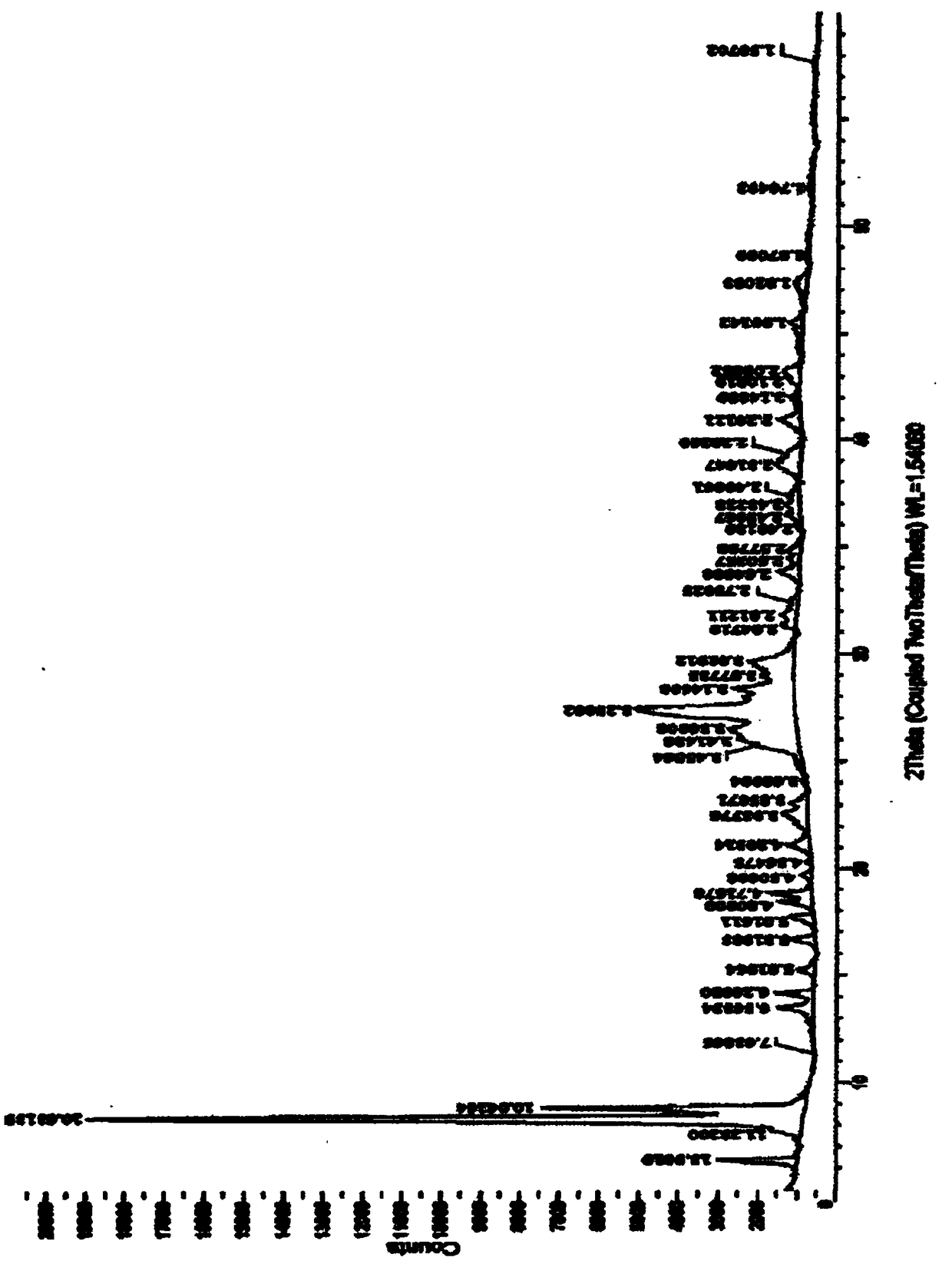

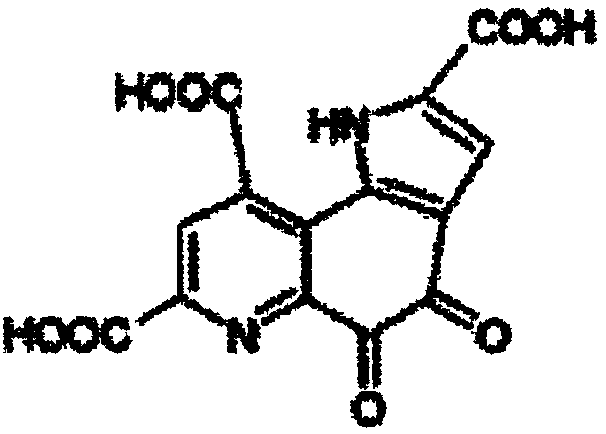

Pyrroloquinoline quinone disodium salt crystal and preparation method thereof

A technology of pyrroloquinoline quinone disodium salt and pyrroloquinoline quinone, which is applied in the field of pyrroloquinoline quinone disodium salt crystal and its preparation, can solve the problems that affect the popularization and use of PQQ, easy moisture absorption, poor stability, etc., and achieve Regular crystal shape, good stability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

