Chip drying mechanism

A drying mechanism and chip technology, which is applied in the direction of dryers, drying, local stirring dryers, etc., can solve the problems that water vapor is not easily emitted, affecting processing efficiency and processing quality, so as to reduce the impact of water vapor and ensure Processing quality, the effect of avoiding aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

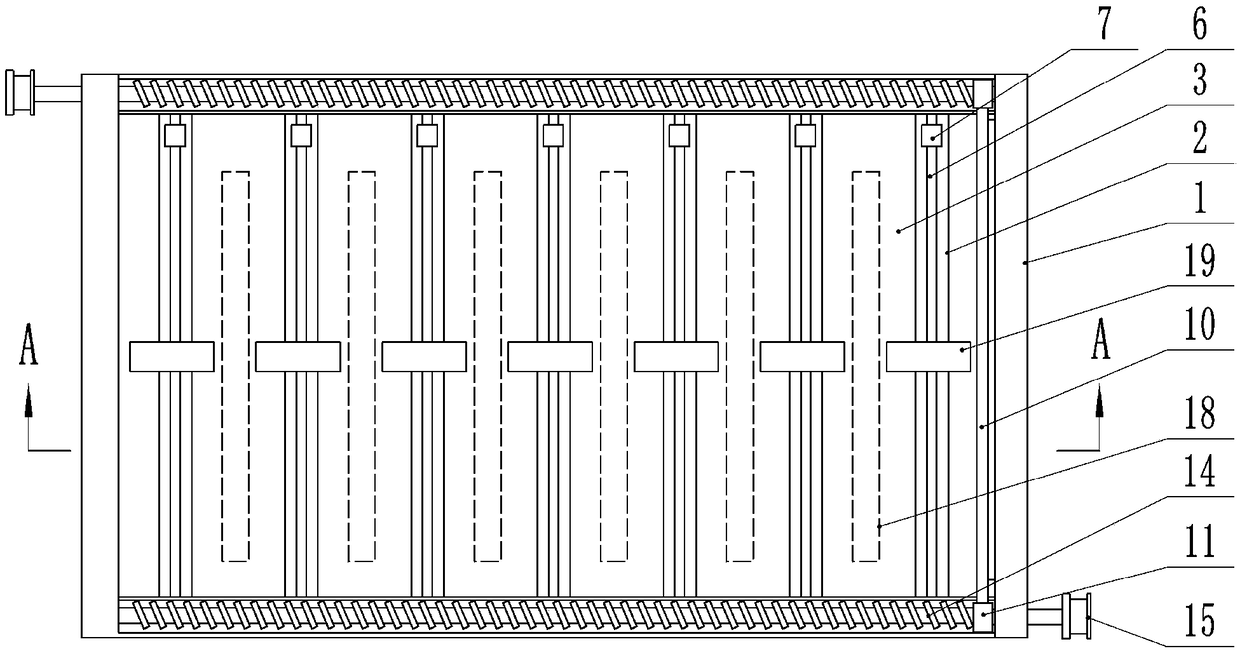

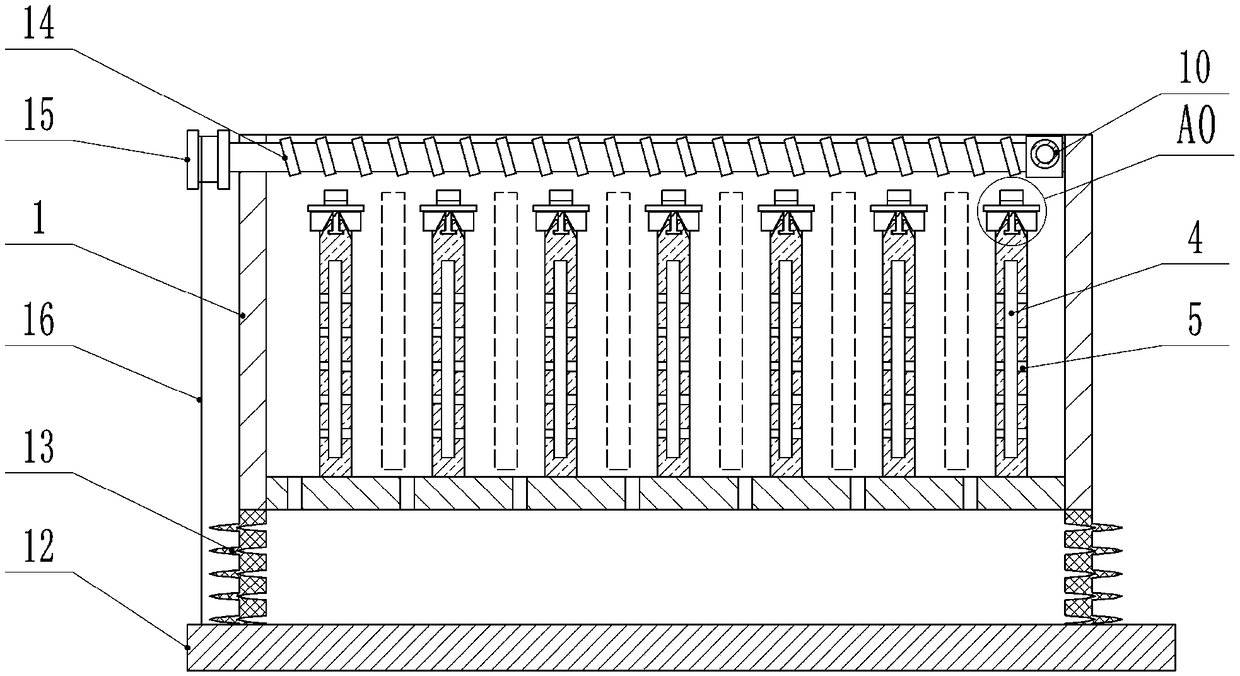

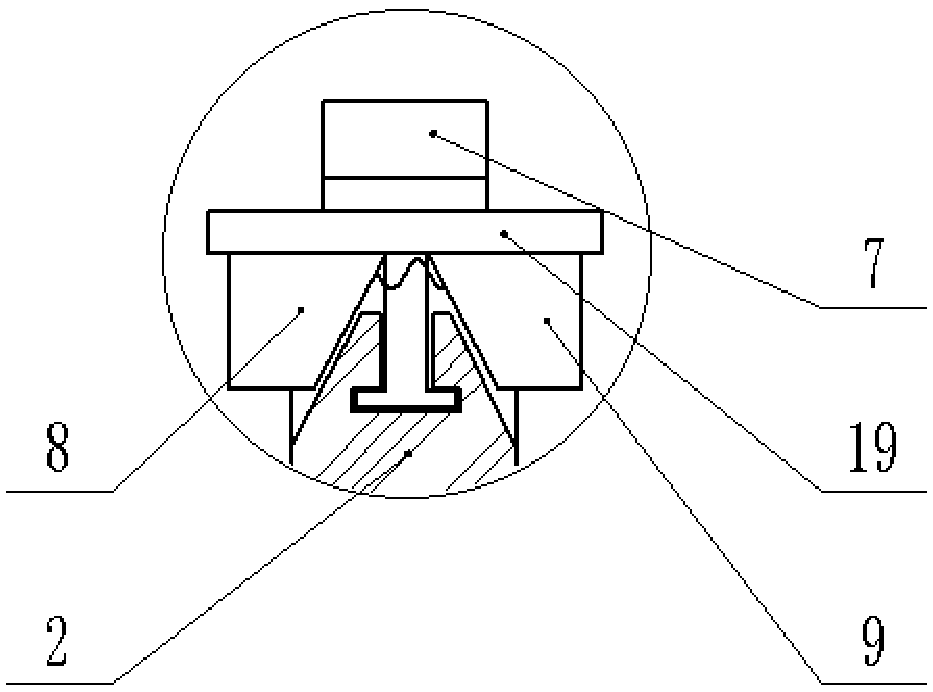

[0023] The reference signs in the drawings of the description include: drying tank 1, partition plate 2, slot 3, cavity 4, heat release hole 5, chute 6, slider 7, first wedge 8, second wedge 9. Negative pressure tube 10, sliding sleeve 11, bottom plate 12, telescopic tube 13, lead screw 14, reel 15, stay cord 16, telescopic plate 17, disc body 18, connecting plate 19.

[0024] Example figure 1 with figure 2 Commonly shown: chip drying mechanism, including a drying tank 1 with an upward opening, in which there are seven parallel and transversely distributed partitions 2, and there are gaps between adjacent partitions 2 to form slots 3 , the seven-side partition 2 forms a total of six slots 3 for placing and drying the disc body 18 with chips mounted on six sides. Cavities 4 are provided in the partitions 2, and heat sources are installed in the cavities 4. The heat sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com