Algae and phosphorus removal agent for treating eutrophic water body as well as preparation method and application of algae and phosphorus removal agent

A technology of eutrophication and chemicals, which is applied in the field of algae and phosphorus removal chemicals, can solve the problems of ineffective removal of phosphorus and inability to effectively remove algae in water bodies, and achieve the effect of avoiding outbreaks again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

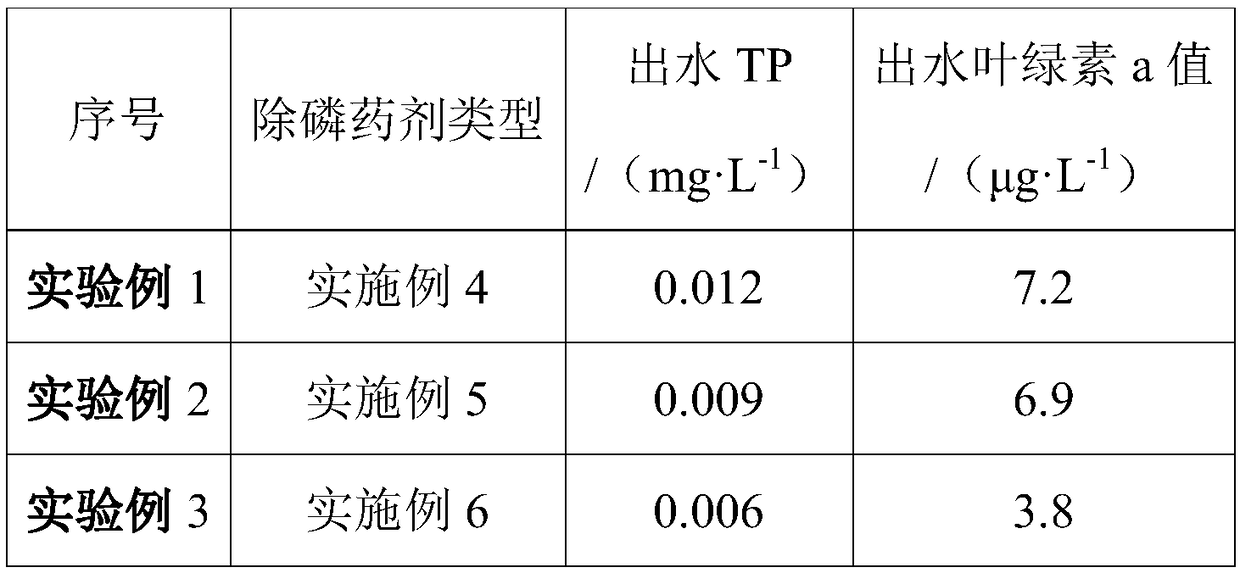

Examples

preparation example Construction

[0031] Corresponding to the above-mentioned algae and phosphorus removal agent, the present invention also provides its preparation method, which includes:

[0032] (1) obtain bentonite, graphene or derivatives thereof, and magnetic powder;

[0033] (2) Mix bentonite, graphene or its derivatives, and magnetic powder, and stir with water to obtain a mixed wet material, wherein: the mass ratio of bentonite to graphene or its derivatives is: 1:1~1:10; The mass ratio to graphene or its derivatives is: 1:20~1:50;

[0034] (3) Dry the mixed wet material to obtain the algae and phosphorus removal agent.

[0035] In some specific embodiments of the present invention, in the case where the bentonite is sodium bentonite, the sodium bentonite is prepared by the following method:

[0036] Mix bentonite with water of 1-10 times the mass of bentonite, stir and heat to 50-80°C; add sodium carbonate with 3-6% of the mass of bentonite, stir at constant temperature for 30-120min; dry and pulv...

Embodiment 1

[0044] Embodiment 1 prepares sodium-based bentonite

[0045] Put bentonite into a reactor with temperature control and stirring functions, slowly add water 8 times the mass of bentonite, stir and heat up to 80°C; add sodium carbonate with 5% mass of bentonite, and stir at constant temperature for 90 minutes; mix the obtained mixture Dry and crush to 200 mesh to obtain sodium bentonite.

Embodiment 2

[0046] The preparation of embodiment 2 graphene oxide

[0047] Add natural flake graphite (2g), NaNO 3 (1g) and KMnO 4 (6g), stirred and reacted at 1-15°C for 10-30 minutes to obtain a reaction solution; raised the temperature of the reaction solution to 30-40°C and continued to stir for 20-40 minutes; then added deionized water to the reaction solution while stirring , control the temperature of the reaction solution within 100°C, and continue to stir for 30 minutes. Dilute the reaction solution to 10-20 times with deionized water, then add 30% H 2 o 2 (2ml), filtered while hot, fully washed with 5% (mass fraction) dilute HCl and deionized water until there was no SO in the filtrate 4 2- (with BaCI 2 solution detection), and obtain graphene oxide after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com