Device and method for ion exchange resin monitoring and sampling in operation

An ion exchange resin and sampling device technology, applied in sampling devices, measuring devices, instruments, etc., can solve the problems of resin failure and scrap time cannot be pre-determined, residual exchange capacity, waste and other problems, achieve fast sampling speed, accurate determination, The effect of high sampling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

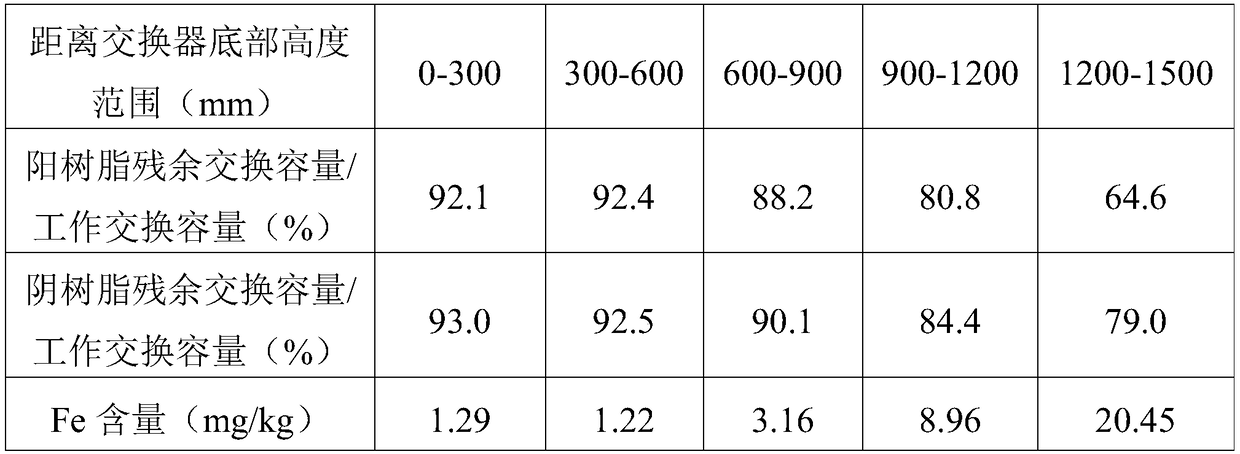

[0029] The resin in the stator cooling water ion exchanger of a generator set has been running for 10 months by the time the sampling work started. There is no problem during the operation, and the conductivity of the effluent has been in a qualified state for a long time. In view of the fact that the unit will be undergoing annual maintenance in the near future, in order to take into account the safety and economy of the unit, the on-site personnel cannot determine whether to replace the resin this time or in the next annual maintenance, so the present invention is used for analysis.

[0030] (1) Selection of sampling device material. The sampling device can be made of plastic, stainless steel or plexiglass, but in order to observe the resin in the ion exchanger, it is decided to use plexiglass.

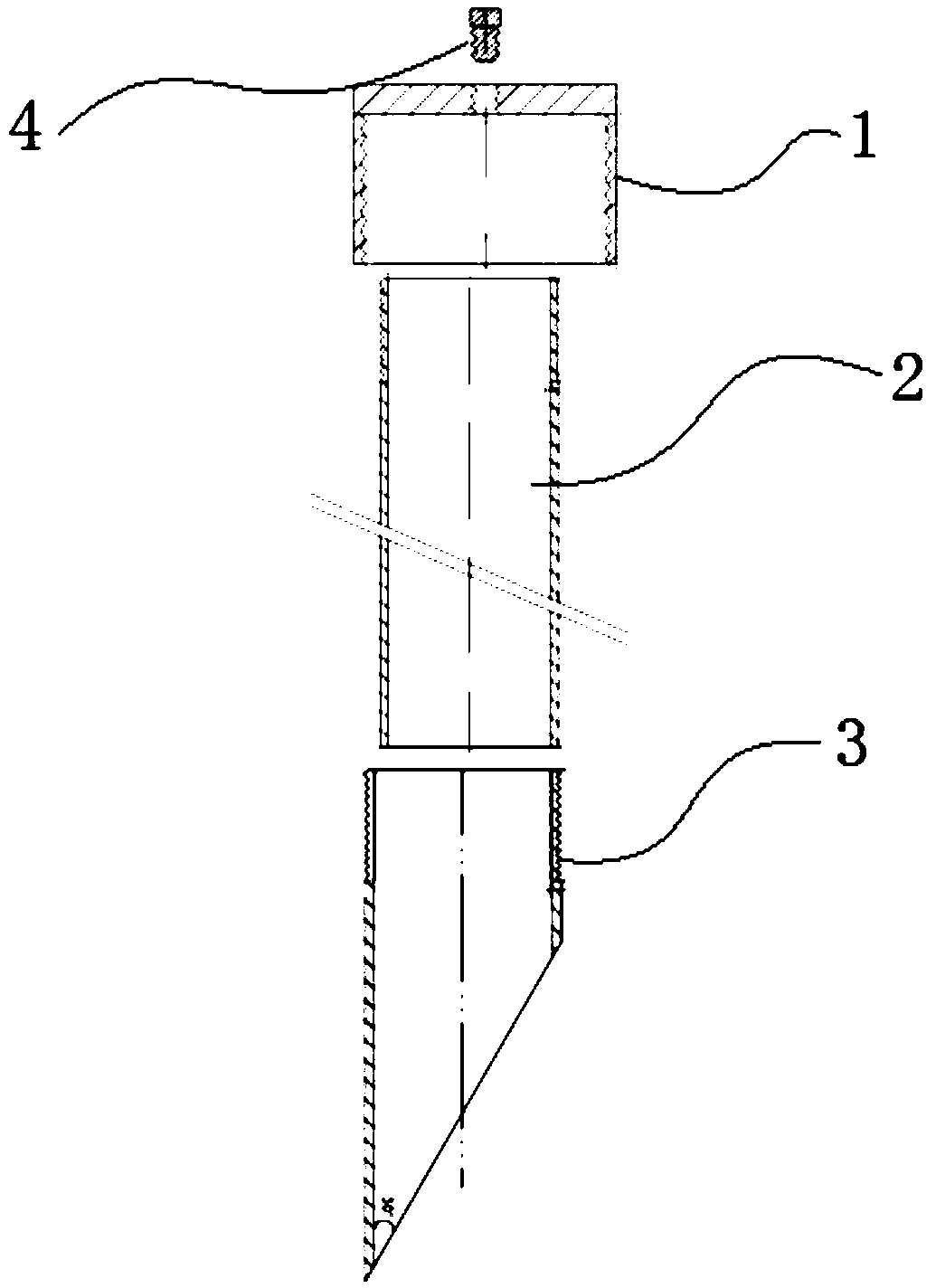

[0031] (2) Device fabrication. according to figure 1 Make the plug on the top of the sampling device and the wedge-shaped insertion port at the tail according to the content show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com