Shaft beating device for doubling of polyester yarns

A shaft device and yarn technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of not being able to create profits and high-quality products, not being able to be used in a reasonable combination, and being inconvenient for operators, etc. Achieve the effects of preventing winding, convenient operation and ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

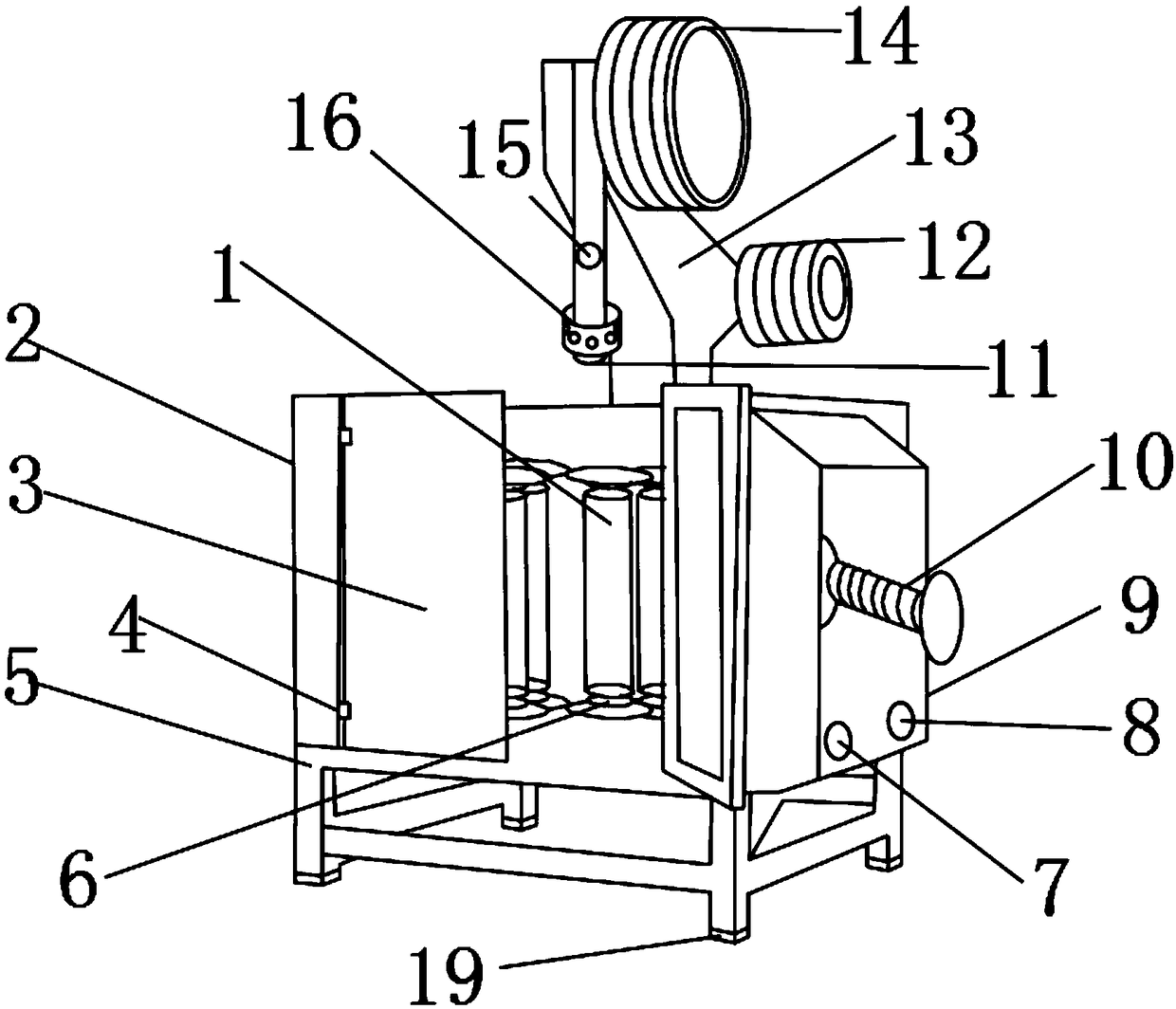

