A kind of concrete strength testing equipment

A concrete strength and detection equipment technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of affecting the detection accuracy, reducing the detection efficiency, and small bonding area, so as to reduce the interference of external ultrasonic waves and improve the detection efficiency. Efficiency, the effect of increasing the bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

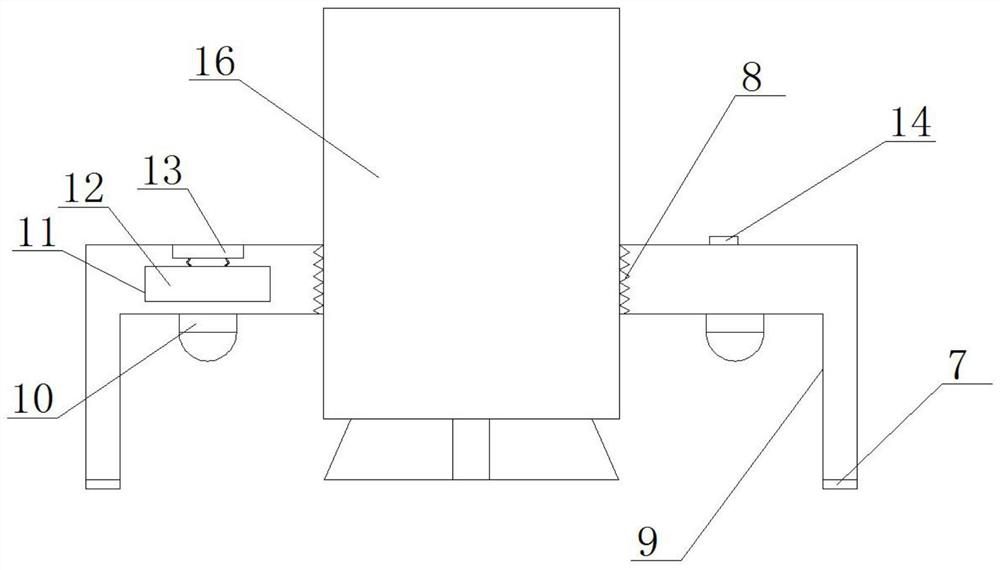

[0023] As a preferred embodiment of the present invention, the battery one 12 is electrically connected to the detection switch 14 through wires, and the detection switch 14 is electrically connected to the LED detection lamp 10 through wires.

[0024] As a preferred embodiment of the present invention, the charging socket 13 is electrically connected to the battery one 12 through a charging circuit.

