Brake disc and method for manufacturing same

A technology for brake discs and brake calipers, applied in the field of wear-reducing coatings and manufacturing such brake discs, can solve problems such as coating cracks and expensive manufacturing, and achieve the goals of preventing abrasion damage, low cost, and reduced wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

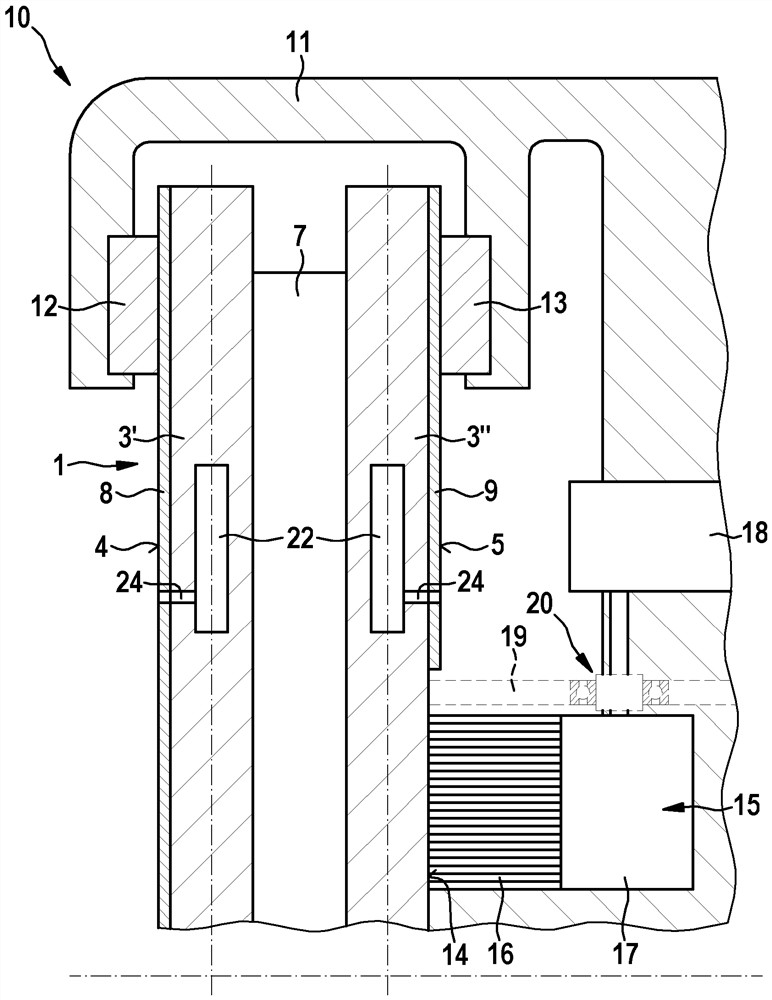

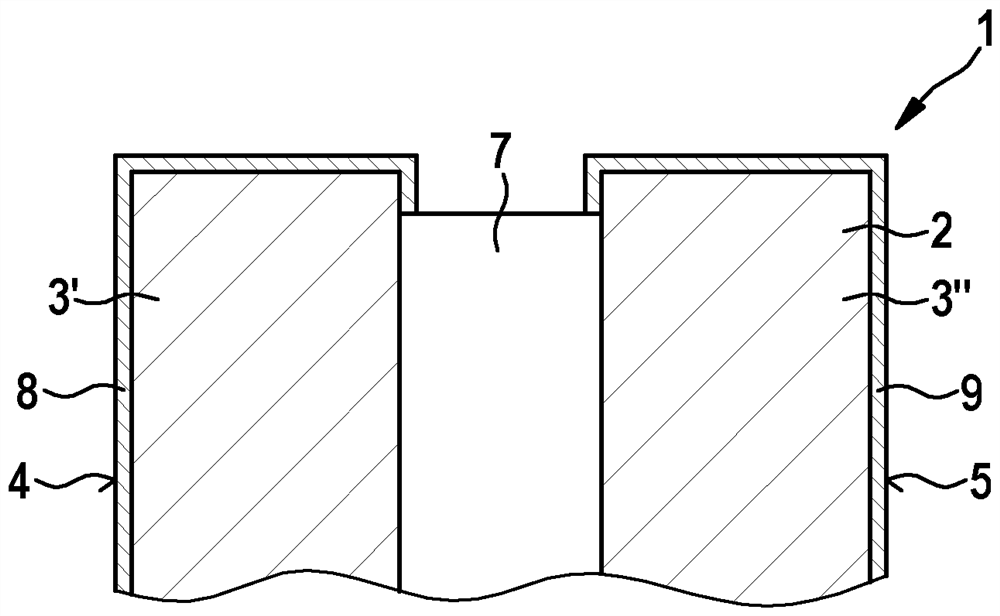

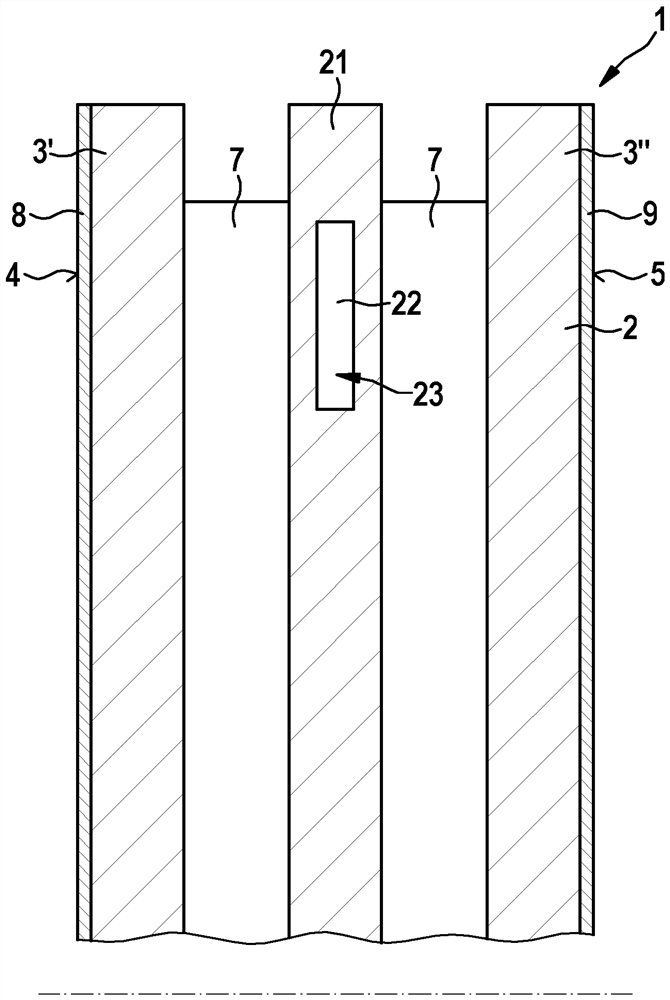

[0028] figure 1 A brake disk 1 for a motor vehicle (not shown) is shown in perspective. The brake disk 1 has a brake ring 3 which is formed by the base disk 2 . The braking ring 3 has a respective braking surface 4 or 5 on its two end faces. In the middle, the brake disk 1 has a mounting cup 6 for fastening the brake disk 1 to a wheel bearing or wheel of a motor vehicle. The support cup 6 can differ in terms of material from the brake ring and can be made of aluminum, for example. As a result, the unbounced mass is reduced and a more favorable heat transfer to the hub and rim is achieved. A plurality of bores for screw connections for fastening are formed on the support pot 6 . The braking surfaces 4 , 5 are subject to wear during operation, which has the consequence that the brake disk 1 must be replaced periodically. Today's brake discs are usually made of gray cast iron and some also of ductile iron or cast from suitable steel alloys and are thus machined by turning. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com