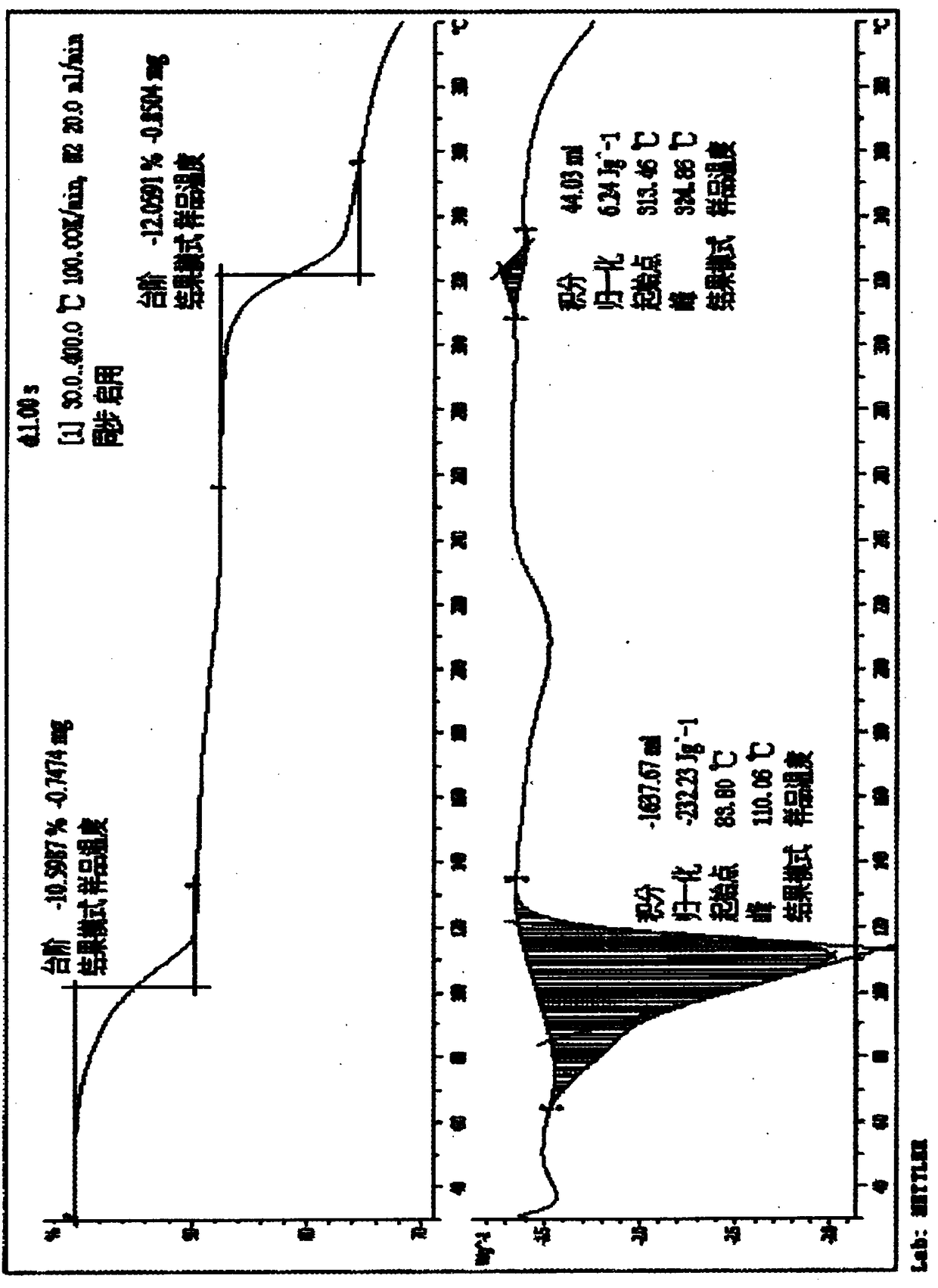

Embodiment 1

[0055]Add 100 g of pyrroloquinoline quinone acid in free form to 10 L of water, stir to form a suspension, add sodium hydroxide to adjust the pH to 8.5, and stir for 15 minutes to completely dissolve; filter to obtain the filtrate, slowly add hydrochloric acid under stirring to adjust the pH to 3.5; Nanofiltration desalination of nanofiltration membrane with a molecular weight of 150-300D, washing with purified water until the conductivity of the permeate is ≤50μS / cm, and ending; vacuum concentration and crystallization, the internal temperature of the feed liquid during the concentration process is 25-35°C; suction filtration, washing wet The product was vacuum-dried at 50°C for 6 hours to obtain 109.5 g of crystals. The obtained crystal is detected, and its purity measured by HPLC is 99.7%; the Na ion content is detected by cation chromatography, and the PQQ content is recorded in conjunction with the HPLC external standard method, and the mass ratio of PQQ and Na contained i...

Embodiment 2

[0057] Add 100 g of pyrroloquinoline quinone monosodium salt into 10 L of water, stir to form a suspension, add sodium hydroxide to adjust the pH to 7.5, and stir for 15 minutes to completely dissolve; filter to obtain the filtrate, slowly add hydrochloric acid to adjust the pH to 3.2 while stirring; Nanofiltration desalination of nanofiltration membrane with a molecular weight cut-off of 150-300D, washing with purified water until the conductivity of the permeate is ≤50μS / cm, and