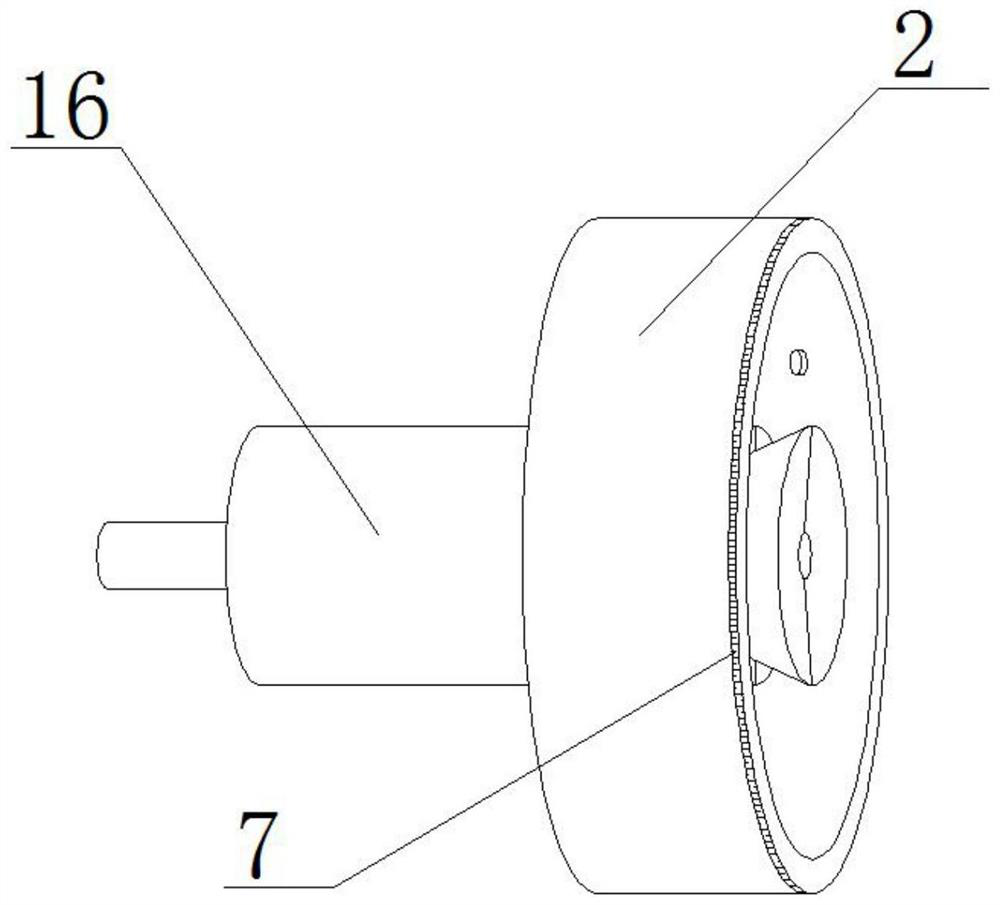

[0025] As a preferred embodiment of the present invention, the inner diameter of the annular cushion 7 is equal to the diameter of the circular groove 9 .

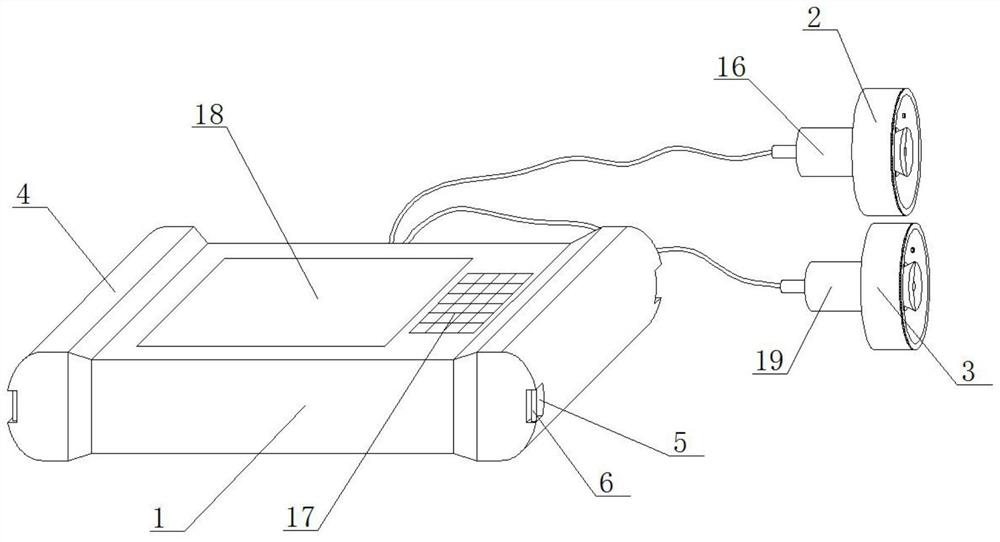

[0026] As a preferred embodiment of the present invention, the computer 15 is electrically connected to the operation buttons 17 and the ultrasonic receiver 16 respectively through a monitoring circuit.

[0027] As a preferred embodiment of the present invention, the computer 15 is electrically connected to the display screen 18 and the ultrasonic generator 19 respectively through a command circuit.

[0028] As a preferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com