Saturable absorber preparation method and reflective and transmissive saturable absorber

A saturable absorption and system technology, used in laser parts, electrical components, lasers, etc., can solve the problems of complex preparation process, short working life and high production cost, and achieve simple preparation process, long working life and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

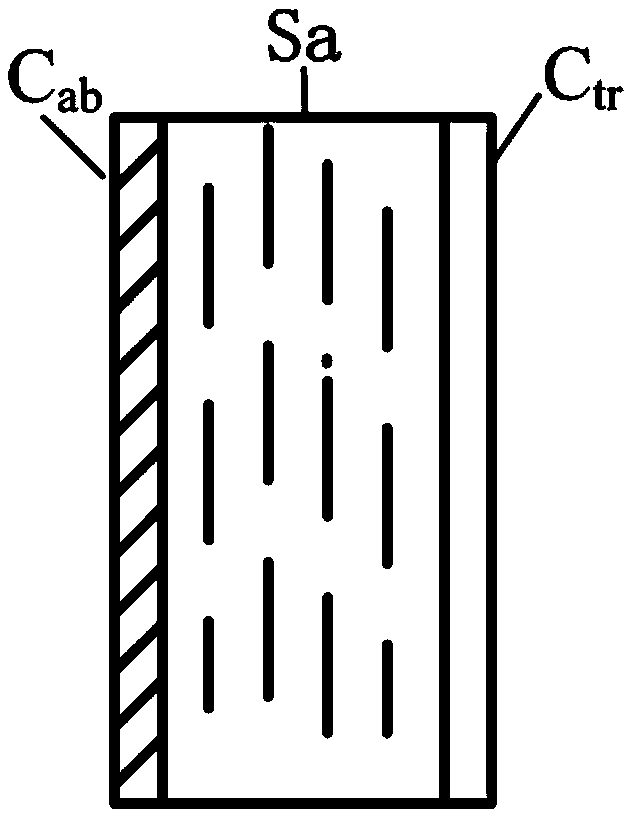

[0033] see figure 1 , this embodiment provides a method for preparing a saturable absorber, comprising the following steps:

[0034] 1) Disperse the graphene in the dispersion liquid, the dispersion liquid is a mixture of alcohol and water; then use an ultrasonic machine with a power of 1000W to sonicate for two hours, so that the material can be fully peeled off and dispersed evenly; the dispersion of two-dimensional nanomaterials is obtained Liquid, namely graphene dispersion liquid;

[0035] 2) Soak the single-layer or few-layer porous glass with silica as the skeleton in the graphene dispersion, and carry out the screening and adsorption process under ultrasonic conditions. The size of the porous glass is 5cm×3cm×0.6cm, and the pore size is the same , are all about 20nm (the size of the saturable absorber is not limited by the preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com