Covering stripping device for covered electric cable

A technology for covering wires and coating layers, which is applied in the direction of line/collector parts, circuits, electrical components, etc., and can solve problems such as broken wires, scratches from wire coating strippers, and uncoated wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

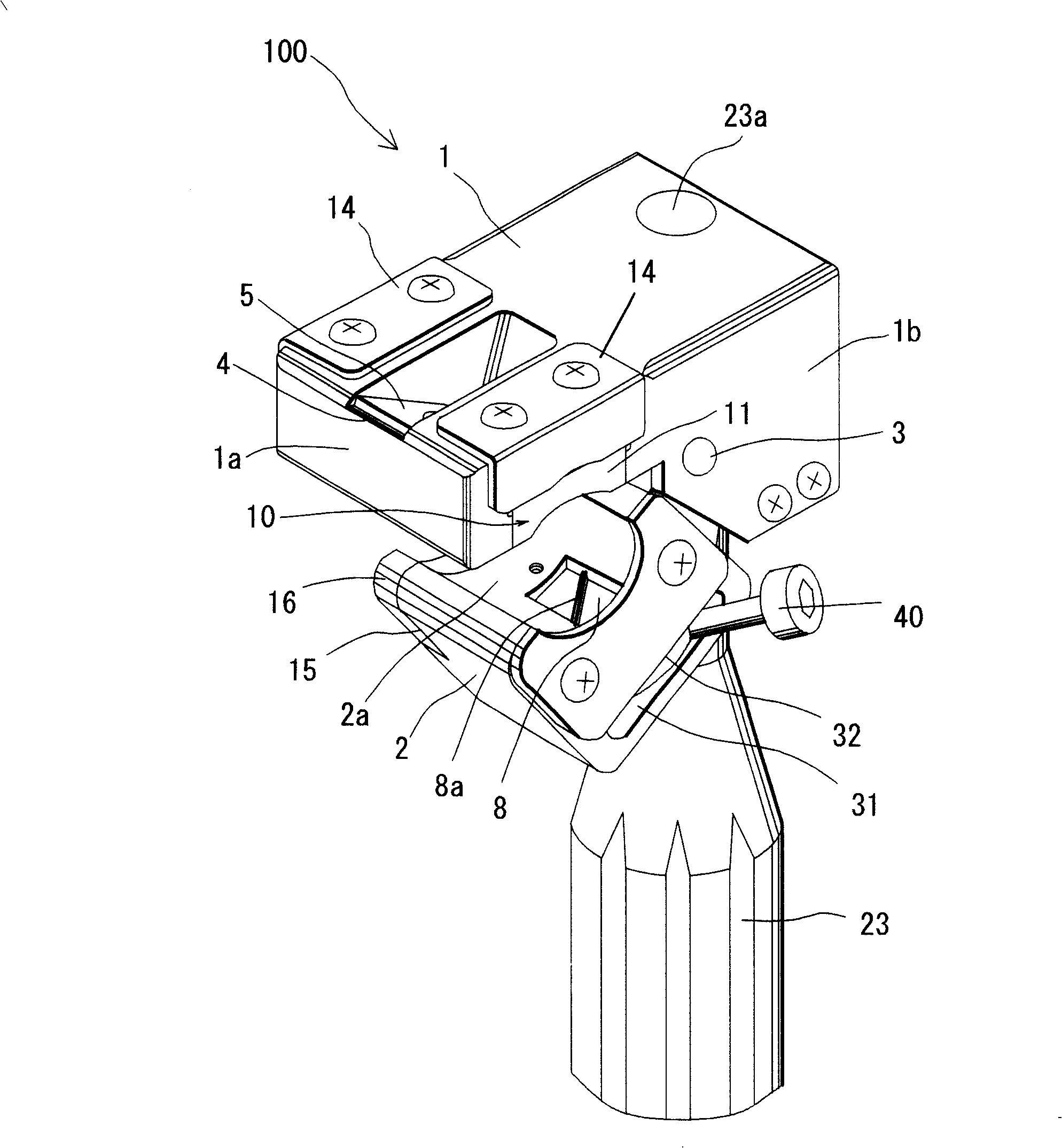

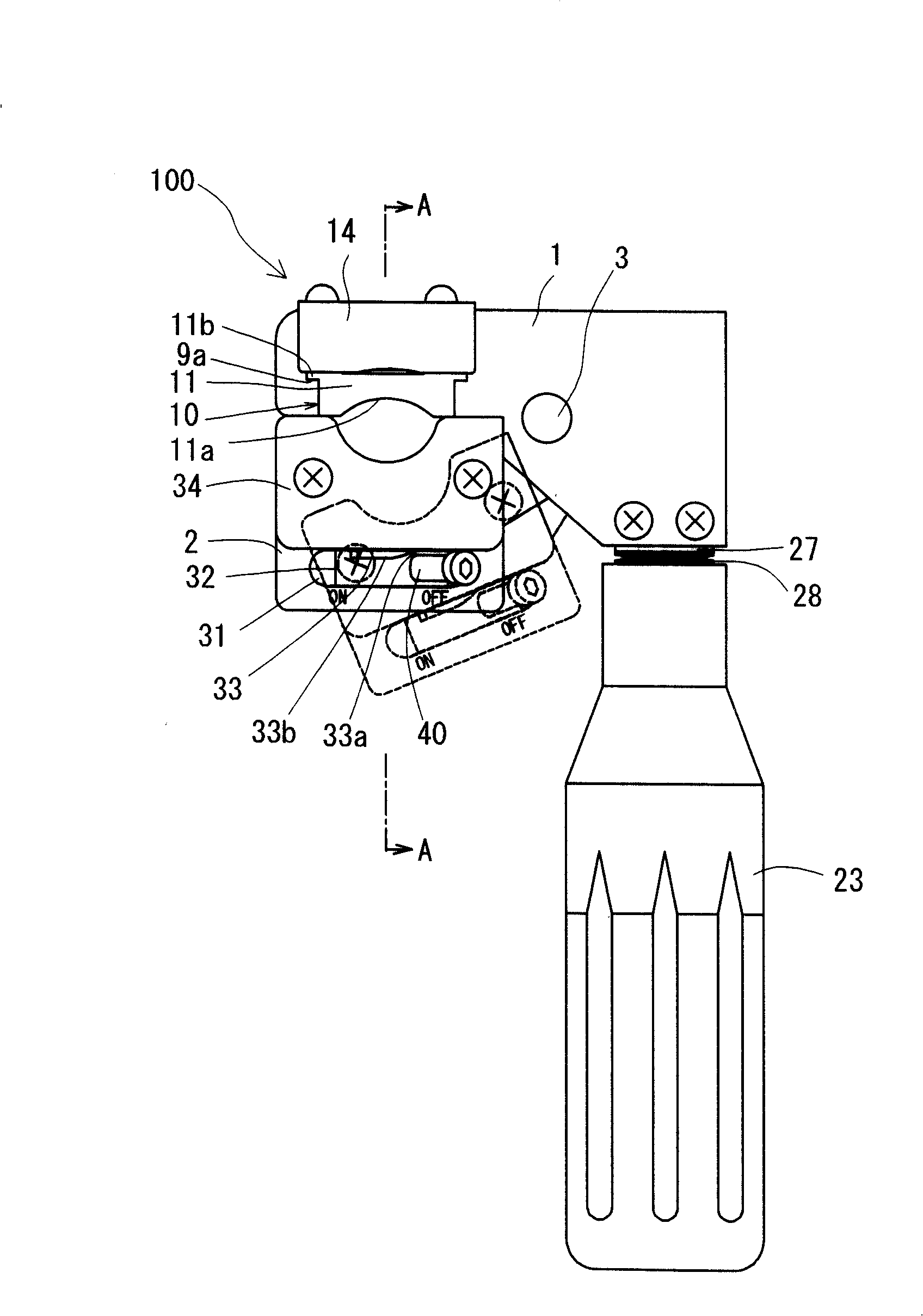

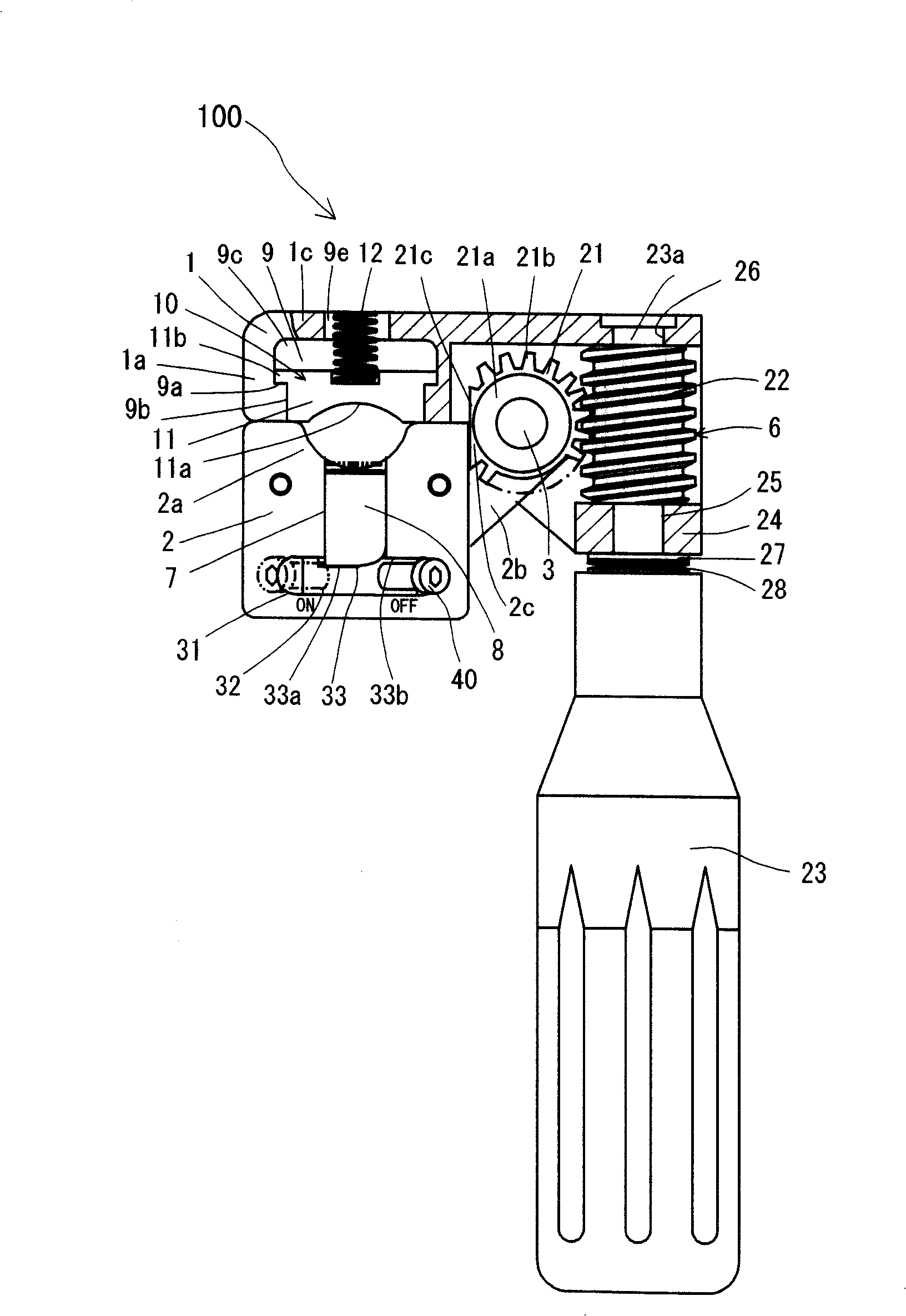

[0037]Covered electric wire coating stripper 100 of the present invention comprises: clamping part body 1, has one side clamping part 1a that clamps covered electric wire D; The clamping part 1a jointly clamps the other side clamping part 2a of the coated wire, and is supported on the clamping part body 1 in a freely rotatable manner through the shaft, and at the same time, the other side clamping part 2a can approach or leave the clamp. Rotate in the direction of the one side clamping portion 1a of the clamping component body 1; the cutter 5 for peeling off the cladding layer is arranged at the near center of the one side clamping portion 1a of the clamping component body 1; the operating mechanism 6 is used to rotate The movable clamping member 2 rotates relative to the covered electric wire D in a state of clamping the covered electric wire D so that the covering layer H can be peeled off by the cutter 5 for peeling off the covering layer. Then, the coated electric wire coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com