Water pump built-in comprehensive detection component and its usage method

A comprehensive detection and component technology, applied in pump control, measuring devices, non-variable pumps, etc., can solve problems such as large rotation resistance of submersible pump motor rotor, misjudgment of pump working status, inaccurate water level detection, etc., to achieve components The effect of reduction, simplicity of use, and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention will be described in detail below in conjunction with the accompanying drawings.

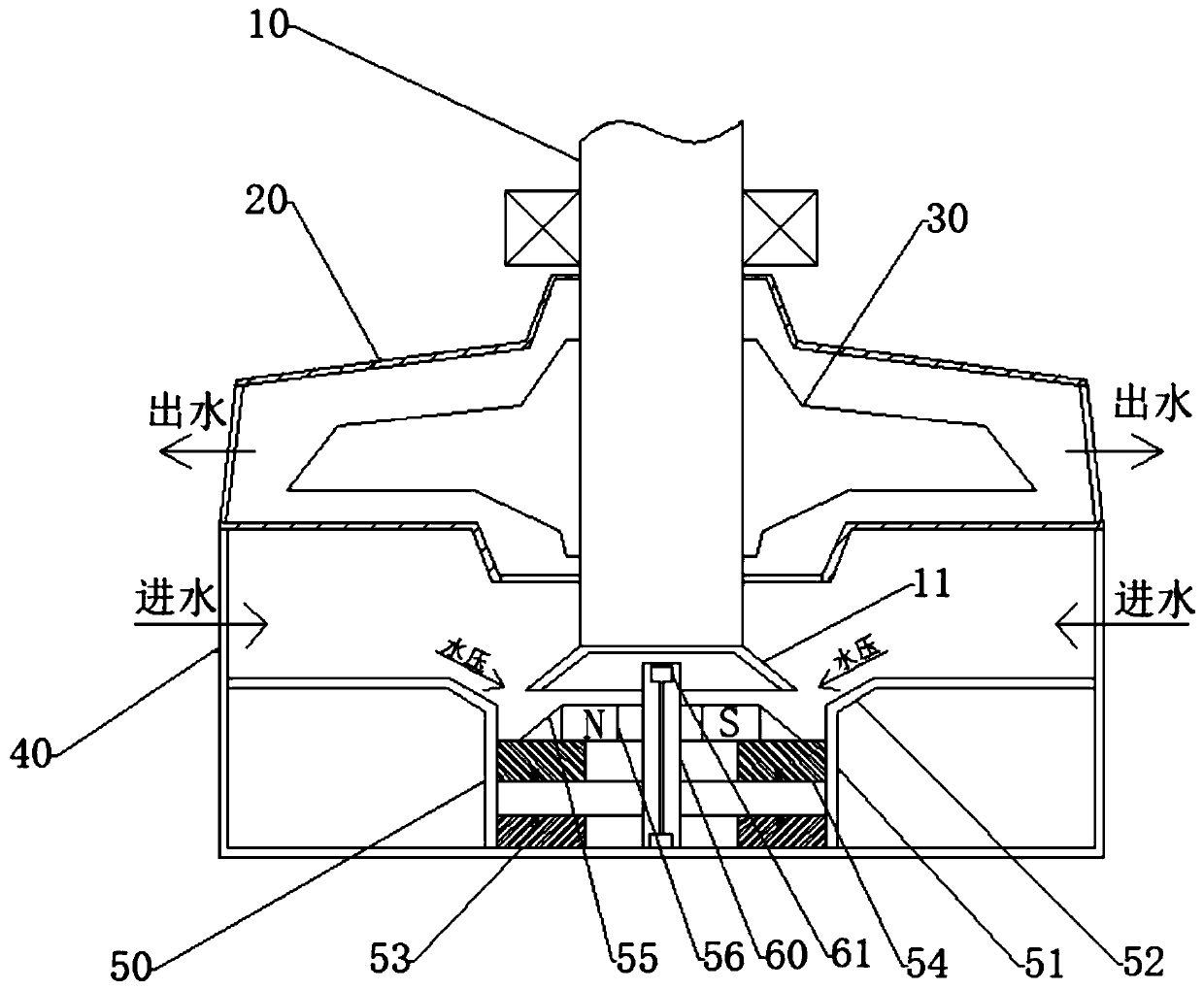

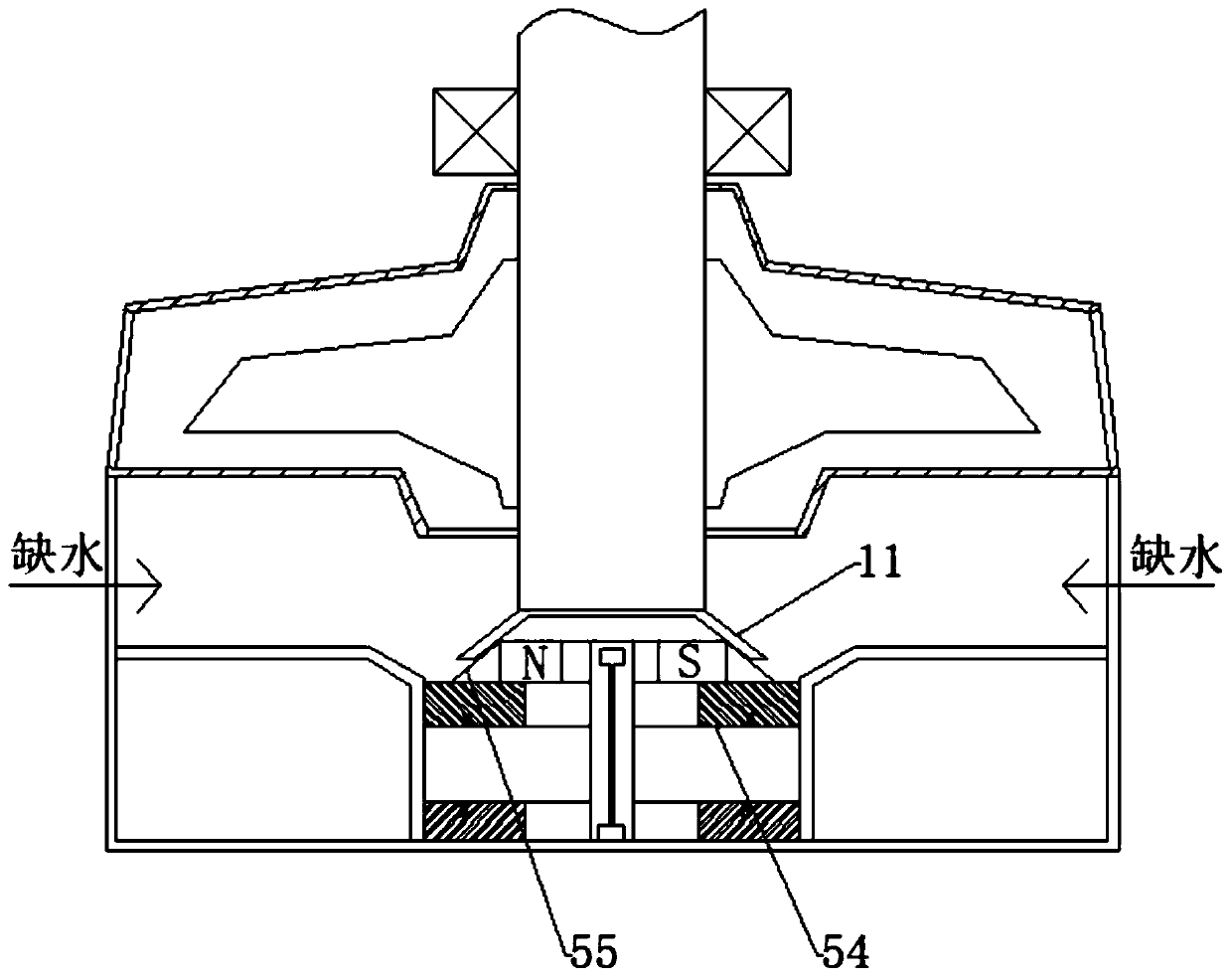

[0038] Such as Figure 1-3 As shown, a water pump control system includes a casing, a motor, and a water pump impeller 30 . The rotating shaft 10 of the motor is