Assembled swimming pool and installation method

An installation method and assembled technology, which is applied in the direction of swimming pools, pipe supports, pipes/pipe joints/fittings, etc., can solve the problems of consuming a lot of manpower and material resources, and the construction time of swimming pools is long, so as to achieve simple installation methods and significant site adaptability , the effect of uniform load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

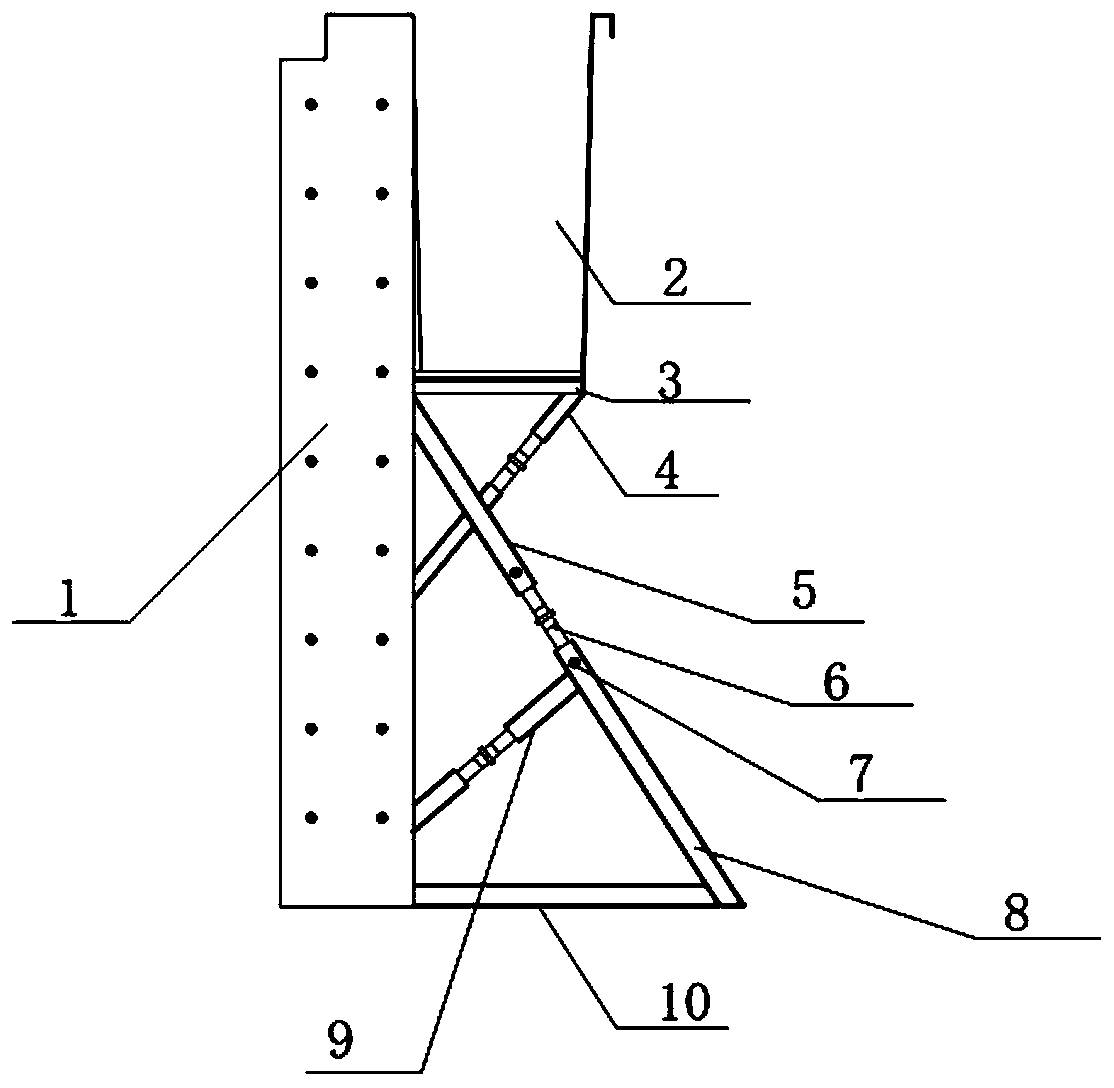

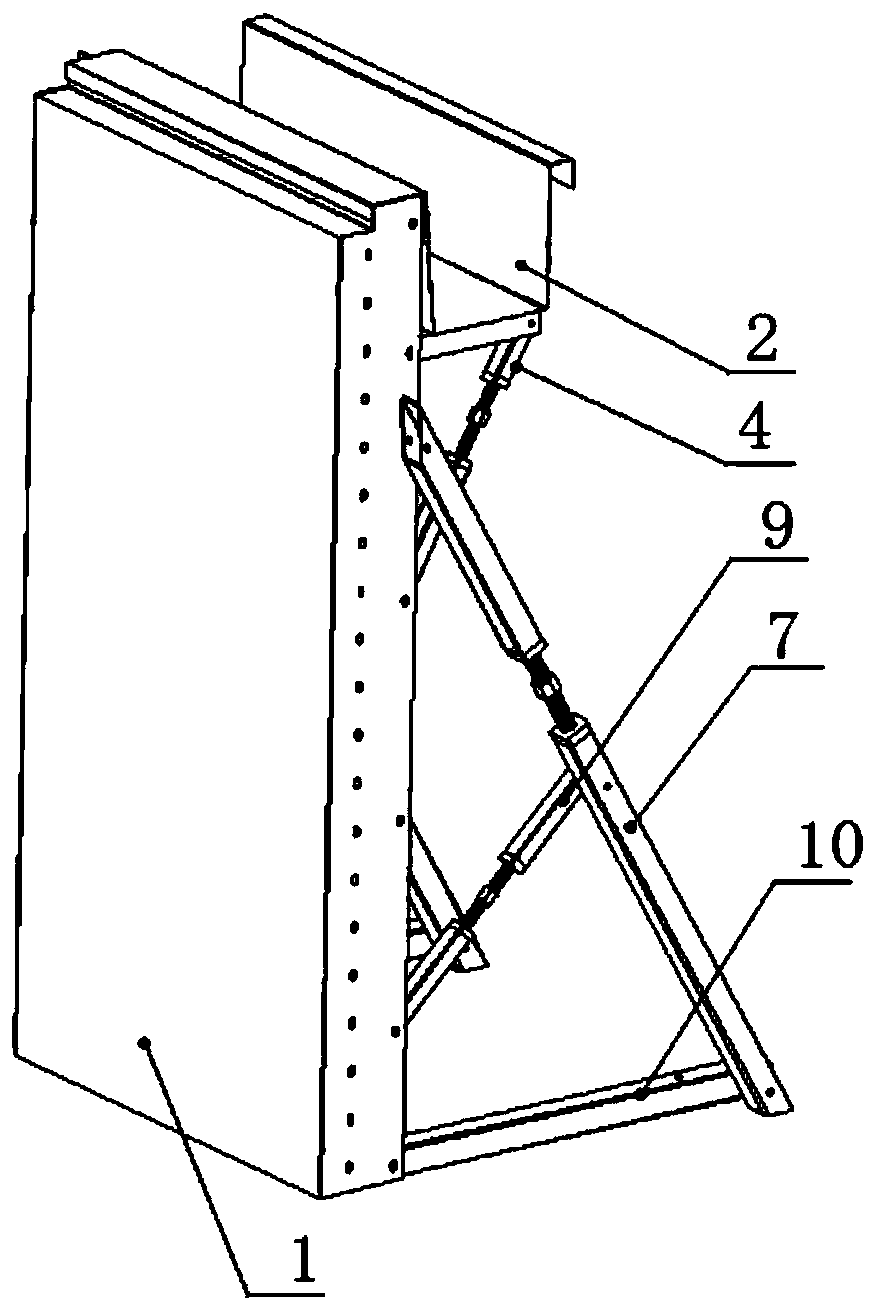

[0075] The anchor tube 6 is provided with a plurality of threaded holes, and the screw 7 is matched with different threaded holes on the anchor tube 6 to change the length of the anchor tube 6 sleeved in the first anchor sleeve 5 and the second anchor sleeve 8 to further realize Adjustments to the length of the long support frame.

[0076] The threaded hole is arranged perpendicular to the main body of the anchor pipe 6 , that is, the threaded hole is perpendicular to the axial direction of the anchor pipe 6 .

example 2

[0078] The anchor pipe 6 adopts a columnar steel structure with external threads at both ends, and the two ends of the anchor pipe 6 are respectively fixed with the first anchor sleeve 5 and the second anchor sleeve 8 through screw connections. Correspondingly, the first anchoring sleeve 5 and the second anchoring sleeve 8 are provided with internal threads matching the external threads at both ends of the anchoring pipe 6 .

[0079] Specifically, the external threads at both ends of the anchoring tube 6 have the opposite direction of rotation. When the anchoring tube 6 is rotated, the two ends of the anchoring tube 6 are screwed out or screwed into the first anchoring sleeve 5 and the second anchoring sleeve 8 respectively, and then , the length of the anchor pipe 6 connected to the long support frame becomes longer or shorter. For example: when the anchor tube 6 is set to rotate clockwise relative to the first anchor sleeve 5 and the second anchor sleeve 8, both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com