A bearing fault feature extraction method based on vmd parameter optimization

An extraction method and fault feature technology, which is applied in the field of bearing fault feature extraction based on VMD parameter optimization, can solve the problems of parameter dependence on experience acquisition, and the effect of decomposition has a large influence, so as to reduce the influence of noise and vibration frequency bands, increase Implementability, effect of reducing program runtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

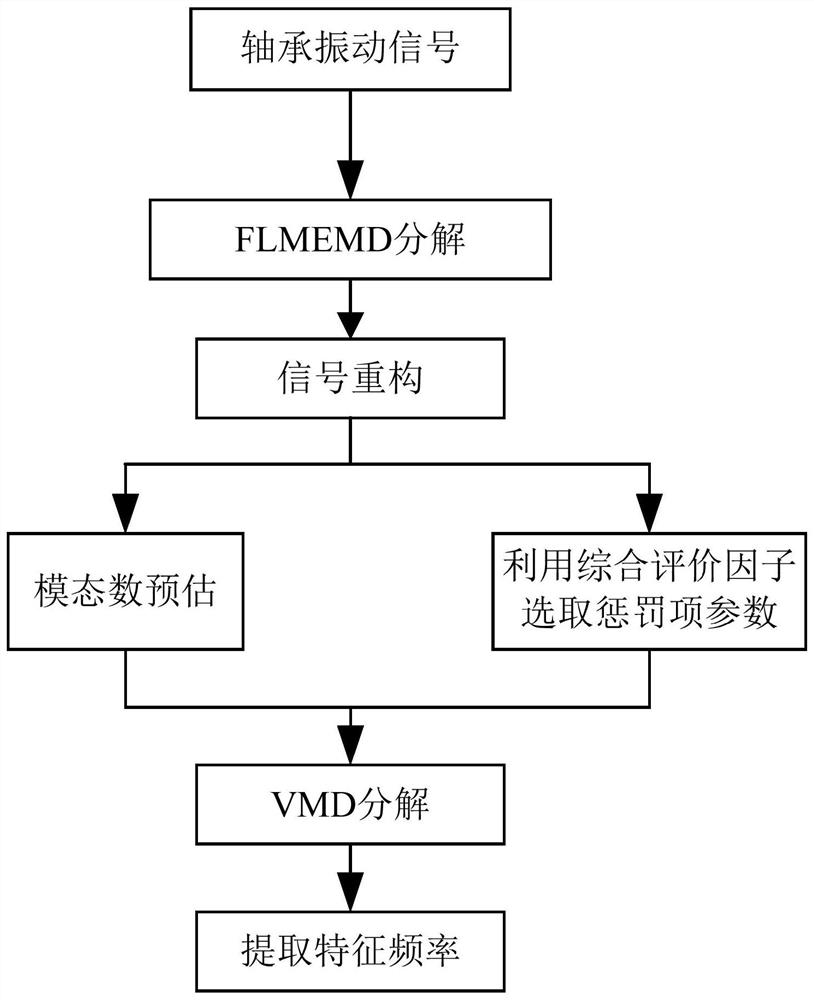

[0065] Such as figure 1 As shown, a bearing fault feature extraction method based on VMD parameter optimization, the method includes the following steps:

[0066] (1) Obtain the original vibration signal of the bearing;

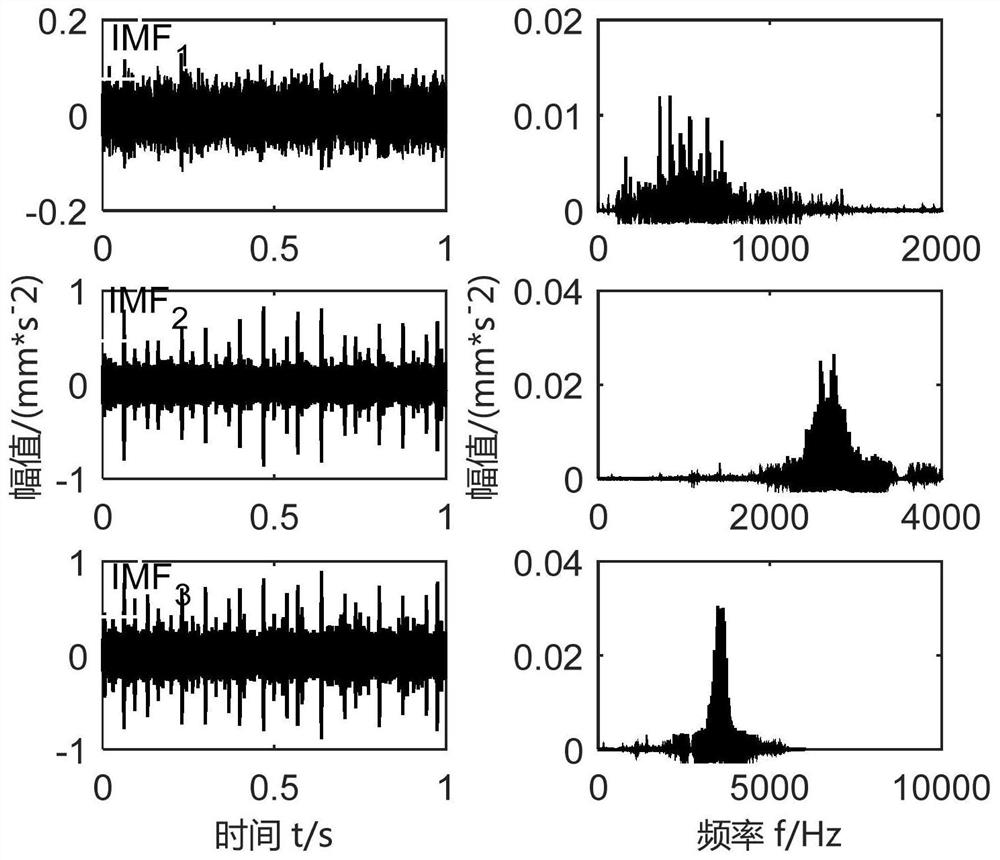

[0067] (2) Mode decompose and reconstruct the original vibration signal of the bearing to obtain the reconstructed signal;

[0068] (3) Obtain the modal number and secondary penalty parameters of VMD decomposition according to the original vibration signal of the bearing;

[0069] (4) VMD decomposition is performed on the reconstructed signal by using the obtained modal number and the secondary penalty parameter to obtain the bearing fault characteristic frequency.

[0070] Step (2) The fast local mean empirical mode decomposition method is used to decompose the original vibration signal of the bearing.

[0071] Step (2) performs fast local mean empirical mode decomposition on the original vibration signal of the bearing as follows:

[0072] (a1) Obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com