multi-frequency antenna device

A multi-frequency antenna and resonant frequency technology, applied in the field of multi-frequency antenna devices, can solve the problems of reducing the resonant frequency of the microstrip antenna 10, increasing the manufacturing cost of the microstrip antenna 10, and being difficult to adjust accurately and effectively at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

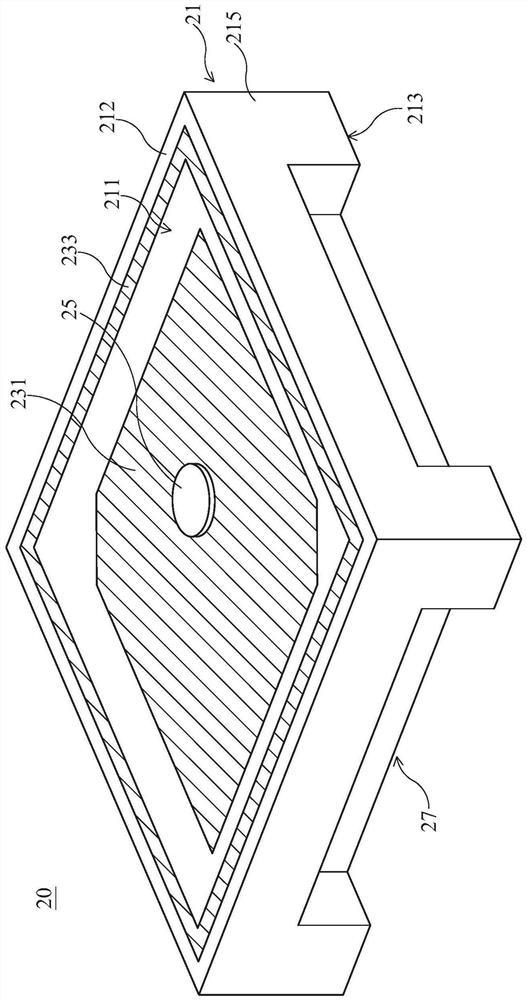

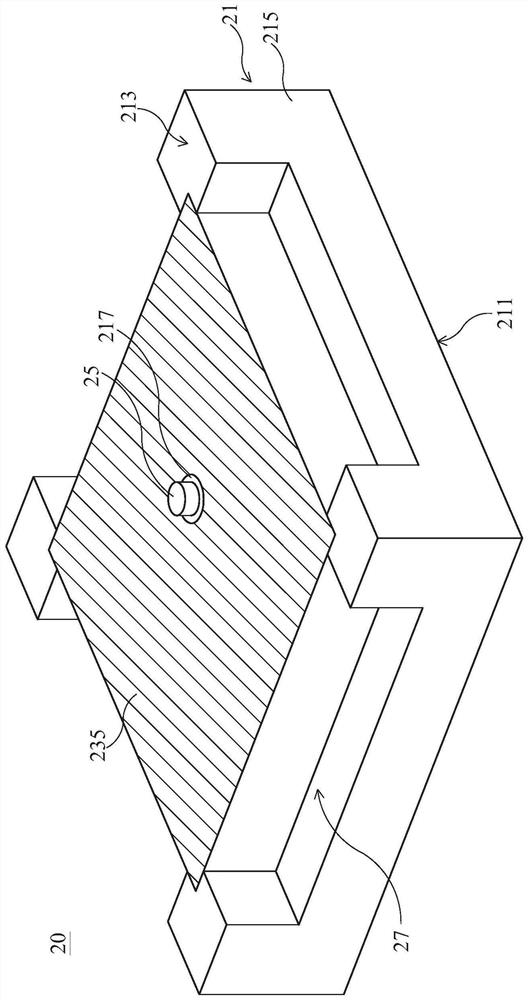

[0092] see figure 2 and image 3 , are respectively the top and bottom perspective schematic diagrams of an embodiment of the multi-frequency antenna device of the present invention. As shown in the figure, the multi-frequency antenna device 20 mainly includes an insulating base 21, at least one first electrode layer 231, at least one second electrode layer 233, at least one third electrode layer 235, at least one conductive element 25 and at least one concave Slot 27.

[0093] The insulating base 21 includes a first surface 211, a second surface 213, at least one side surface 215 and at least one first through hole 217, wherein the first surface 211 and the second surface 213 are two opposing sides across the insulating base 21. The surfaces, for example the first surface 211 is the top surface and the second surface 213 is the bottom surface. In addition, the first surface 211 is connected to the second surface 213 via the side surface 215 , for example, the insulating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com