Preparation method of graphene aluminum matrix composite

A technology of aluminum-based composite materials and graphene, which is applied in the field of nanomaterials, can solve the problems of low production efficiency and achieve the effect of low production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific operation steps are as follows:

[0032] (1) At 10°C, put the prepared 2L graphene oxide aqueous solution (the solid content of graphene oxide is 4g / L) in a glass kettle with a low-temperature oil bath jacket and stir, take 2kg of pure aluminum powder and add graphite oxide In the olefin aqueous solution, under the rotating speed of 150r / min, continue stirring for 3h;

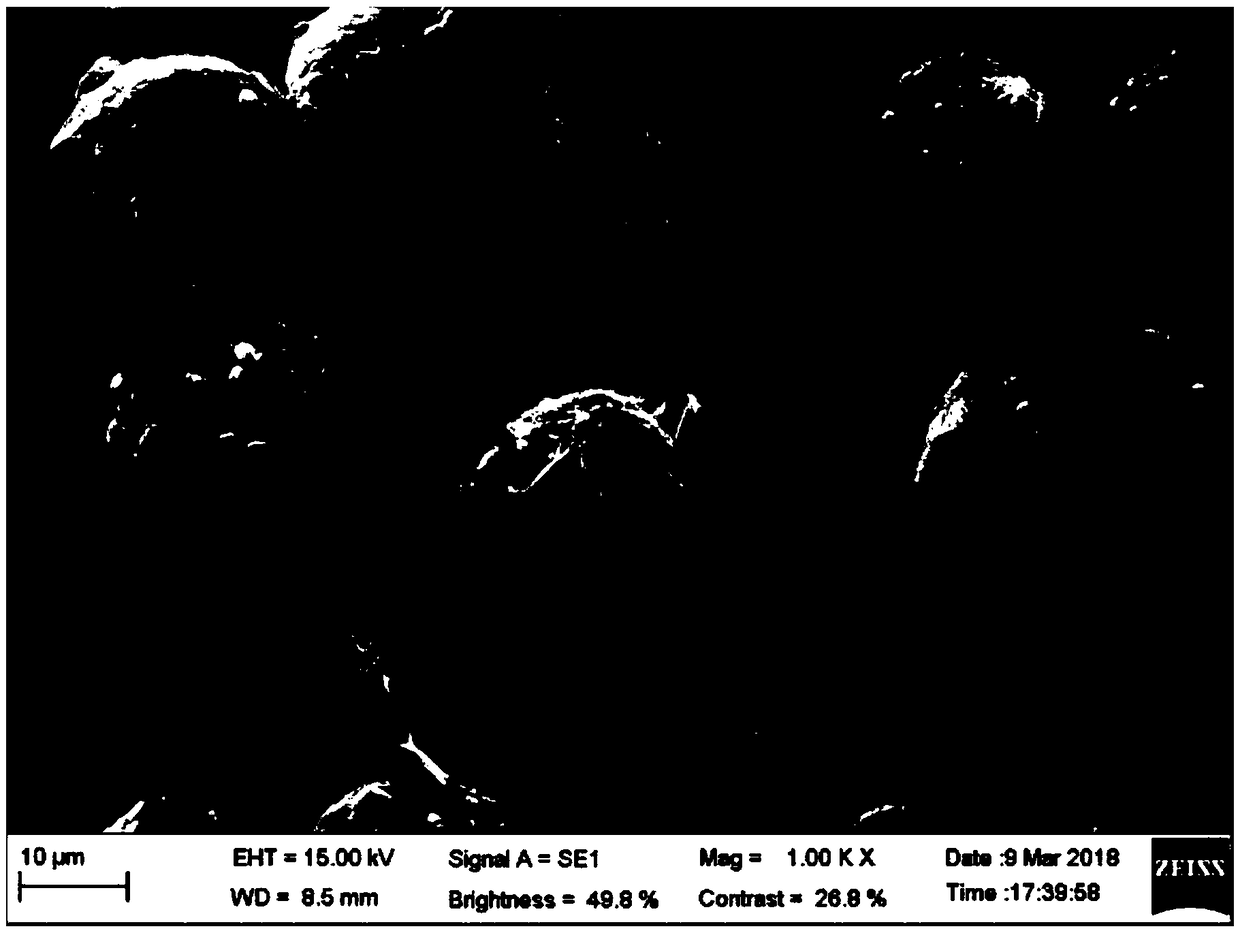

[0033] (2) The graphene aluminum powder slurry mixed and dispersed in step (1) enters the centrifugal spray drying tower through a peristaltic pump under low temperature stirring, the feeding speed is 45rpm, the inlet air temperature is 150°C, and the outlet air temperature is 100°C , the atomizing nozzle rotating speed is 22000r / min, obtains graphene-aluminum matrix composite powder, and this graphene-aluminum matrix composite material is made up of metal particle and graphene, and described metal particle is evenly coated by graphene (such as figure 1 shown).

[0034] The preparation met...

Embodiment 2

[0036] The specific operation steps are as follows:

[0037] (1) At 3°C, put the prepared 5L graphene oxide aqueous solution (the solid content of graphene oxide is 2g / L) in a glass kettle with a low-temperature oil bath jacket and stir, take 3kg of pure aluminum powder and add graphite oxide In the olefin aqueous solution, under the rotating speed of 200r / min, continue stirring for 5h;