ending; vacuum concentration and crystallization, the internal temperature of the feed liquid during the concentration process is 25-35°C; suction filtration, washing The wet product was vacuum-dried at 60°C for 5 hours to obtain 96.8 g of crystals. The obtained crystal is detected, and its purity measured by HPLC is 99.8%; the Na ion content is detected by cation chromatography, and the PQQ content is recorded in conjunction with the HPLC external standard method, and the mass ratio of PQQ and Na con...

Embodiment 3

[0059] Add 100 g of pyrroloquinoline quinone trisodium salt into 10 L of water, stir to form a suspension, add sodium hydroxide to adjust the pH to 8.0, and stir for 15 minutes to completely dissolve; filter to obtain the filtrate, slowly add sulfuric acid under stirring to adjust the pH to 3.7; Nanofiltration desalination of nanofiltration membrane with a molecular weight cut-off of 150-300D, washing with purified water until the conductivity of the permeate is ≤50μS / cm, and ending; vacuum concentration and crystallization, the internal temperature of the feed liquid during the concentration process is 25-35°C; suction filtration, washing The wet product was vacuum-dried at 40°C for 10 hours to obtain 78.3 g of crystals. The obtained crystal is detected, and its purity measured by HPLC is 99.7%; the Na ion content is detected by cation chromatography, and the PQQ content is recorded in conjunction with the HPLC external standard method, and the mass ratio of PQQ and Na contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com