A non-magnet anti-idling integrated modular temperature-resistant and corrosion-resistant high-lift self-priming pump

A modular, self-priming pump technology, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, can solve problems such as easy leakage, complex love and failure, and intolerance to idling, and achieve simple transmission, Solve the effect of narrow magnetic gap and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

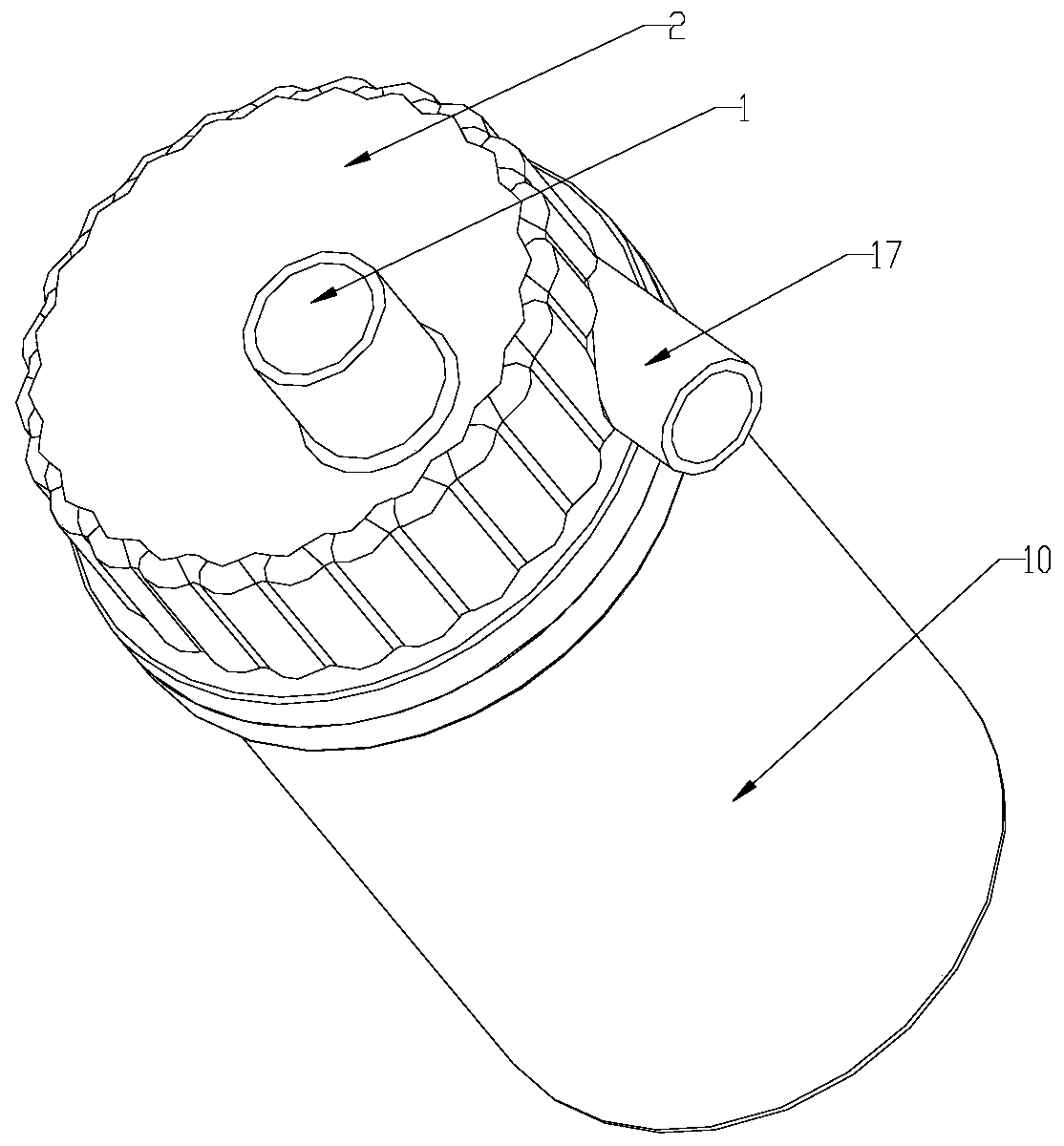

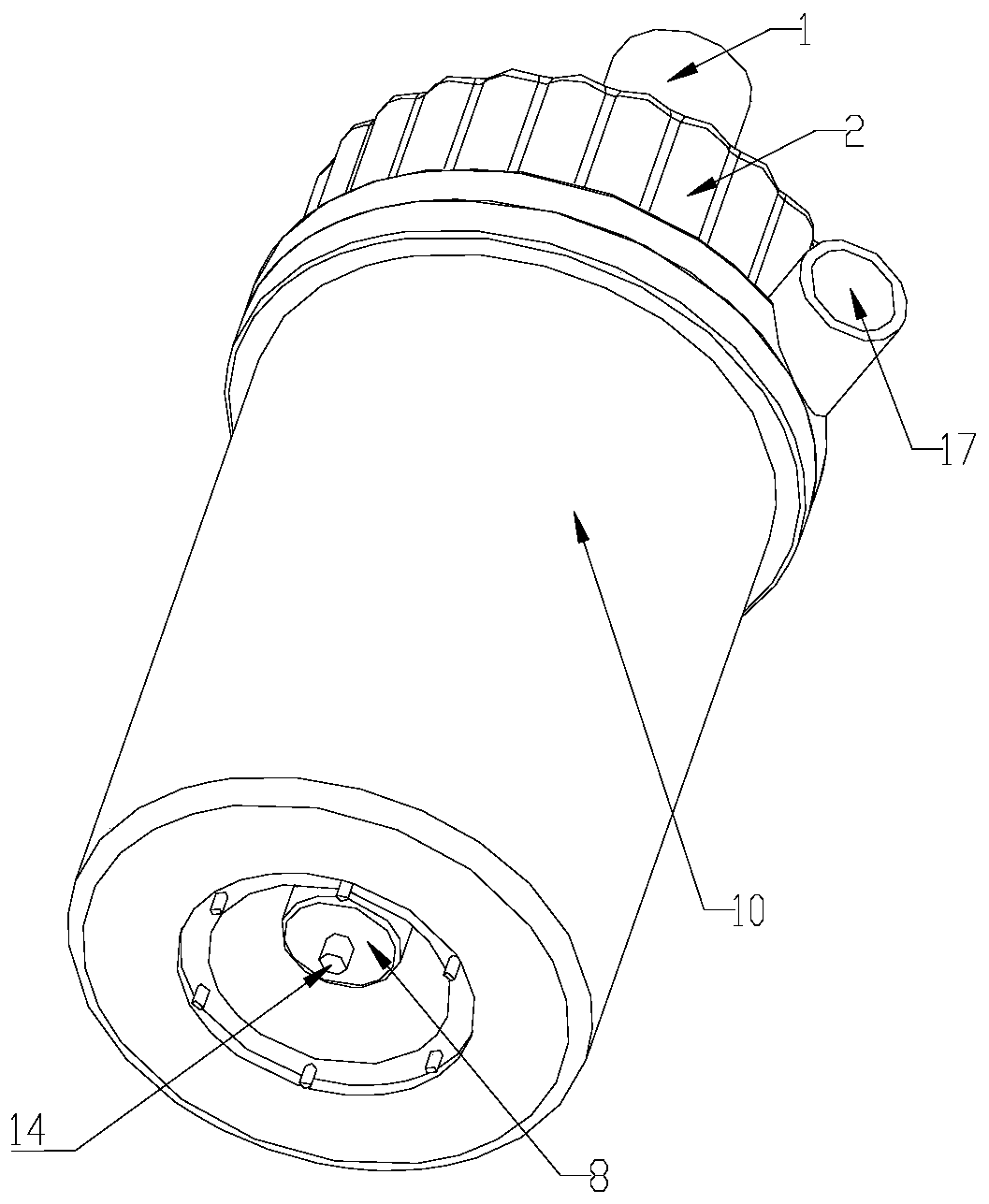