[0038] (2) The graphene aluminum powder slurry mixed and dispersed in step (1) enters the centrifugal spray drying tower through a peristaltic pump under low temperature stirring, the feeding speed is 50rpm, the inlet air temperature is 180°C, and the outlet air temperature is 110°C , the rotation speed of the atomizing nozzle is 24000r / min, and the graphene-aluminum matrix composite powder is obtained. The graphene-aluminum matrix composite material is composed of metal particles and graphene, and the metal particles are uniformly coated by graphene.

[0039] The preparation method of a gra...

Embodiment 3

[0041] The specific operation steps are as follows:

[0042](1) At 2°C, put the prepared 2L graphene oxide aqueous solution (the solid content of graphene oxide is 5g / L) in a glass kettle with a low-temperature oil bath jacket and stir, take 2kg of pure aluminum powder and add graphite oxide In the olefin aqueous solution, under the rotating speed of 150r / min, continue stirring for 8h;

[0043] (2) The graphene aluminum powder slurry mixed and dispersed in step (1) enters the centrifugal spray drying tower through a peristaltic pump under low temperature stirring, the feeding speed is 60rpm, the inlet air temperature is 120°C, and the outlet air temperature is 110°C , the rotation speed of the atomizing nozzle is 20000r / min, and the graphene-aluminum-based composite powder is obtained. The graphene-aluminum-based composite material is composed of metal particles and graphene, and the metal particles are uniformly coated by graphene.

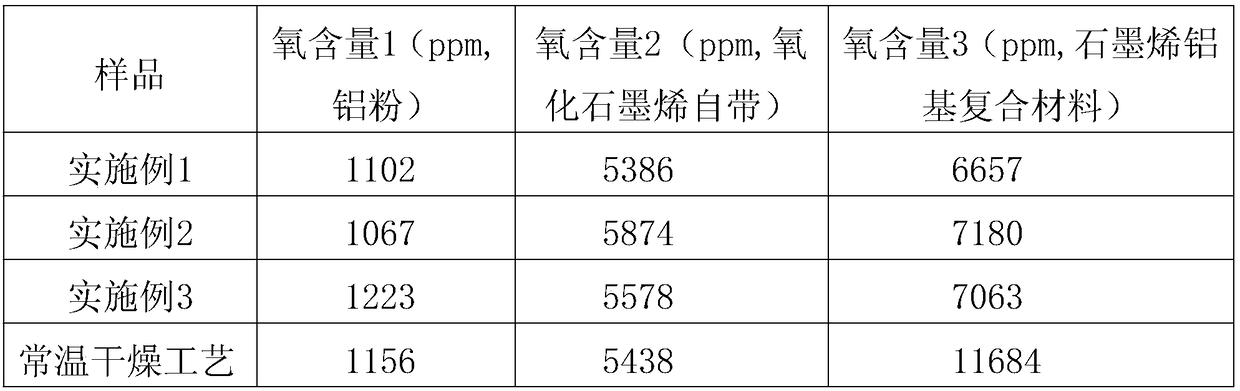

[0044] The raw material of embodiment 1-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com