A cleaning device for a compaction apparatus

A technology for cleaning devices and equipment, which can be used in drafting equipment, textiles and papermaking, spinning machines, etc., and can solve problems such as adverse effects on the compaction quality of fiber materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

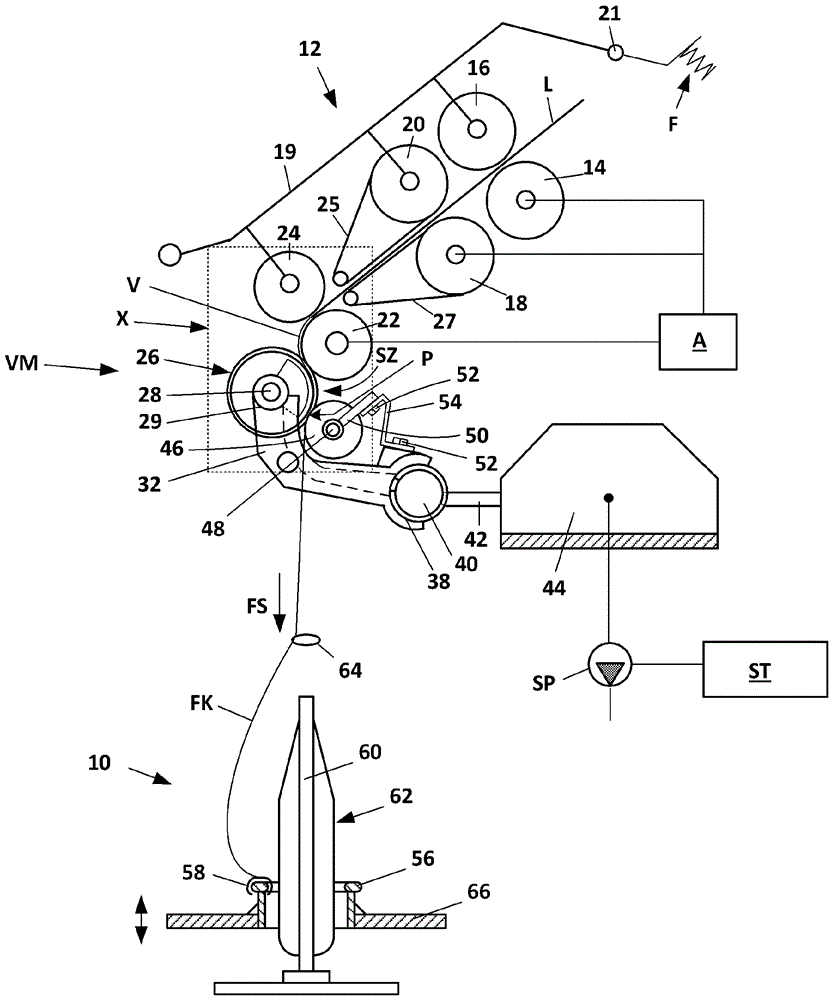

[0021] figure 1 Shown is a schematic side view of a spinneret 10 of a spinning machine (ring spinning machine) having a drawing frame unit 12 provided with a pair of feed rollers 14, 16. Center roller pairs 18, 20 and output roller pairs 22, 24. The bottom roller pairs 14, 18, 22 are connected to a drive A, which is schematically shown in the figures. The upper roller pair 16 , 20 , 24 is designed as a pressure roller and is mounted such that it can be moved rotationally on a pivotally mounted pressure arm 19 . The pressure arm 19 is mounted to pivot about a lever shaft 21 and is acted upon by a spring element F. As shown in FIG. The pressure rollers 16 , 20 , 24 and / or the belt 27 are driven by friction via the belt 25 running on the driven bottom rollers 14 , 18 , 22 . The peripheral speed of the driven roller 18 is slightly greater than the peripheral speed of the driven roller 14 .

[0022] The fiber material fed to the drawing frame unit 12 is subjected to predrawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com