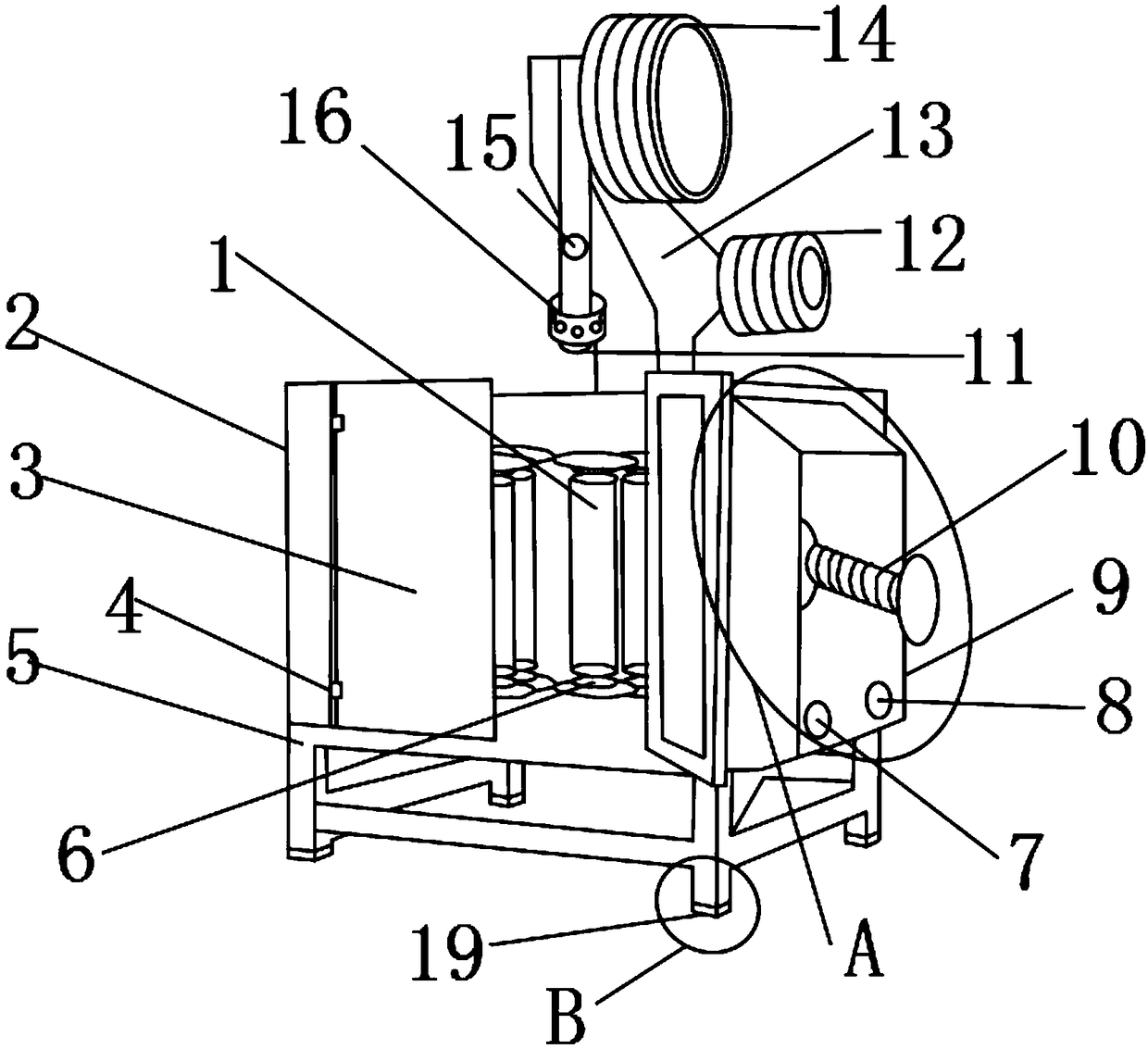

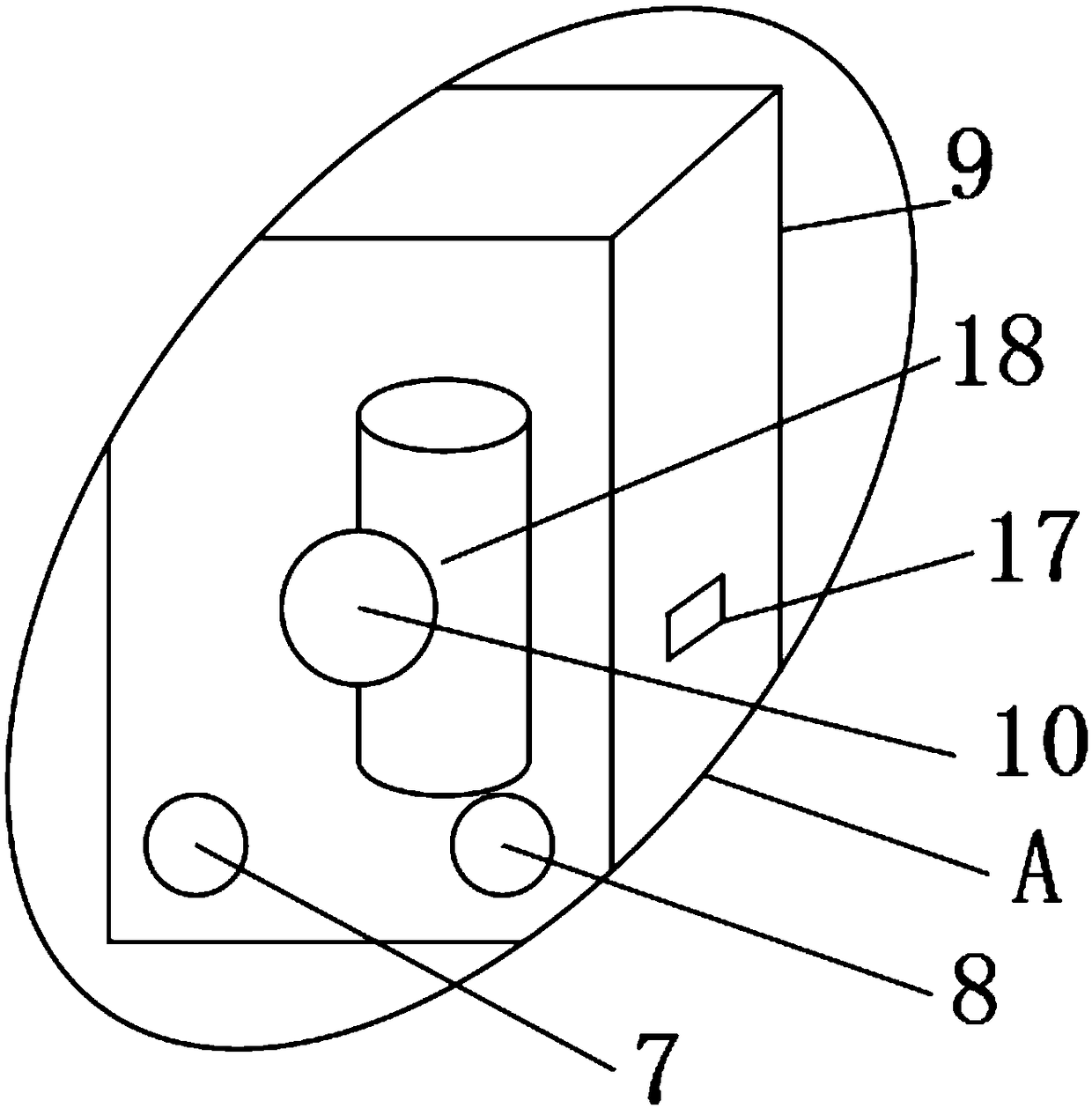

[0018] Such as Figure 1-4 As shown, a shafting device for doubling polyester yarns includes an equipment main body 2 and a motor cabinet 9, the outer surface of the equipment main body 2 is provided with an equipment hatch 3 and a connecting buckle 4, and the lower end of the equipment main body 2 is provided with There is a support base 5, and the inside of the equipment main body 2 is provided with a bobbin sleeve rod 1, and both ends of the wire bobbin sleeve rod 1 are provided with a No. 1 rotating shaft 6, and the upper end of the equipment main body 2 has a bracket 13, and the bracket One side of 13 is provided with No. 1 frosted threaded wheel 12, and the other side of support 13 is provided with No. 2 frosted threaded wheel 14, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com