Heat laser strip device

A technology of stripping equipment and heating laser, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., and can solve problems such as residual stress and fragility of GaN epitaxial wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

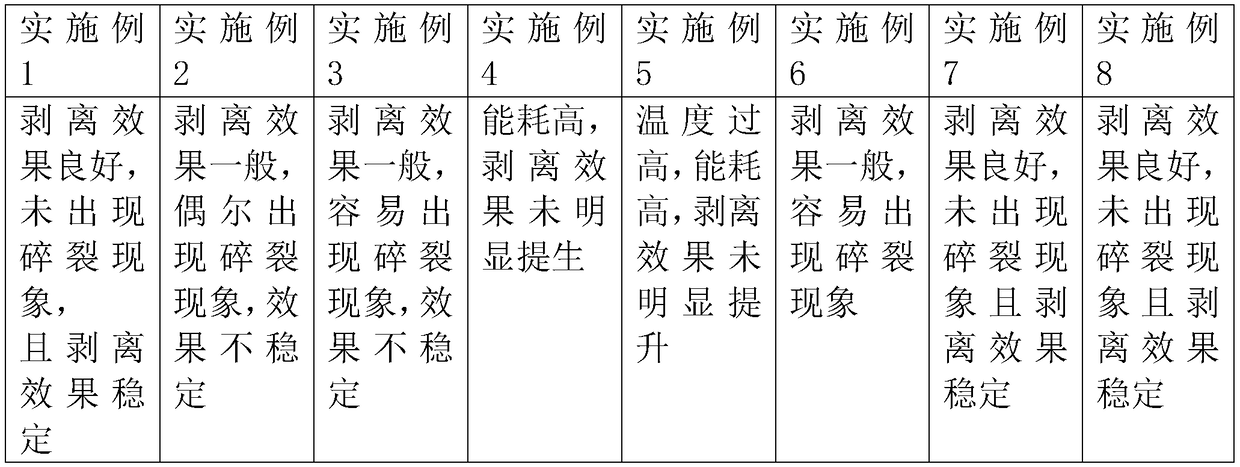

Embodiment 1

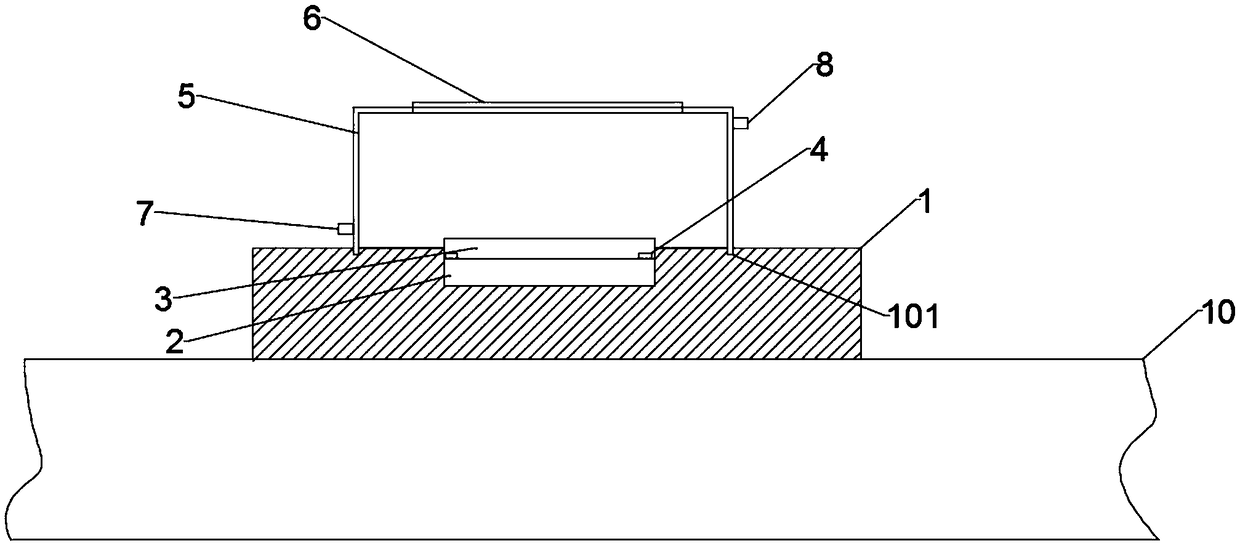

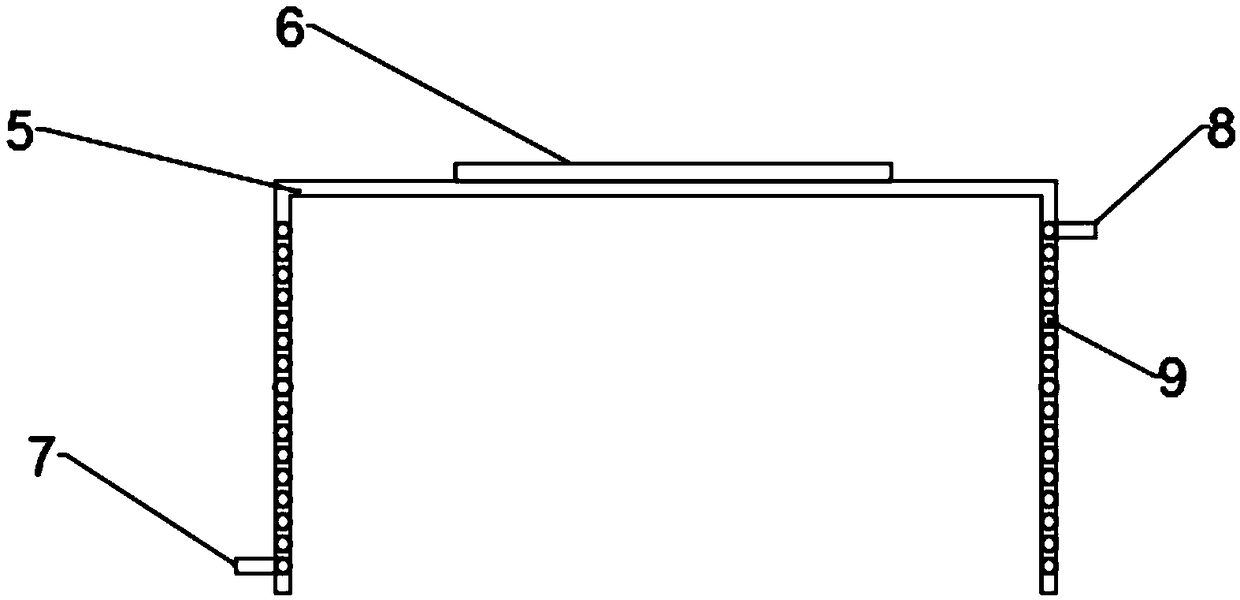

[0029] A heating laser peeling device, comprising a laser peeling device body (for the specific structure and usage of the laser peeling device body, refer to the patent in the background technology), the laser peeling device body includes a mobile platform 10 arranged at the lower end, such as figure 1 As shown, the mobile platform 10 is provided with a heating base 1, and the heating base 1 is provided with a sample stage. The electric heating device 2, the lower end of the sample table 3 is also provided with a thermocouple 4 for detecting the temperature of the sample table 3, the top of the sample table 3 is covered with a heat preservation cover 5, and the top of the heat preservation cover 5 is in contact with the sample table. The position corresponding to 3 is provided with a thermal insulation lens 6 which is convenient for the laser to pass through. The lower end of the heat preservation cover 6 is clamped and fixed in the groove 101 at the upper end of the heating ...

Embodiment 2

[0031] Others are the same as in Embodiment 1, except that the heat preservation cover 6 is not used to form a closed heating cavity.

Embodiment 3

[0033] Others are the same as in Example 1, except that the electric heating device 2 heats the sample stage to 600° C. or 700° C. within 4 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com