Detachment device

A technology of peeling device and protective film, which is used in transportation and packaging, thin material processing, electrical components, etc., can solve the problems of insufficient amount of adhesive and inability to have adhesive force, and achieve the effect of true peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

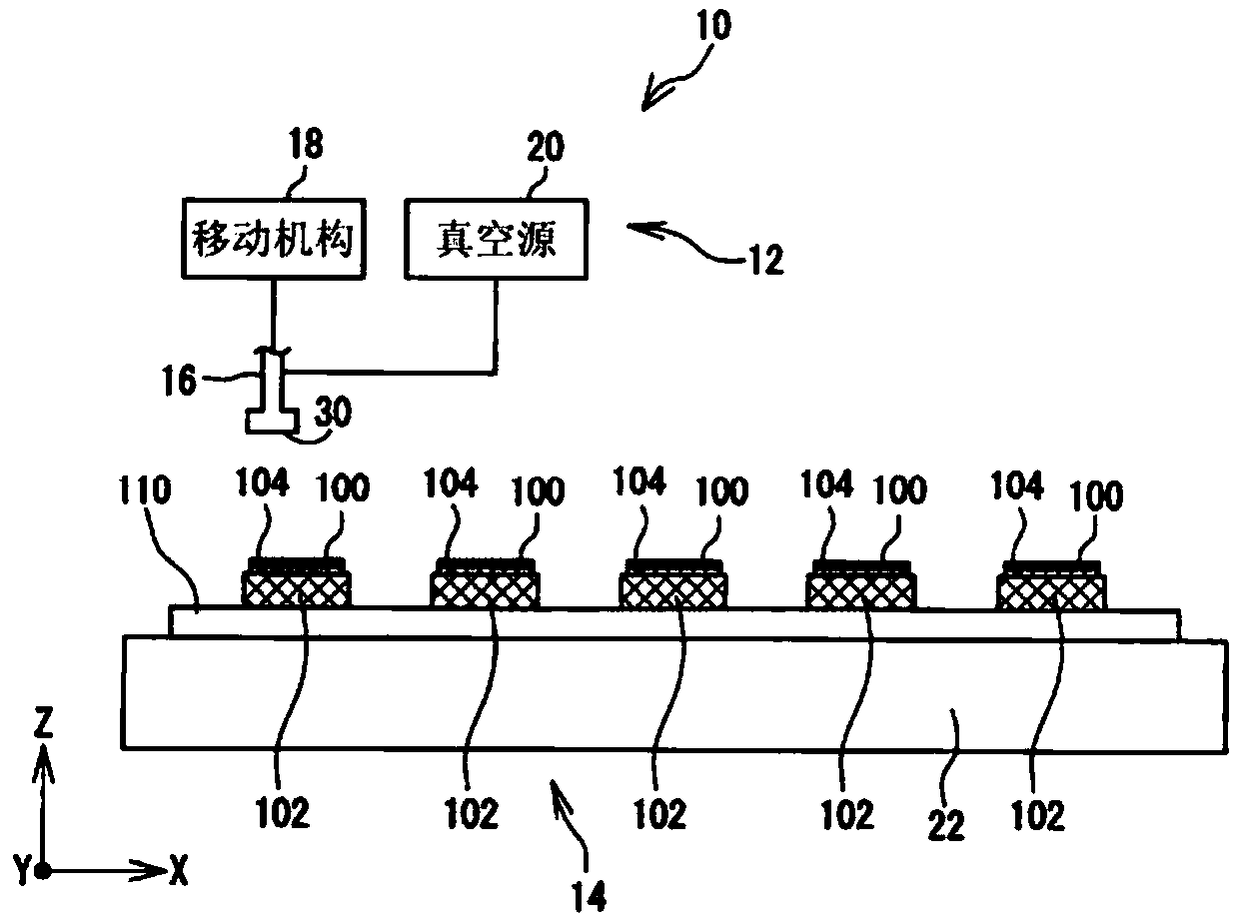

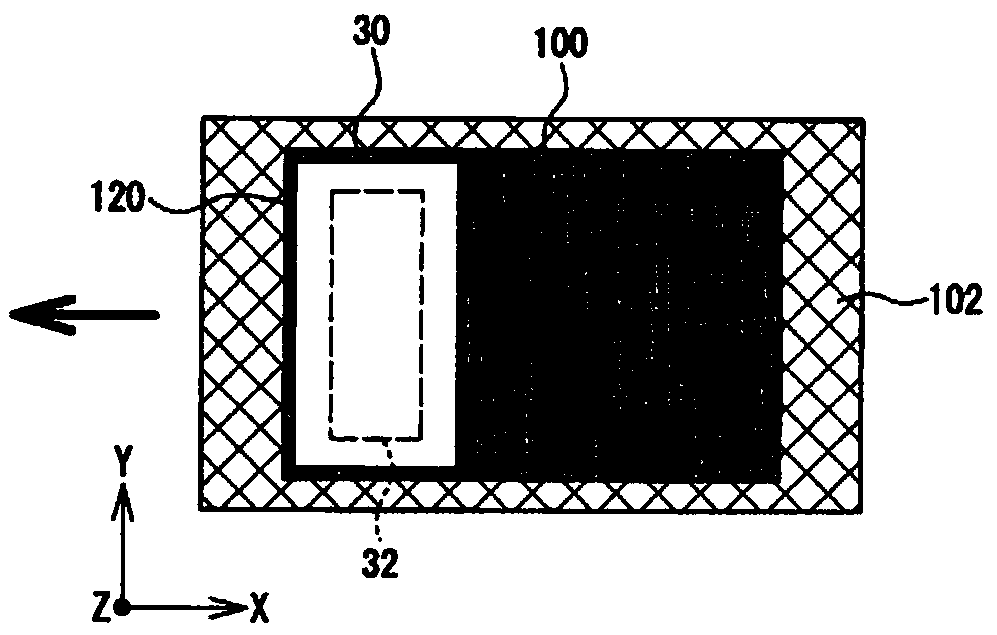

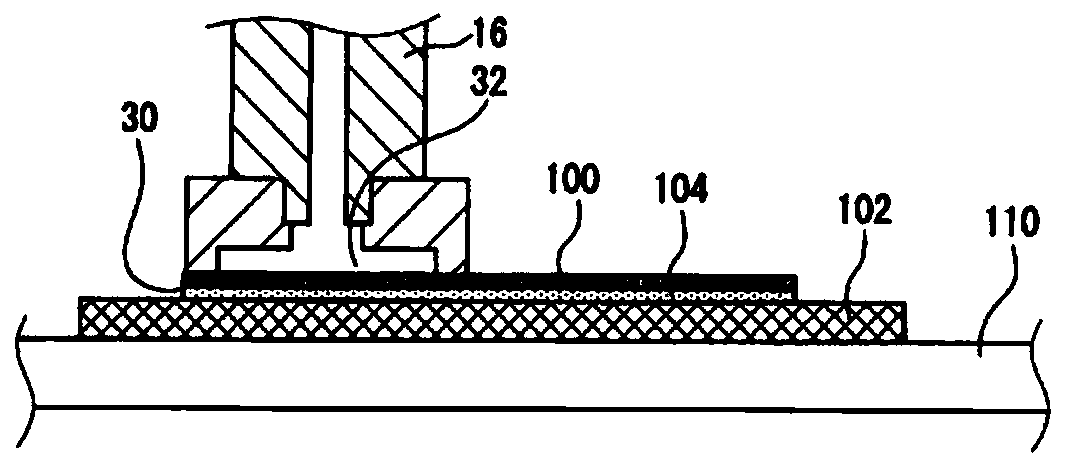

[0029] Hereinafter, the structure of the peeling device will be described with reference to the drawings. figure 1 It is a schematic structural diagram of the peeling apparatus 10 of a protective film. figure 2 It is a schematic diagram showing the shapes of the collet 16 and the workpiece 102 . and, image 3 It is a side view showing the peeling state of the protective film 100, Figure 4 yes image 3 A partial enlargement of the .

[0030] The peeling device 10 is a device that peels the protective film 100 from the adhesive member (DAF 104 ) attached to the workpiece 102 . The workpiece 102 is, for example, a semiconductor chip mounted on a substrate 110 . On the surface of the workpiece 102, a DAF 104 is adhered as an adhesive member. The DAF 104 is a film having a function as a die attach agent (adhesive) as is well known, and the DAF 104 is heated and hardened to bond the semiconductor chip. Typically, such a DAF 104 is laminated on the backside of a semiconducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com