Multi-opening multi-pipe-section large-section tunnel, construction method, pipe section connection structure and connection method

A connection method and connection structure technology, which are used in the connection of large-section tunnels, the construction of multi-opening and multi-section large-section tunnels, the joint connection structure of large-section tunnels, and the multi-opening and multi-section large-section tunnels. ,In the field of tunnel pipe joint connection, it can solve the problems of complex underground space construction environment (the impact of surrounding roads, underground pipelines, structures, etc.), and achieve the effect of low cost, high construction efficiency and large inner diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

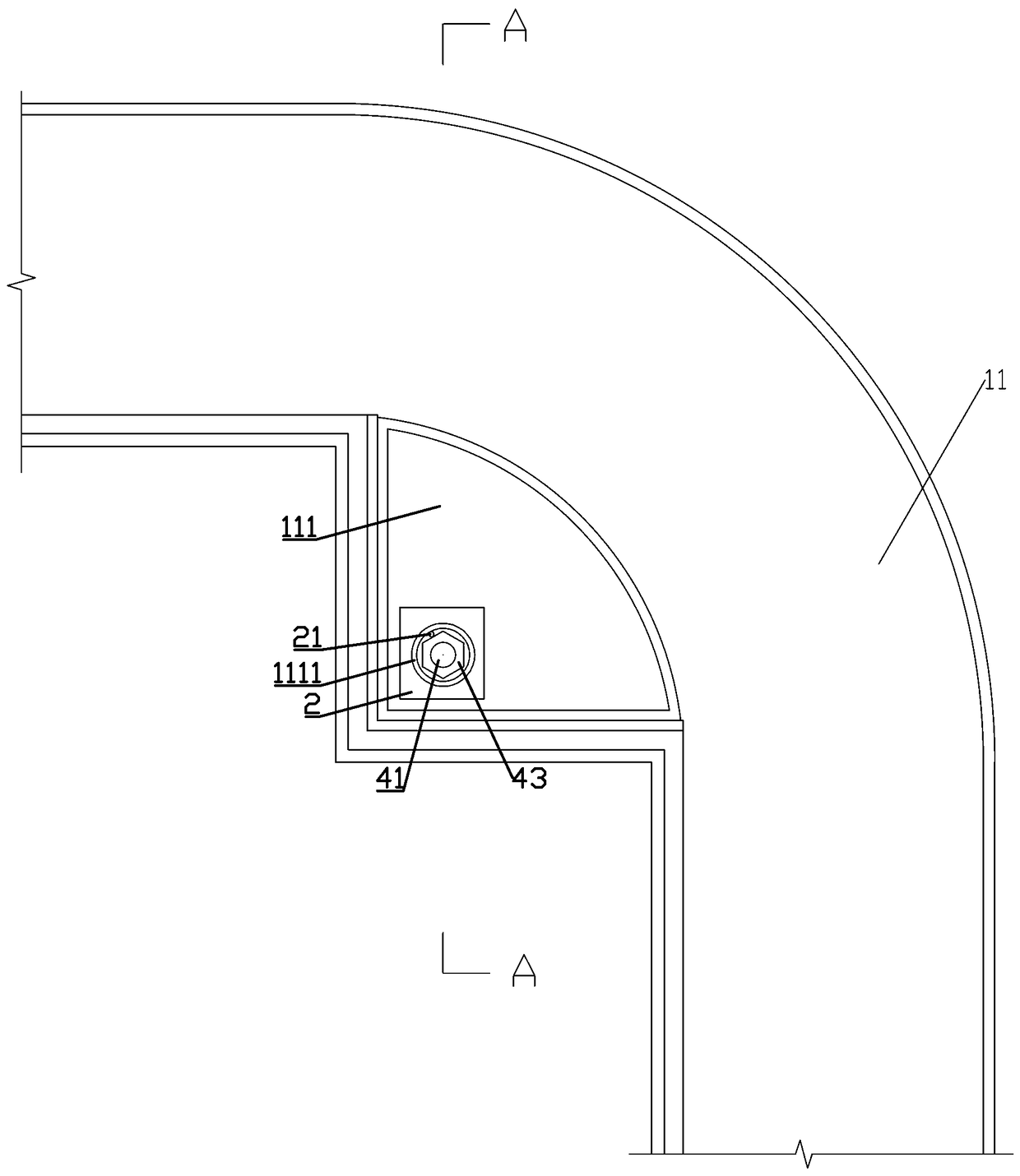

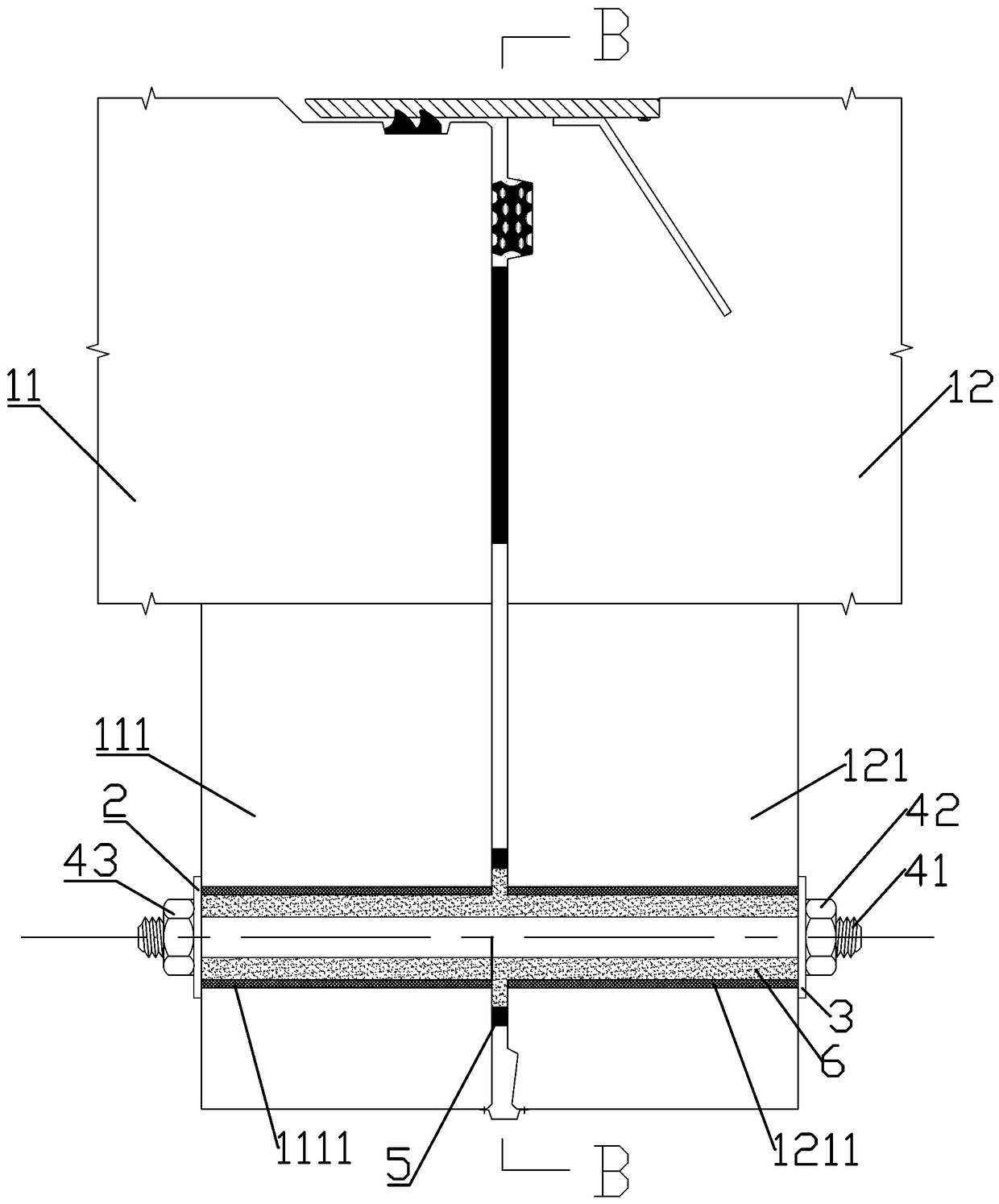

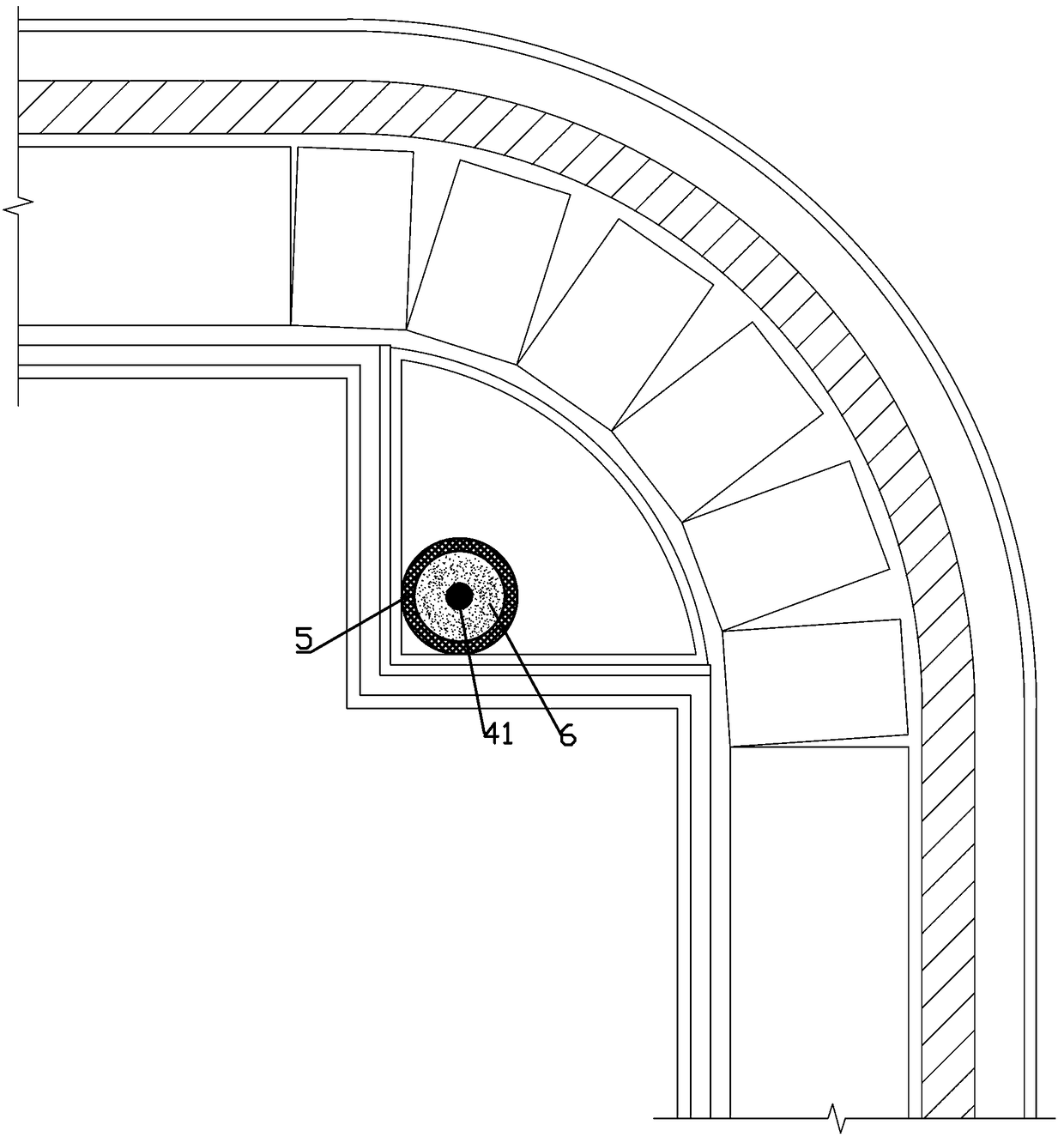

[0043] Embodiment 1: A pipe joint connection structure for a large-section tunnel of the pipe jacking construction method, see Figure 1-3 , including at least two pipe joints, connecting parts, pads 2, pads 3 and elastic waterstop rings 5 arranged adjacent to each other longitudinally along the tunnel direction.

