Making technology of clothing decorative patch, clothing decorative patch and clothing

A technology for making crafts and decorative stickers, applied in the field of embroidery, can solve the problems of difficult to meet the requirements of functions, single decorative style, affecting product quality, etc., to achieve the effect of soft light, easy to use, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

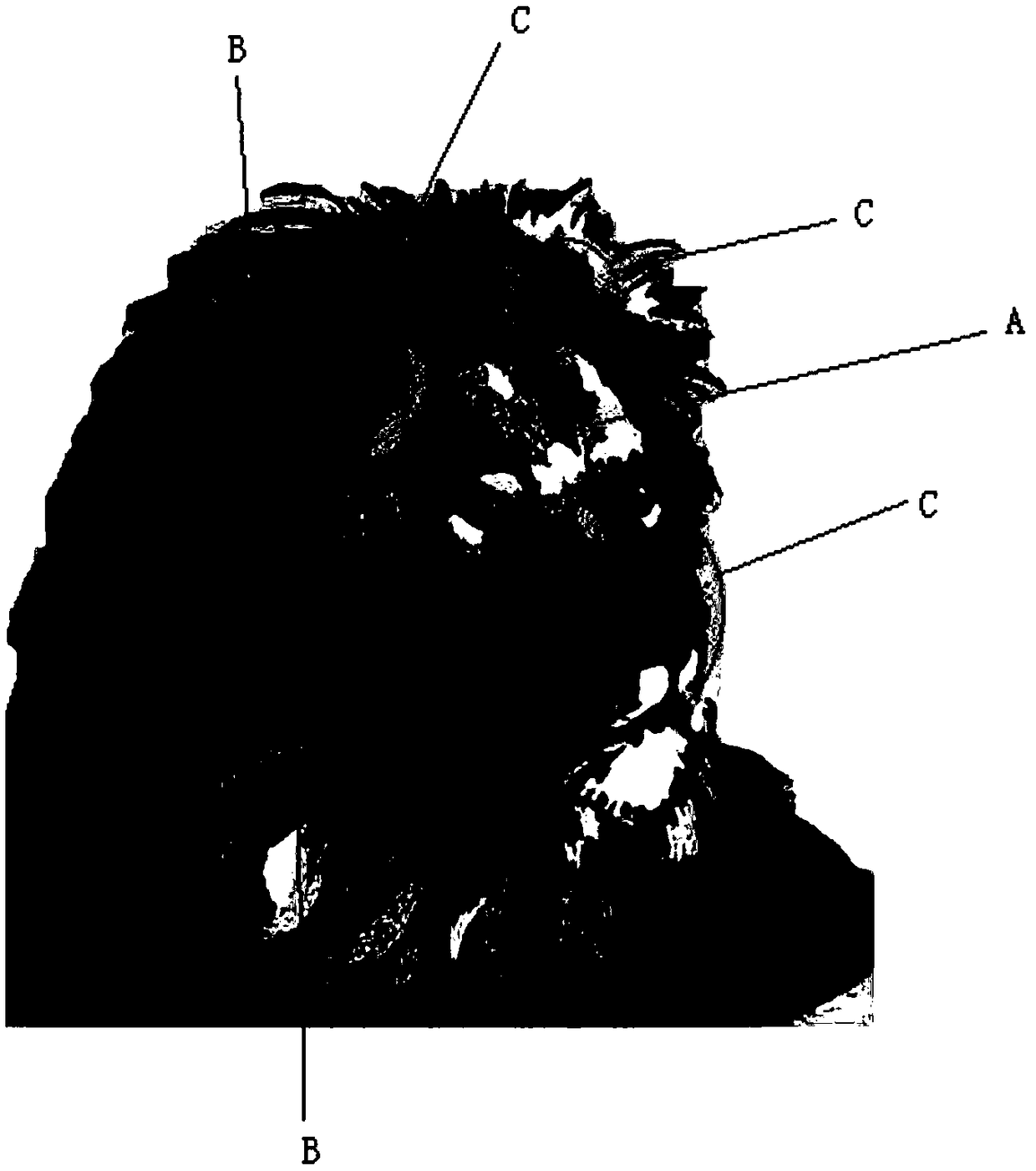

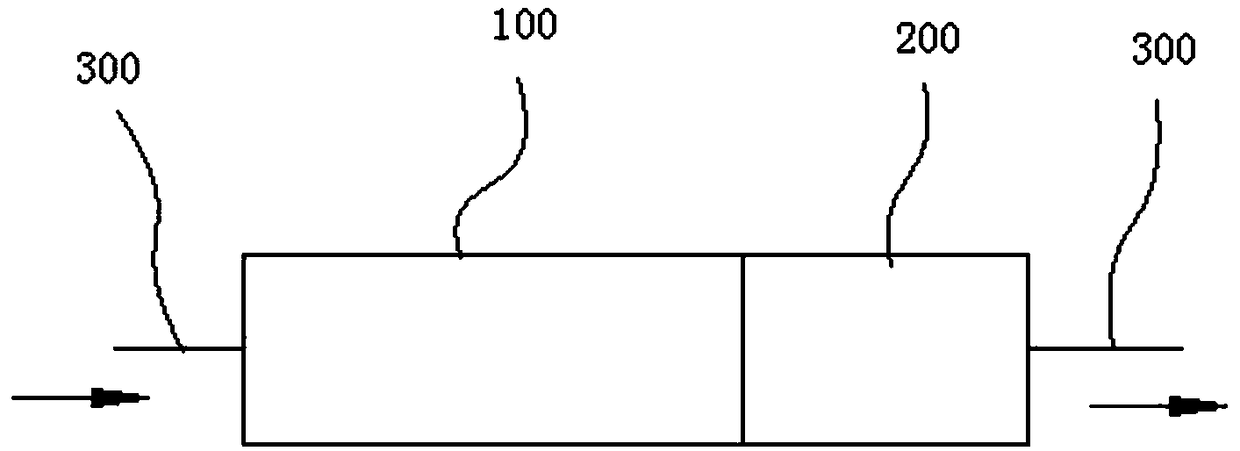

[0039] The invention provides a manufacturing process of a clothing decorative sticker, which includes a plane embroidery process, a tufting process and a 3D printing process. see figure 1 , figure 1 It is an effect drawing of the production process of the clothing decorative sticker of the present invention. figure 1 The face A of the middle lion adopts the plane embroidery process, the neck part B of the lion adopts the tufting process, and the lion's nose and ear parts C use the 3D three-dimensional printing process. Combine below figure 1 The manufacturing process of the garment decorative sticker of the present invention is described.

[0040] The manufacturing process includes:

[0041] S1. Select the fabric to be processed as the base fabric, sizing on the back of the base fabric, drying and ironing, and set aside. In another embodiment, a layer of non-woven fabric can also be attached to the selected base fabric for use, so as to increase the stability of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com