arranged vertically, and the water pump impeller 30 is set at the bottom. The bottom end of rotating shaft 10 stretches in the water inlet chamber 40, and a cone-shaped clutch ring 11 is fixed at its spare end.

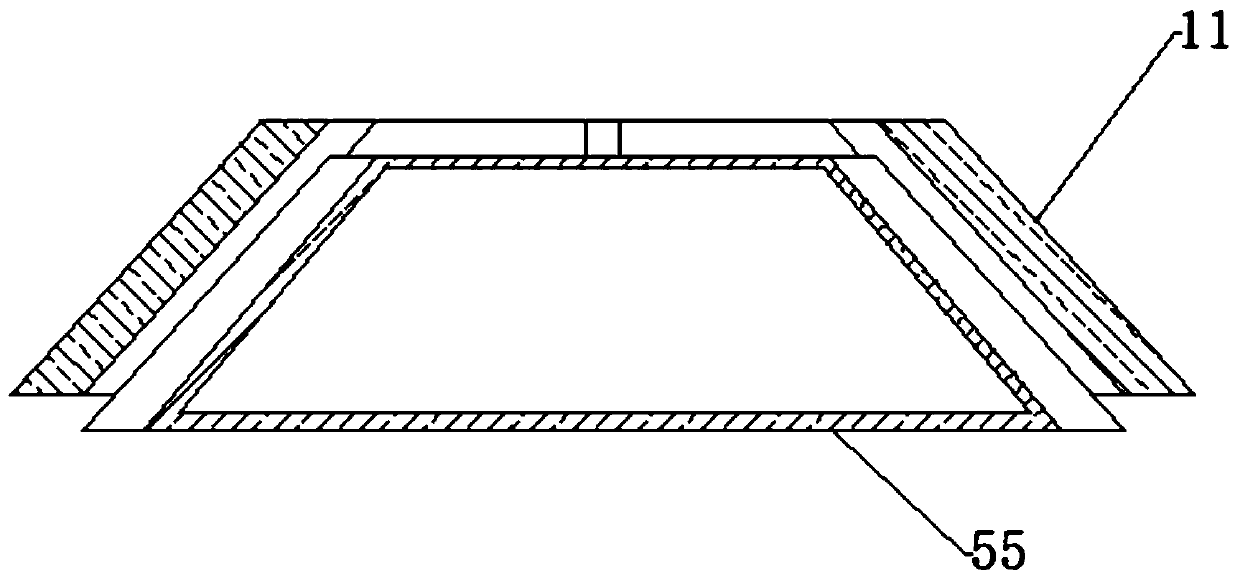

[0039] A drainage ring 50 is fixed on the inner bottom of the water inlet chamber 40 . The drainage ring 50 includes a cylindrical barrel 51 , an inverted cone ring 52 and a plane ring. The cylindrical barrel 51 is coaxial with the rotating shaft 10 . The cylindrical tube 51 is coaxial with the inverted cone ring 52, and its top edge is sealed and fixed with the bottom edge of the inverted cone ring 52. The face seal is fixed.

[0040] A ring magnet 53 is fixed at the inner bottom of the cylindrical bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com