Oil leakage-free and low-noise rotor driving mechanism of vacuum pump

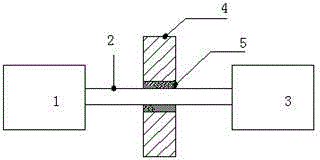

A driving mechanism and vacuum pump technology, which is applied in the direction of machines/engines, liquid fuel engines, pumping devices for elastic fluids, etc., and can solve the oil leakage noise of the vacuum pump, the aging of the sealing ring 5, and the easy wear of the sealing ring, etc. problems, to achieve the effect of avoiding oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

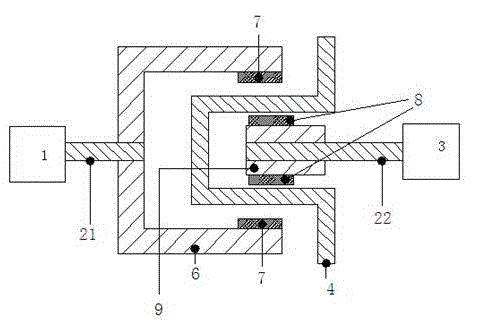

[0019] see figure 2 , which is an oil-leakage-free, low-noise rotor drive mechanism in a vacuum pump of the present invention. As shown in the figure: it includes a motor 1, a shaft and a rotor 3; the motor 1 is connected to a connecting body 6 through a first shaft 21, a first magnet 7 is installed inside the connecting body 6, and the vacuum pump housing 4 is arranged on the first magnet 7, between the housing walls of the vacuum pump housing 4 between the first magnets 7, there is also a second shaft 22 on which a second magnet 8 is installed, and one end of the second shaft 9 is connected to the rotor 3; the second magnet The position of 8 corresponds to the position of the first magnet 7 .

[0020] When the present invention is in use, the first shaft 21 is driven by the motor 1 to rotate, and the first shaft 21 further drives the connecting body 6 to rotate. Due to the magnetic force coupling between the first magnet 7 and the second magnet 8, the shaft attachment 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com