Process model structure of casting system for caliper body casting and use method

A casting system and model structure technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problem of hazards to driver safety, difficulty in feeding, and inability to reduce sand inclusion and slag inclusion defects and shrinkage defects. and other problems, to achieve the effect of smooth pouring process, increase thermal modulus, and reduce bad sand and slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

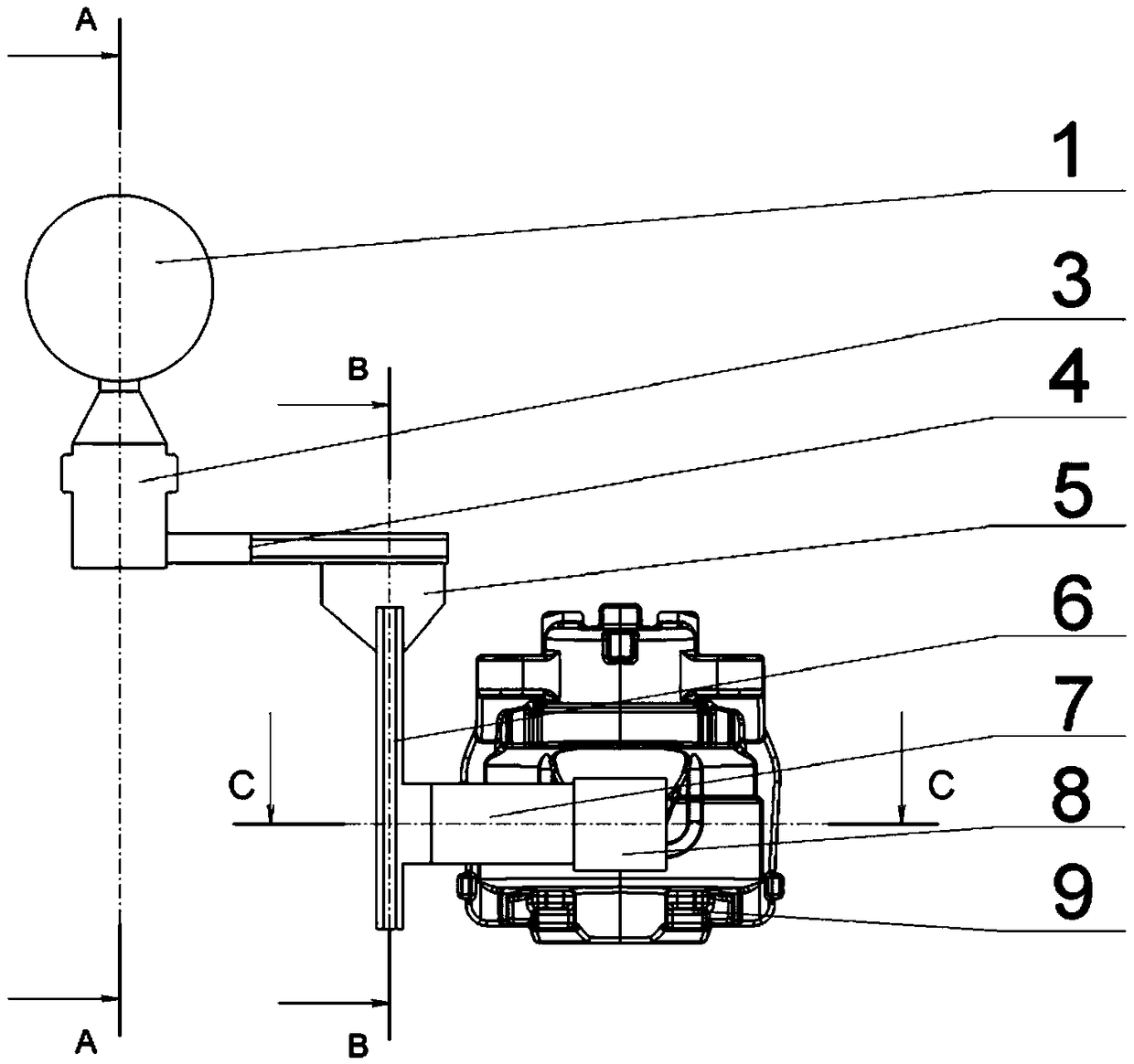

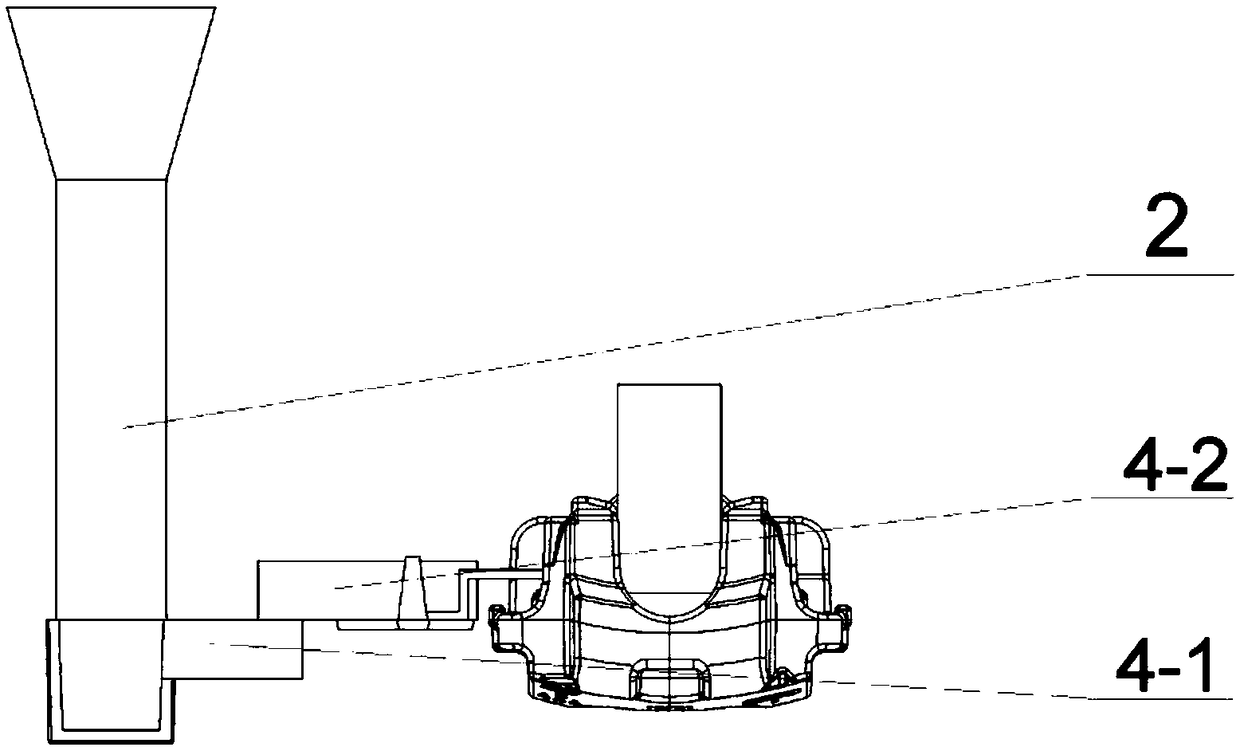

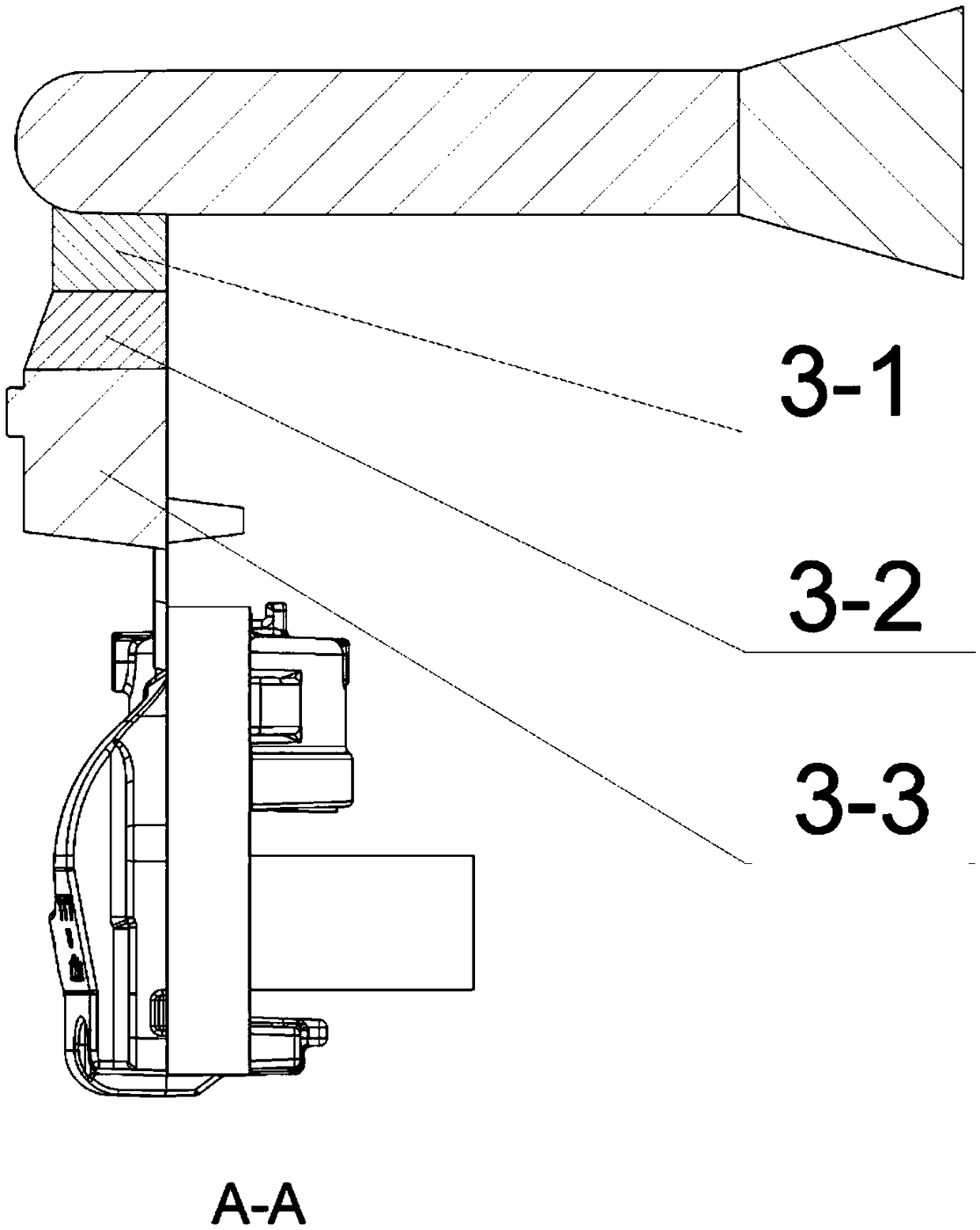

[0047] Embodiment 1: a kind of model structure (see Figure 1-Figure 6 ), which is characterized in that it includes a pouring cup 1, a vertical runner 2, a main runner 3, a runner 4, a cut-off plate 5, a runner 6, a water inlet channel 7, a riser 8 and A pliers