Preparation method and application of water-stable triazinyl metal organic frame material

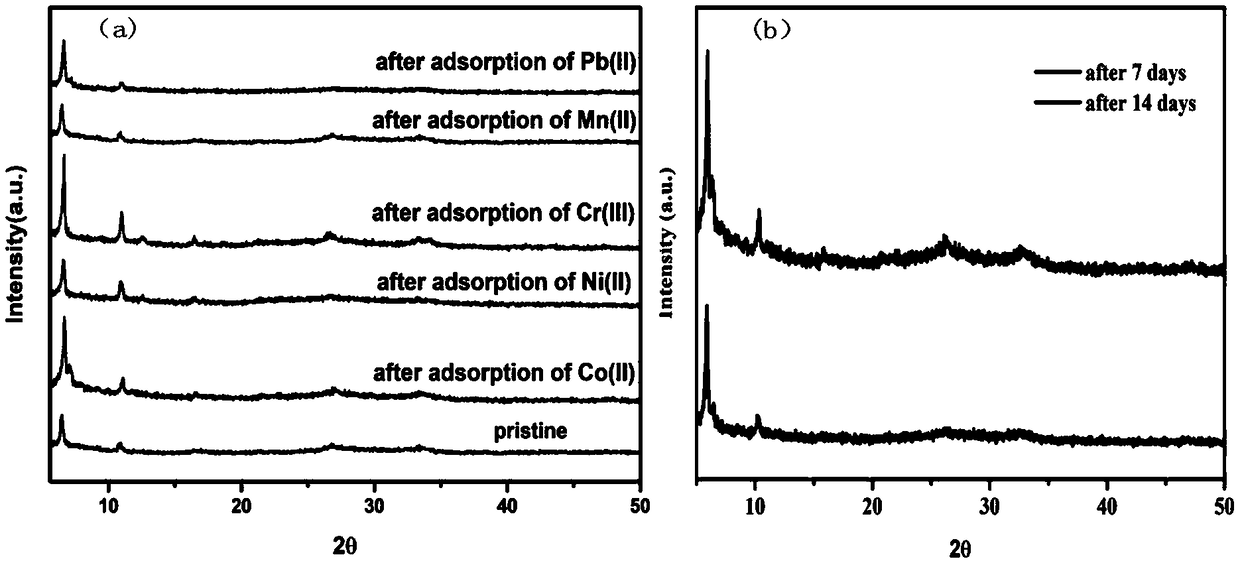

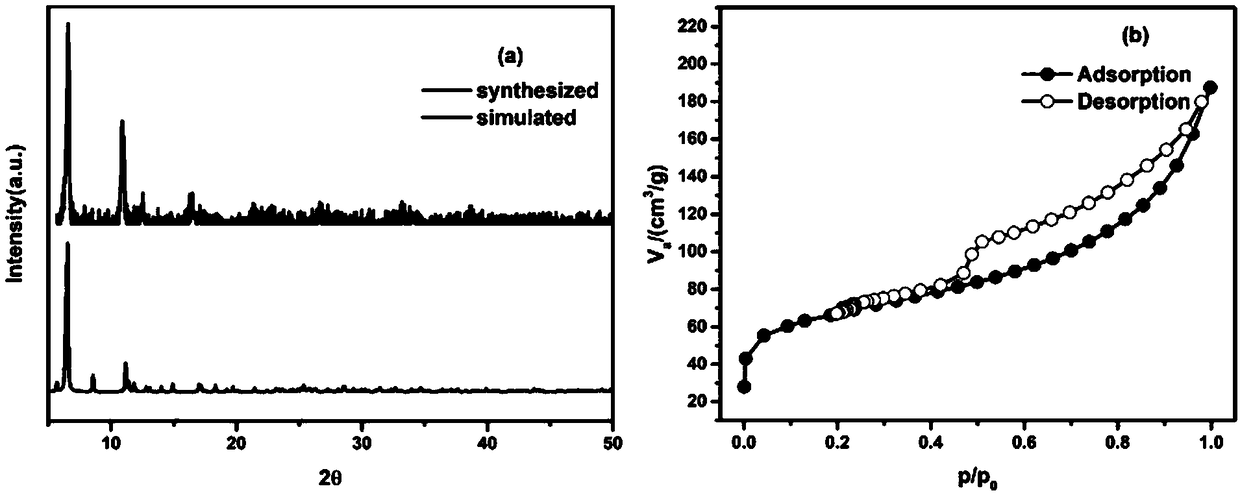

An organic framework and metal-based technology, applied in the field of preparation of water-stable triazine-based metal-organic framework materials, can solve the problems of complex steps, acid and alkali resistance, poor water stability, etc., and achieve simple preparation method, easy operation, good The effect of water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a water-stable triazine-based metal-organic framework material, comprising the steps of:

[0040] (1) Dissolve 136 μmol of 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine in a mixed solution of 6 mL DMF and 6 mL methanol;

[0041] (2) Continue to add 118.4 μmol of bismuth nitrate, stir fully for 30 minutes, then transfer to the polytetrafluoroethylene reactor; put the reactor into a 130°C oven and keep it warm for 44h to carry out the solvothermal reaction. At room temperature, vacuum filter, wash with DMF and methanol, and dry at 60°C for 12 hours to obtain a white powder that is CAU-7-TATB.

Embodiment 2

[0043] A method for preparing a water-stable triazine-based metal-organic framework material, comprising the steps of:

[0044] (1) Dissolve 136 μmol 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine in a mixed solution of 6 mL DMF and 9 mL methanol;

[0045](2) Continue to add 136 μmol of bismuth chloride, fully stir for 30 minutes, then transfer to the polytetrafluoroethylene reactor; put the reactor into a 150°C oven and keep warm for 40h to carry out the solvothermal reaction, after the reaction is completed, it will naturally drop to At room temperature, vacuum filter, wash with DMF and methanol, and dry at 50°C for 14 hours to obtain a white powder that is CAU-7-TATB.

Embodiment 3

[0047] A method for preparing a water-stable triazine-based metal-organic framework material, comprising the steps of:

[0048] (1) Dissolve 136 μmol of trimercapto-s-triazine in 6 mL of DMF and 7 mL of methanol mixed solution;

[0049] (2) Continue to add 90.6 μmol of bismuth oxide, stir fully for 30 minutes, and then transfer to the polytetrafluoroethylene reactor; put the reactor into a 140°C oven and keep it warm for 48 hours to carry out the solvothermal reaction. After the reaction is completed, it will naturally drop to Vacuum filter at room temperature, wash with DMF and methanol, and dry at 80°C for 10 hours to obtain a white powder that is CAU-7-TATB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com