A black-and-white two-color thermal insulation and anti-aging six-type greenhouse film and its preparation method

A greenhouse film, anti-aging technology, applied in chemical instruments and methods, botanical equipment and methods, greenhouse cultivation, etc., can solve problems such as fish eyes, local quality decline, cost increase, etc. The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

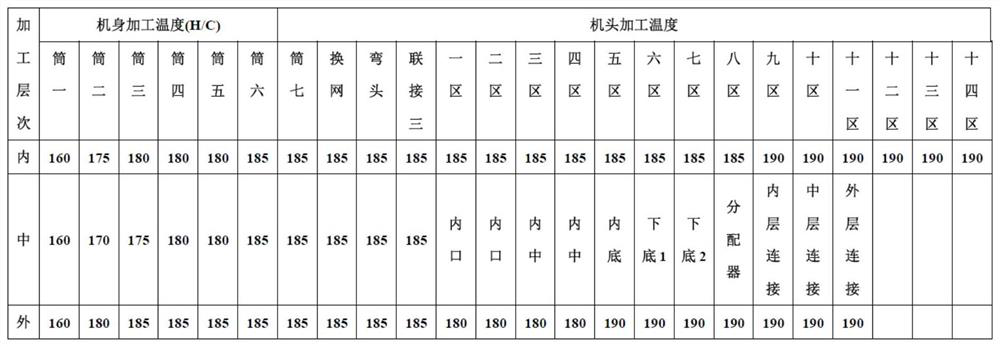

[0071] In a specific embodiment, the preparation method of the black-and-white double-color heat preservation and anti-aging six-type greenhouse film includes the following steps:

[0072] 1) Preparation of raw materials for each layer of film

[0073] Mix the raw materials of the inner layer, middle layer and outer layer, and send them to the first, second and third twin-screw extruders for mixing respectively, the rotation speed of the screws is 40-100 rpm, and the extrusion processing pressure is 30-50 MPa;

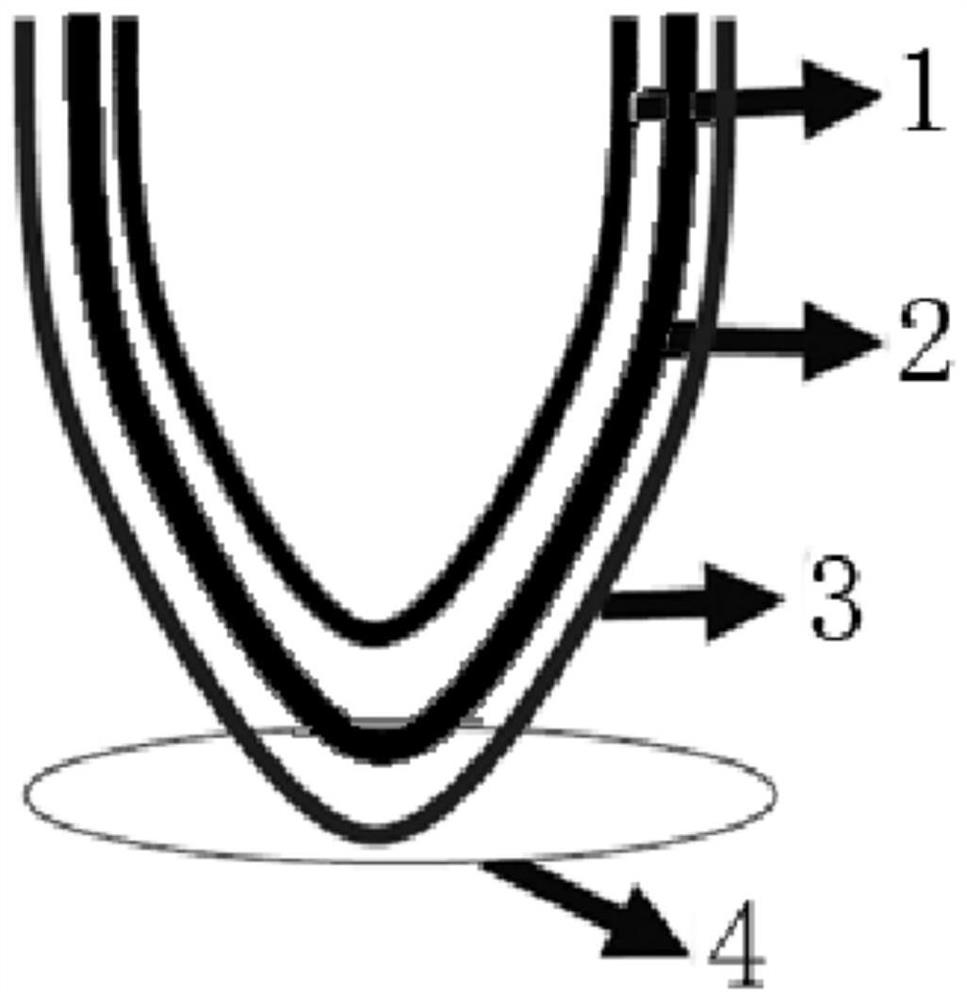

[0074] 2) Extrusion molding

[0075] Using three-layer co-extrusion compound calendering process, the product is obtained through heating, extrusion, blow molding, upper traction, lower traction and winding into film.