mold 9; the output end of the pouring cup 1 is connected to the input end of the vertical sprue 2, the output end of the vertical sprue 2 is connected to the input end of the main sprue 3, and the output end of the main sprue 3 Connect the input end of the runner 4, the output end of the runner 4 is connected to the input end of the cut-off piece 5, the output end of the cut-off piece 5 is connected to the input end of the sub-runner 6, and the output end of the sub-runner 6 The output end is connected to the input end of the water inlet channel 7, the output end of the water inlet channel 7 is connected to the input end of the riser 8, and the output end of the riser 8 is connected to the clamp body mold 9; the riser ...

Embodiment 2

[0064] The caliper body is the key safety performance component of the automobile brake system. The shape and structure of the caliper body are determined by the vehicle model and the overall design of the internal structure. The structure of each caliper body is different, so the shape and structure of each caliper body mold are also different.

[0065] Example 1 is a set of basic units of the process model structure of the casting system for clamp body casting. In the actual production process, depending on the size of the production line and the size of the matching template, 1-20 clamp body molds can be scheduled for production. The specific process model structures are all derived from Example 1.

[0066] In the process of evolving from a single clamp mold to multiple clamp molds, the number of pouring cups and vertical runners remains unchanged, of which the main runner, runner, interceptor, runner, water inlet channel, riser The number increases with the increase of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com