[0044] On the upper part of both sides of the inner wall of the pipe joint (including the top of the inner wall and the upper part of the side wall of the inner wall), there are respectively tensioning parts. The two tensioning parts are preferably symmetrical with the stress centered plane of the complete pipe joint as the symmetrical plane. For setting, a tension hole is provided in the tension part, and the tension hole is also preferably arranged symmetrically with the force-bearing center plane of the complete pipe joint as the symmetrical plane. In this way, the side wall of the tube section under the tensioned corner can be opened on one side, which can sol...

Embodiment 2

[0053] Embodiment 2: A method for connecting pipe joints used in the pipe jacking construction method, comprising the following steps: obtaining pipe joints for large-section tunnels; The upper part of the side wall) are respectively provided with tensioning parts. The two tensioning parts are preferably arranged symmetrically with the centered surface of the complete pipe joint as the symmetric plane. Tensioning holes are provided in the tensioning parts. The pulling holes are also preferably arranged symmetrically with the stress-bearing center plane of the complete pipe joint as the symmetrical plane; the pipe joints for the large-section tunnel are arranged longitudinally along the tunnel direction by the pipe jacking construction method, and the two ends that need to be connected into a whole The pipe joints are respectively pipe joint 11 and pipe joint 12, that is to say, there can be 1 pipe joint, 2 pipe joints or multiple pipe joints between the pipe joint 11 and the pi...

Embodiment 3

[0062] Embodiment 3: A construction method for constructing a multi-opening multi-pipe-section type large-section tunnel using the pipe-joint connection method for the large-section tunnel of the pipe jacking construction method in Embodiment 2, comprising the following steps:

[0063] Obtain the pipe joints used to form large-section tunnels, and use the pipe jacking construction method to construct multi-pipe-section large-section tunnels;

[0064] Adopting the pipe joint connection method of the large-section tunnel used in the pipe jacking construction method in Embodiment 2 will correspond to the pipe joints at the side openings and the pipe joints adjacent to the side openings, and other load-bearing requirements of large-section tunnels. The tensile parts on both sides of the pipe joints that need to be connected are connected and fixed together according to the settlement amplitude requirements;

[0065] A side outlet is constructed on the side of the side opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com