A method for preparing micron-sized monodisperse polymer microspheres at room temperature

A monodisperse microsphere, micron-scale technology, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problems of limited application and difficult removal, and achieve the effect of simple and reliable method, short time consumption and high yield of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

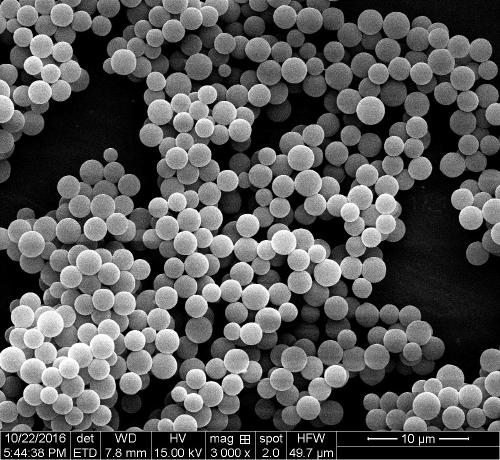

[0030] 1560 μL of toluene diisocyanate and 2365 μL of trimethylolpropane tris(3-mercaptopropionate) were added to 10 mL of triethylamine in acetonitrile solution at a concentration of 0.00158 g / L, and mixed well; then the two parts of the solution Put it in a reaction container and mix it evenly, seal it; let it stand at room temperature for 2 hours to react; the obtained product is washed successively with acetone and n-hexane, centrifugally precipitated, and vacuum-dried to obtain monodisperse microspheres. The average particle size of the obtained product is 2.259 μm, the polydispersity coefficient is 1.049, and the yield of microspheres is 98.7% ( figure 1 ).

Embodiment 2

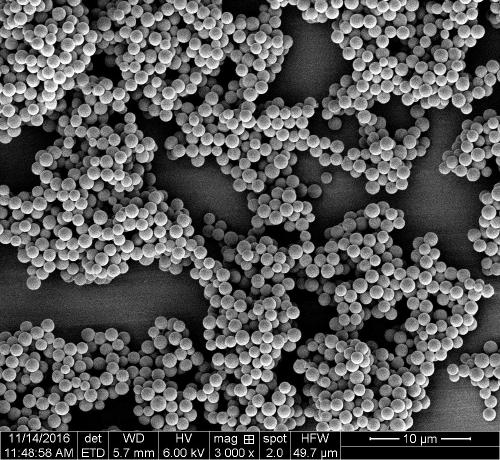

[0032] 1025 μL of toluene diisocyanate and 1580 μL of trimethylolpropane tris(3-mercaptopropionate) were added to 10 mL of triethylamine in acetonitrile solution at a concentration of 0.00105 g / L, and mixed well; then the two parts of the solution Put it in a reaction container and mix it evenly, seal it; let it stand at room temperature for 2 hours to react; the obtained product is washed successively with acetone and n-hexane, centrifugally precipitated, and vacuum-dried to obtain monodisperse microspheres. The average particle size of the obtained product was 2.259 μm, the polydispersity coefficient was 1.023, and the yield of microspheres was 96.6%.

Embodiment 3

[0034] 1085 μL of toluene diisocyanate and 1517 μL of trimethylolpropane tris(3-mercaptopropionate) were added to 10 mL of triethylamine in acetonitrile solution at a concentration of 0.00107 g / L, and mixed well; then the two parts of the solution Put it in a reaction container and mix it evenly, seal it; let it stand at room temperature for 2 hours to react; the obtained product is washed successively with acetone and n-hexane, centrifugally precipitated, and vacuum-dried to obtain monodisperse microspheres. The average particle size of the obtained product was 2.263 μm, the polydispersity coefficient was 1.034, and the yield of microspheres was 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com