of modified PVA coating solution is as in case 1

[0047] Table 3 The quality characteristic index of embodiment 3 soft-boiled breakfast eggs:

[0048]

[0049]

[0050] Pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com