Special automatic circular pipe plasma cutting machine for expressway construction process and use method

A highway, plasma technology, applied in the direction of plasma welding equipment, welding/cutting auxiliary equipment, application, etc., can solve the problems of dangerous cutting process, loose round pipe clamp, round pipe compression deformation, etc., to achieve good cutting effect, improve Work efficiency, smooth cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

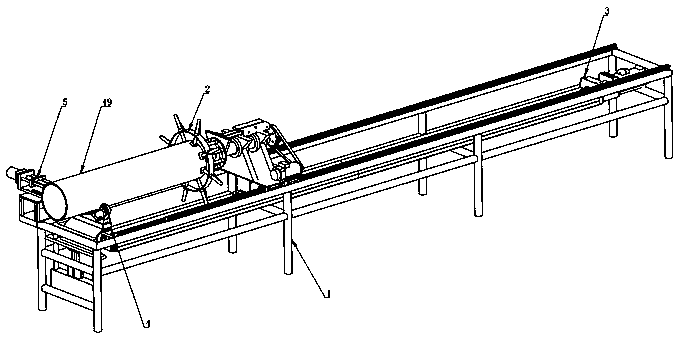

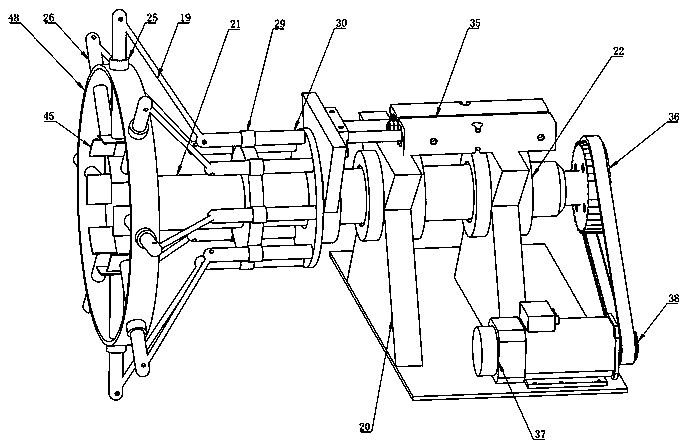

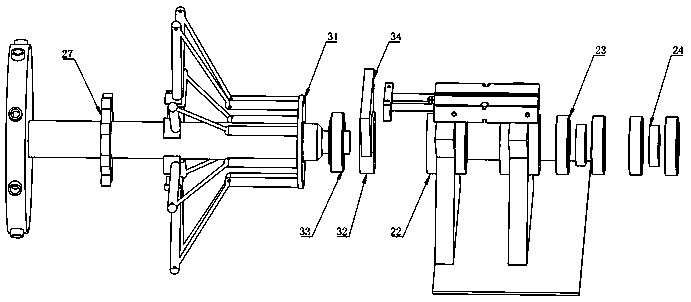

[0019] Specific implementation method: combined Figure 1-6As shown, it includes frame 1, holding device 2, feeding device 3, supporting device 4 and cutting device 5; feeding device 3 is fixedly connected to the middle position inside frame 1; the bottom of holding device 2 and the top of feeding device 3 are welded; supporting device 4 is welded at the left end inside the frame 1; the cutting device 5 is set on the side of the supporting device 4; the feeding device 3 includes: the first guide rail 6, the coupling 7 and the fixing plate 8; the bottom of the first guide rail 6 is welded at the middle position inside the frame 1 ; The inside of the first guide rail 6 is provided with a first screw mandrel 46; the two ends of the first screw mandrel 46 are connected to the bearings of the first guide rail 6; the right end of the first guide rail 6 is screwed with the first servo motor 9; It is connected with the right end of the first screw rod 46 through the coupling 7; the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com