Ecological concrete and preparation method thereof

An ecological concrete and concrete technology, which is applied in the direction of chemical instruments and methods, ceramic products, and other household appliances, can solve the problems of destroying the distribution balance of algae, destroying natural biological habitats, and fragile ecosystems, so as to facilitate the purification of water quality , conducive to the effect of reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides the preparation method of aforementioned ecological concrete, which comprises the following steps:

[0052] (1) pre-stirring and mixing other materials except graphene or its derivatives in the raw materials to obtain a concrete premix matrix; the amount of water used for pre-mixing is 87.5-97.5% by weight of the water amount of the mixing ratio;

[0053] (2) When the concrete premix matrix still has fluidity, add the dispersion liquid of graphene or its derivatives therein, stir and mix again, obtain concrete mixture; the dispersion liquid of described graphene or its derivatives The solvent is water; the amount of water in the dispersion is: the amount of water in the mix ratio minus the amount of water used for pre-mixing;

[0054] (3) The concrete mixture is injected into a mould, and the ecological concrete is obtained after molding and demoulding.

[0055] It should be noted that the preparation method of the dispersion liquid ...

Embodiment 1

[0058] The preparation of embodiment 1 ecological concrete

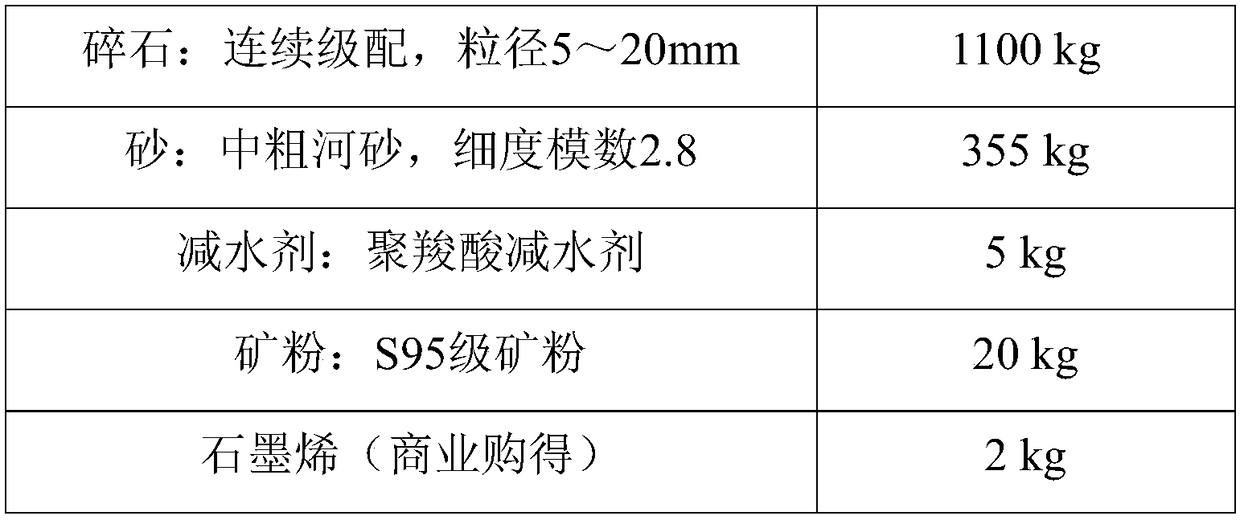

[0059] The mix ratio of concrete is shown in Table 1

[0060] Table 1

[0061]

[0062]

[0063] The preparation process is as follows:

[0064] According to the mixing ratio recorded in Table 1, after mixing cement, crushed stone and sand, add water reducing agent, mineral powder and 90% by weight of water, and carry out pre-mixing; to obtain the concrete premixed matrix; at 45 After 10 minutes, when the concrete premix matrix still has fluidity, add graphene oxide dispersion liquid (graphene 2kg is dispersed in the water yield of 10% by weight proportion), after fully stirring and mixing again, obtain concrete mixture; The concrete mixture is poured into the mold, and the finished product is made after molding and demoulding.

Embodiment 2

[0065] The preparation of embodiment 2 ecological concrete

[0066] The mix ratio of concrete is shown in Table 2

[0067] Table 2

[0068]

[0069]

[0070] The preparation process is as follows:

[0071] According to the mixing ratio recorded in Table 2, after mixing cement, crushed stone and sand, adding water reducer, mineral powder, straw and 95% by weight of water in the mixing ratio, pre-mixing and mixing; to obtain the concrete premixed matrix; After 45 minutes, when the concrete premix matrix still has fluidity, add the graphene oxide dispersion (graphene oxide 1kg is dispersed in the water yield of 5% by weight), and then fully stir and mix to obtain the concrete mixture; The concrete mixture is poured into a mold, and the finished product is obtained after molding and demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com