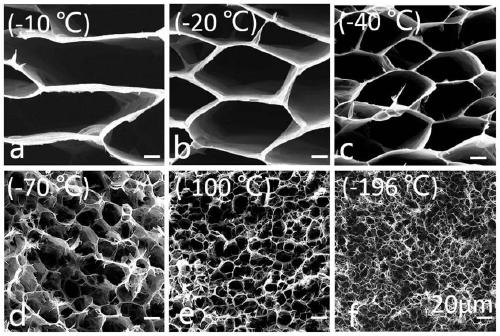

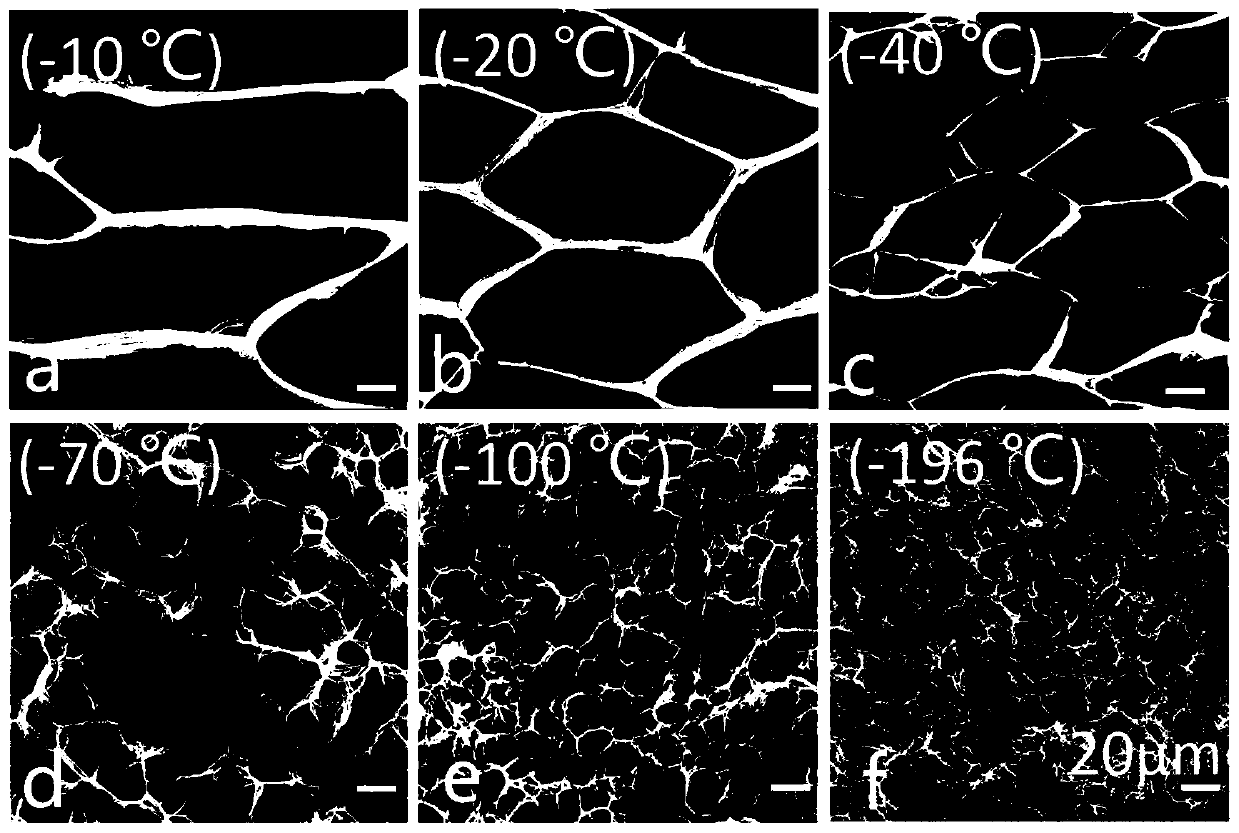

A preparation method of graphene airgel with adjustable pore size

A graphene airgel and graphene technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as unsatisfactory, limited performance, and improvement, and achieve high mechanical properties, thermal and electrical conductivity, and high The effects of directional adsorption performance and high compression recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing graphene aerogels with high electrical and thermal conductivity and high mechanical properties using specific freezing equipment, comprising the steps of:

[0031] (1) To prepare graphene oxide suspension, take 3g of graphite flakes and add 1.5g of sodium nitrate, add 90ml of concentrated sulfuric acid in an ice bath, stir for 4h, slowly add 9g of potassium permanganate, and stir at 30°C for 24h; slowly add 200ml of deionized water at 40°C, after cooling to room temperature, slowly add 10ml of hydrogen peroxide dropwise and stir for 15min; add 30ml of concentrated hydrochloric acid and let it stand for more than 12h, drain the supernatant, repeat this process twice, and the remaining dark yellow The suspension is transferred into a dialysis bag for dialysis until the pH value is greater than 6. This process lasts for more than 4 days. The unoxidized graphite is removed by centrifugal dispersion at a speed of 8000-10000rpm for many times, and the su...

Embodiment 2

[0039] A method for preparing graphene aerogels with high electrical and thermal conductivity and high mechanical properties using specific freezing equipment, comprising the steps of:

[0040] (1) To prepare graphene oxide suspension, take 3g of graphite flakes and add 1.5g of sodium nitrate, add 90ml of concentrated sulfuric acid in an ice bath, stir for 4h, slowly add 9g of potassium permanganate, and stir at 30°C for 24h; slowly add 200ml of deionized water at 40°C, after cooling to room temperature, slowly add 10ml of hydrogen peroxide dropwise and stir for 15min; add 30ml of concentrated hydrochloric acid and let it stand for more than 12h, drain the supernatant, repeat this process twice, and the remaining dark yellow The suspension is transferred into a dialysis bag for dialysis until the pH value is greater than 6. This process lasts for more than 4 days. The unoxidized graphite is removed by centrifugal dispersion at a speed of 8000-10000rpm for many times, and the supe...

Embodiment 3

[0048] A method for preparing graphene aerogels with high electrical and thermal conductivity and high mechanical properties using specific freezing equipment, comprising the steps of:

[0049] (1) To prepare graphene oxide suspension, take 3g of graphite flakes and add 1.5g of sodium nitrate, add 90ml of concentrated sulfuric acid in an ice bath, stir for 4h, slowly add 9g of potassium permanganate, and stir at 30°C for 24h; slowly add 200ml of deionized water at 40°C, after cooling to room temperature, slowly add 10ml of hydrogen peroxide dropwise and stir for 15min; add 30ml of concentrated hydrochloric acid and let it stand for more than 12h, drain the supernatant, repeat this process twice, and the remaining dark yellow The suspension is transferred into a dialysis bag for dialysis until the pH value is greater than 6. This process lasts for more than 4 days. The unoxidized graphite is removed by centrifugal dispersion at a speed of 8000-10000rpm for many times, and the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com