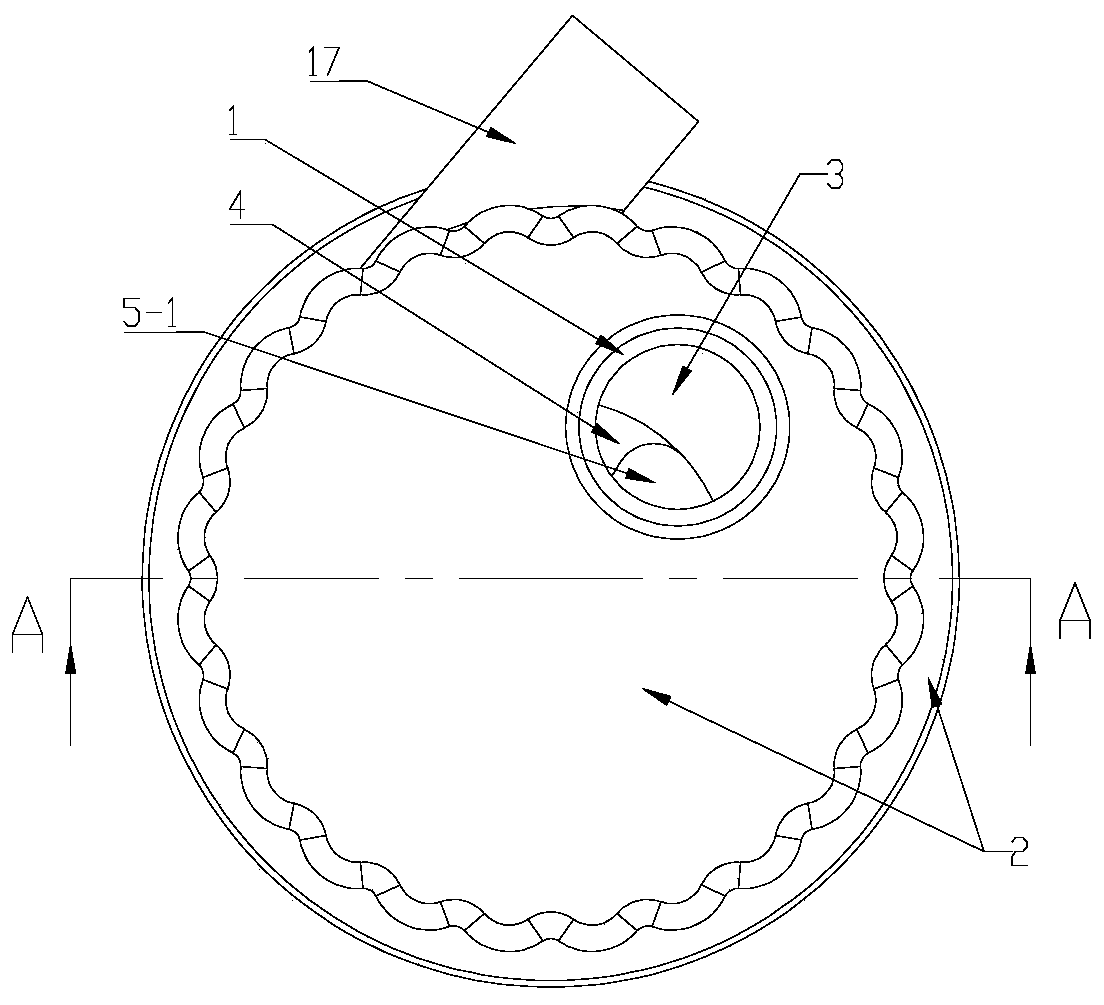

[0052] see Figure 1 to Figure 12 , a magnet-free idling-resistant integrated modular temperature-resistant and corrosion-resistant self-priming pump, including a motor and a pump head driven by the motor to suck liquid; it is characterized in that,

[0053] - The motors mentioned include:

[0054] The motor housing 10 is made of plastic; different plastic housings can be used according to the operating temperature conditions. Generally, PP can be used at temperatures below 80°, and FD4 tetrafluoroplastics can be used at temperatures above 80° to 200°.

[0055] There are two corrosion-resistant bearing seats 7, which are respectively embedded in the two ends of the motor housing 10;

[0056] Corrosion-resistant motor shaft 14, the two ends of which are connected in the corrosion-resistant bearing seat 7 with 8 corrosion-resistant bearings;

[0057] The rotor assembly is formed by coating the rotor plastic shell 13 on the surface of the rotor 11; it is sleeved on the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com