Sunflower seed threshing device

A threshing device and a technology for melon seeds, which are applied in the agricultural field, can solve the problems of difficult stacking, high cost of manual peeling, and difficulty in balancing the cleanliness of sunflower seeds, and achieve the effect of reducing the occupied space and facilitating disposal or reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

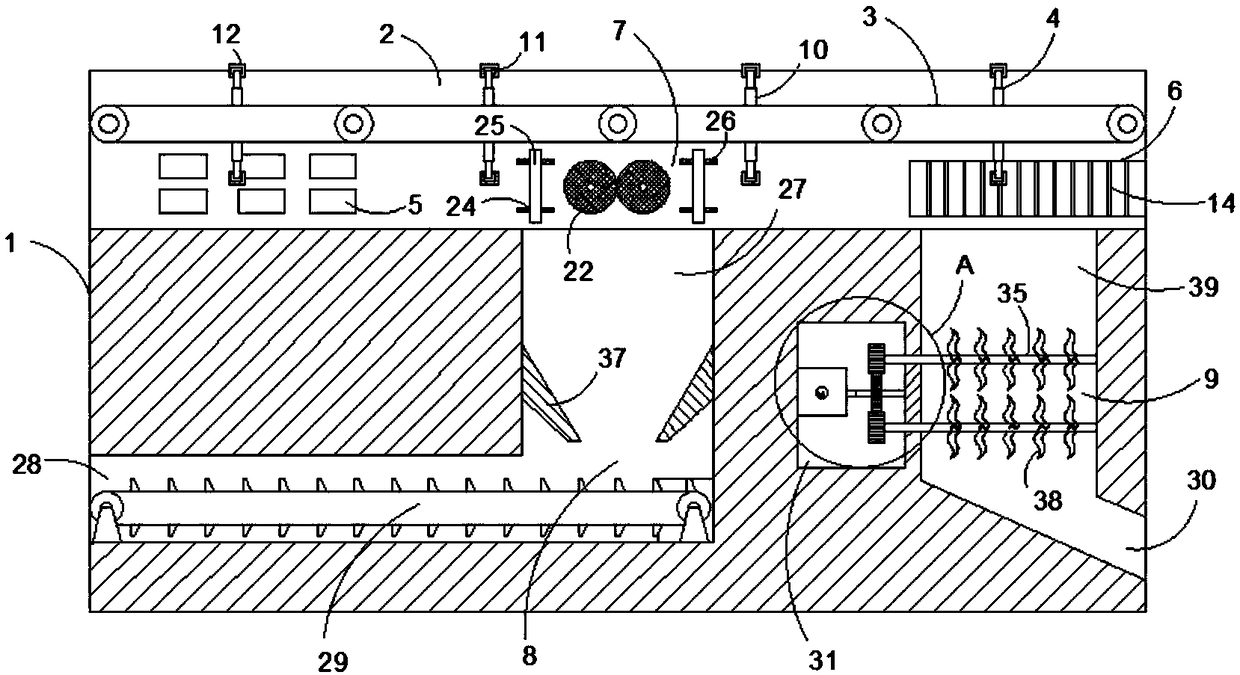

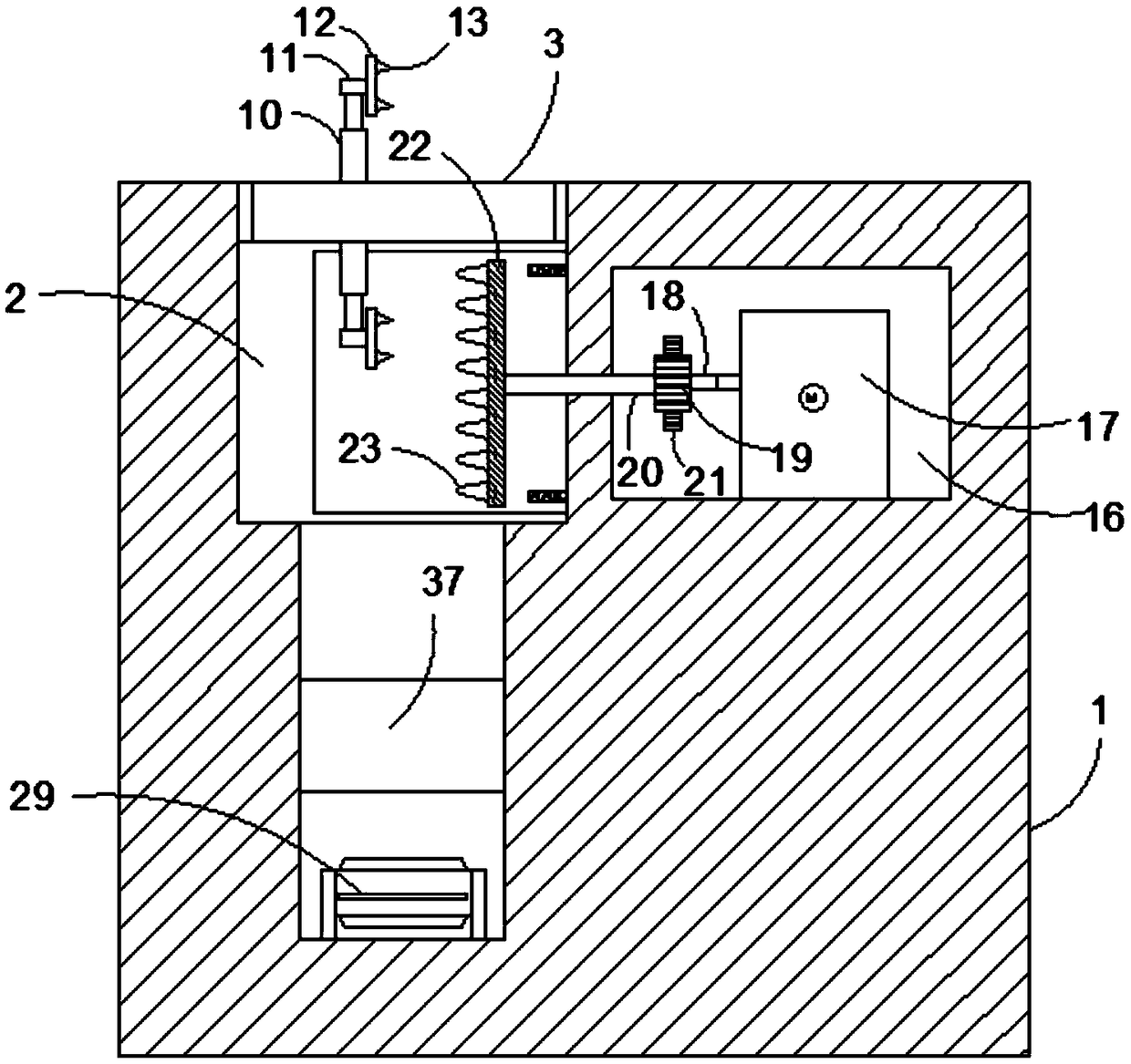

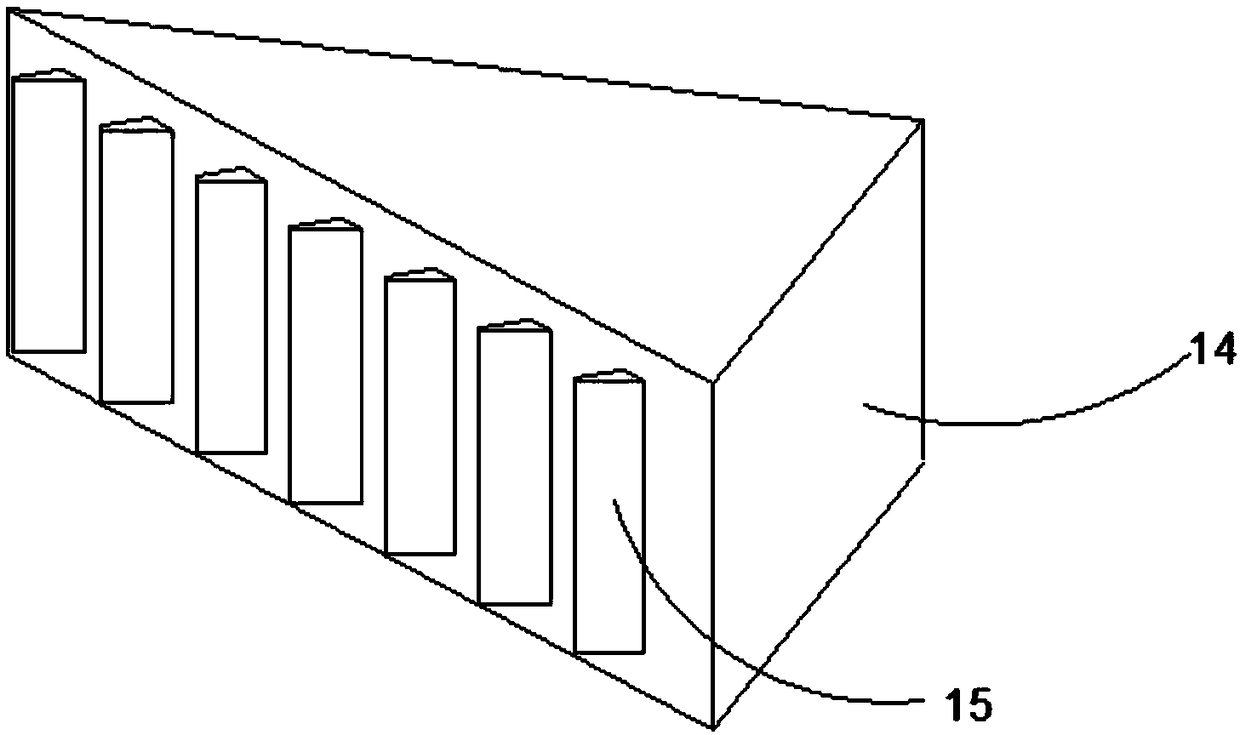

[0024] Such as Figure 1-4 As shown, a melon seed threshing device comprises a body 1, the upper end of the body 1 is provided with a through groove 2 that runs through left and right, the first conveyor belt 3 is arranged in the through groove 2, and the front and rear ends of the first conveyor belt 3 are connected with the through groove respectively. The inner walls of the front and rear ends of 2 are fixedly connected, the first conveyor belt 3 is fixedly connected with a plurality of clamping parts 4, and the clamping parts 4 include telescopic rods 10 fixedly connected to the first conveyor belt 3, and the telescopic rods 10 are used to adjust the length to To match sunflower discs of different sizes, the end of the telescopic rod 10 away from the first conveyor belt 3 is fixedly connected with a connecting block 11 , and one end side wall of the connecting block 11 is fixedly connected with a connecting plate 12 , and the connecting plate 12 is far away from the end sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com