[0076] In a preferred embodiment, the preparation method of the black-and-white double-color thermal insulation and anti-aging six-type greenhouse film comprises the following steps:

[0077] 1) Preparation of raw materials for each layer of film

[...

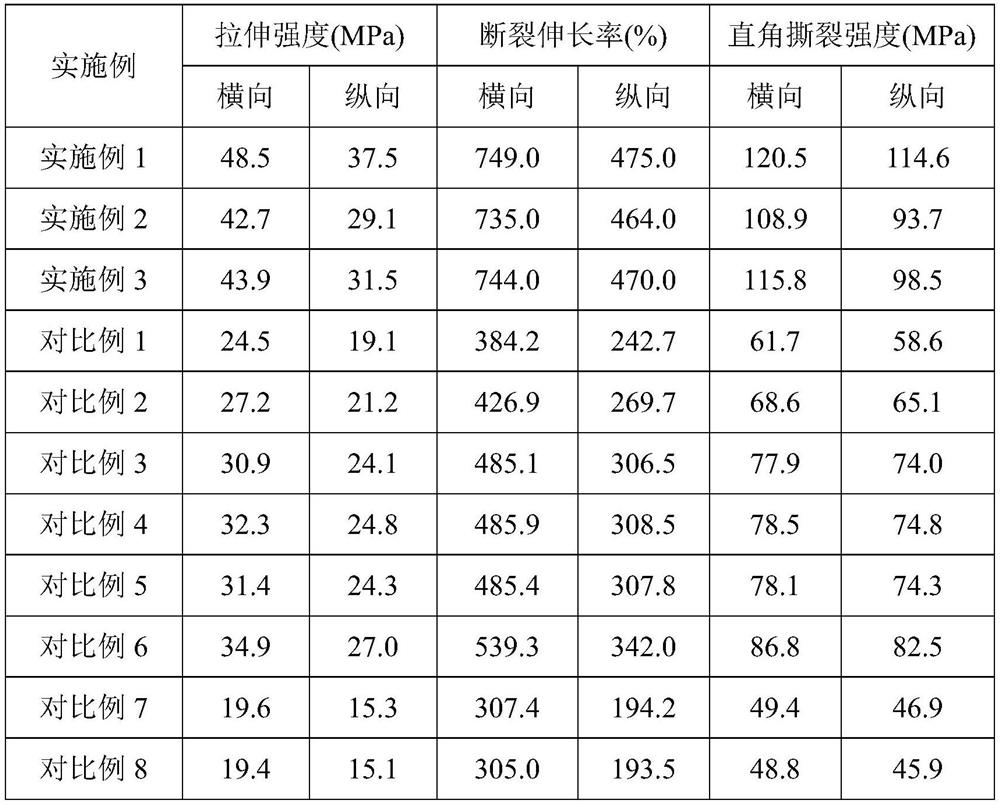

Embodiment 1

[0091] The first aspect of Example 1 provides a black-and-white double-color thermal insulation and anti-aging six-type greenhouse film.

[0092] The black-and-white two-color thermal insulation and anti-aging six-type greenhouse film comprises an inner layer, a middle layer and an outer layer; the thickness ratio of the inner layer, the middle layer and the outer layer is 3:4:3;

[0093] The inner layer consists of the following components by weight:

[0094] 500 parts of mLLDPE, 50 parts of longevity masterbatch, 15 parts of black masterbatch;

[0095] The middle layer consists of the following components by weight:

[0096] 400 parts of LDPE, 100 parts of EVA, 50 parts of longevity masterbatch, 40 parts of white masterbatch;

[0097] The outer layer consists of the following components by weight:

[0098] 200 parts of LLDPE, 300 parts of mLLDPE, 50 parts of longevity masterbatch, 25 parts of white masterbatch.

[0099] The second aspect of Example 1 provides a method fo...

Embodiment 2

[0111] The first aspect of Example 2 provides a black-and-white double-color thermal insulation and anti-aging six-type greenhouse film.

[0112] The black-and-white two-color thermal insulation and anti-aging six-type greenhouse film comprises an inner layer, a middle layer and an outer layer; the thickness ratio of the inner layer, the middle layer and the outer layer is 3:4:3;

[0113] The inner layer consists of the following components by weight:

[0114] 400 parts of mLLDPE, 40 parts of longevity masterbatch, 12 parts of black masterbatch;

[0115] The middle layer consists of the following components by weight:

[0116] 300 parts of LDPE, 75 parts of EVA, 37.5 parts of longevity masterbatch, 30 parts of white masterbatch;

[0117] The outer layer consists of the following components by weight:

[0118] 100 parts of LLDPE, 150 parts of mLLDPE, 25 parts of longevity masterbatch, 12.5 parts of white masterbatch.

[0119] The second aspect of Example 2 provides a method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com