Method for processing seabuckthorn juice

A technology of seabuckthorn fruit juice and processing method, which is applied to the functions of food ingredients, food science, application, etc., can solve the problems of lack of leading role, the development potential of seabuckthorn is not fully tapped, etc., and achieve low cost, long storage time, and high nutritional value. rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

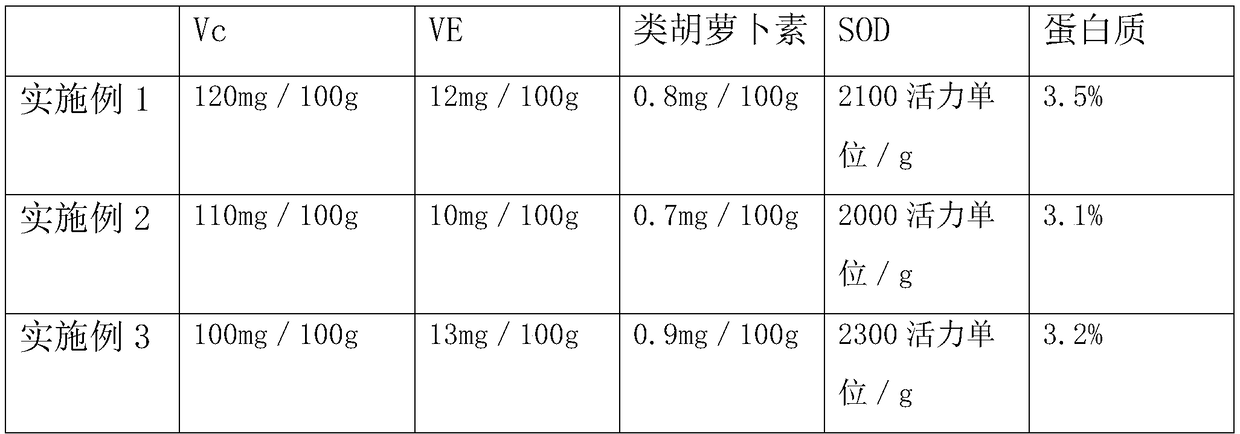

Examples

preparation example Construction

[0018] (1) The preparation of seabuckthorn puree, select 8-9 minutes mature seabuckthorn fruits, remove moldy and deteriorated fruits and impurities, wash and disinfect with potassium permanganate solution, rinse with water, drain and use a double roll crusher Crushing requires uniform particle size and a crushing degree of 3 to 4 mm. The crushed pulp is sent to a wrapped juicer. After the first juicing, add 15% water to the dregs, mix well and then squeeze the second time. The juice is twice Mix and measure the acidity of 1.5%. If the acidity is too high, dilute it with drinking water. Heat the squeezed seabuckthorn juice to a colloidal coagulation temperature of 77-78°C and treat it for 1-3 minutes to coagulate the colloidal substances in the juice. Filter by plate and frame Remove the slag by machine filtration, and the filtrate is sterilized at a high temperature for 15 to 30 seconds at a temperature of 93°C to obtain sea buckthorn puree;

[0019] (2) Preparation of seabuc...

Embodiment 1

[0022] A processing method of seabuckthorn fruit juice, which comprises the following steps:

[0023] (1) The preparation of seabuckthorn puree, select 80% mature seabuckthorn fruits, remove moldy and deteriorated fruits and impurities, disinfect with potassium permanganate solution after washing, rinse with clear water, and crush with double roll crusher after draining, It is required that the particle size is uniform and the crushing degree is 3 mm. The crushed pulp is sent to the wrapped juice extractor. After the first juice is squeezed, add 15% water to the dregs, stir well and then squeeze the second time. The two juices are mixed and measured. The acidity is 1.5%. If the acidity is too high, dilute it with drinking water. Heat the squeezed seabuckthorn juice to the colloidal coagulation temperature of 77.3°C for 2 minutes to coagulate the colloidal substances in the juice. Instantaneous sterilization at a temperature of 93°C for 18 seconds to obtain seabuckthorn puree; ...

Embodiment 2

[0027] A processing method of seabuckthorn fruit juice, which comprises the following steps:

[0028] (1) The preparation of seabuckthorn puree, select 90% mature seabuckthorn fruits, remove moldy and deteriorated fruits and impurities, wash and disinfect with potassium permanganate solution, rinse with water, drain and crush with a double roll crusher, It is required that the particle size is uniform and the degree of crushing is 4 mm. The crushed pulp is sent to the wrapped juice extractor. After the first juice is squeezed, 15% water is added to the dregs, and the second time is squeezed after stirring evenly. The two juices are mixed and measured. The acidity is 1.5%. If the acidity is too high, dilute it with drinking water. Heat the squeezed seabuckthorn juice to the colloidal coagulation temperature of 77.8°C for 2 minutes to coagulate the colloidal substances in the juice. Instantaneous sterilization at a temperature of 93°C for 19 seconds to obtain seabuckthorn puree;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com