Air conditioner unit heat preservation panel with sound attenuation function

A technology for air-conditioning units and appliances, applied in the field of thermal insulation and sound insulation materials, which can solve problems such as increased energy consumption, increased wind resistance, and increased costs, and achieve the effects of reducing noise and excellent thermal insulation and sound insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

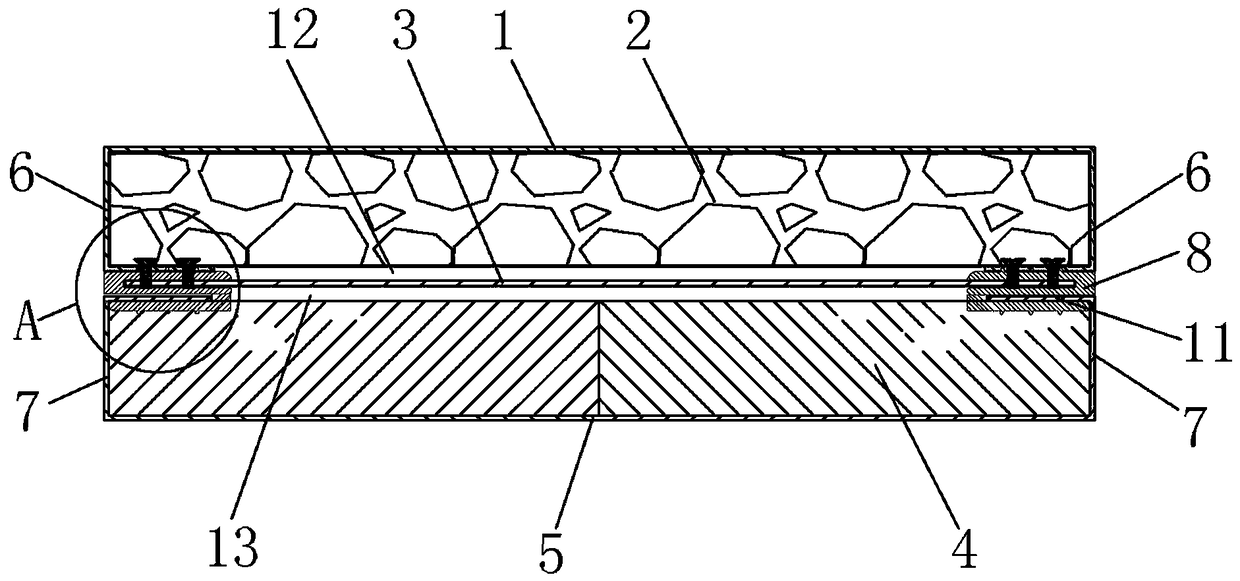

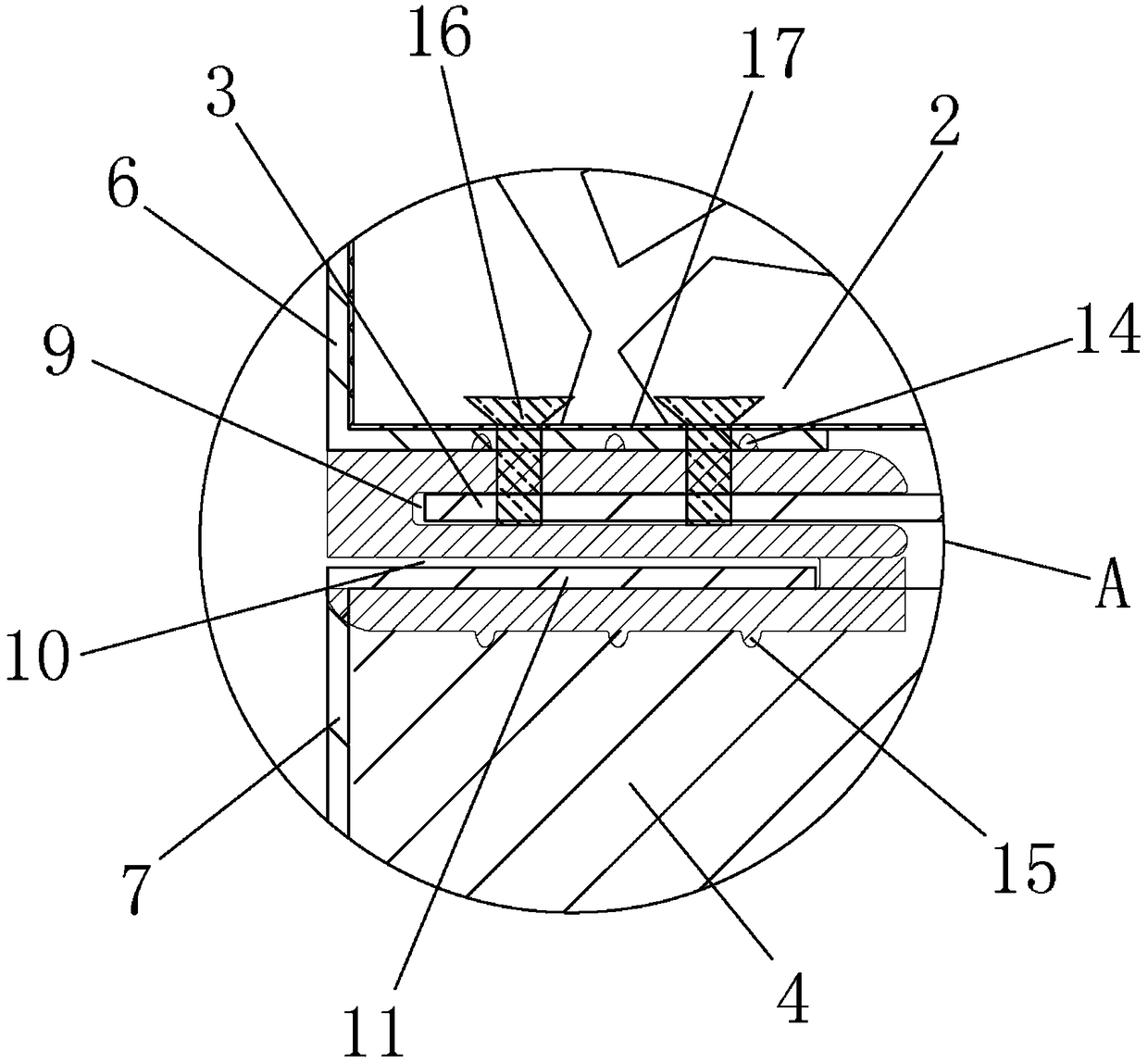

[0018] refer to figure 1 , figure 2 , a thermal insulation panel with a sound-absorbing function for an air-conditioning unit, comprising a perforated sound-absorbing panel 1, a glass wool layer 2, an inner metal plate 3, an insulating layer 4, and an outer metal plate 5 sequentially stacked from the inside to the outside, the perforated sound-absorbing panel The board 1 is provided with uniformly distributed micro-holes with a diameter of 0.5-1.0 mm, the perforated sound-absorbing board 1 has a porosity of 1%-3%, and the thickness of the inner metal plate 3 is the same as that of the outer metal plate 5 The thickness of the perforated sound-absorbing board 1 is 0.5%-4% of the thickness of the glass wool layer 2, and the thickness of the outer metal plate 5 is 0.25%-4% of the thickness of the thermal insulation layer 4 %, in this embodiment, the thickness of the perforated sound-absorbing panel 1 is 0.5-1.0 mm, the thickness of the perforated sound-absorbing panel 1, the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com