Self-mending fuse of liquid metal structure

A liquid metal and fuse technology, applied in electrical components, circuits, emergency protection devices, etc., can solve the problems of uncertain specification selection, poor safety, and high cost, saving replacement costs, improving maintenance efficiency, and solving the inconvenience of replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

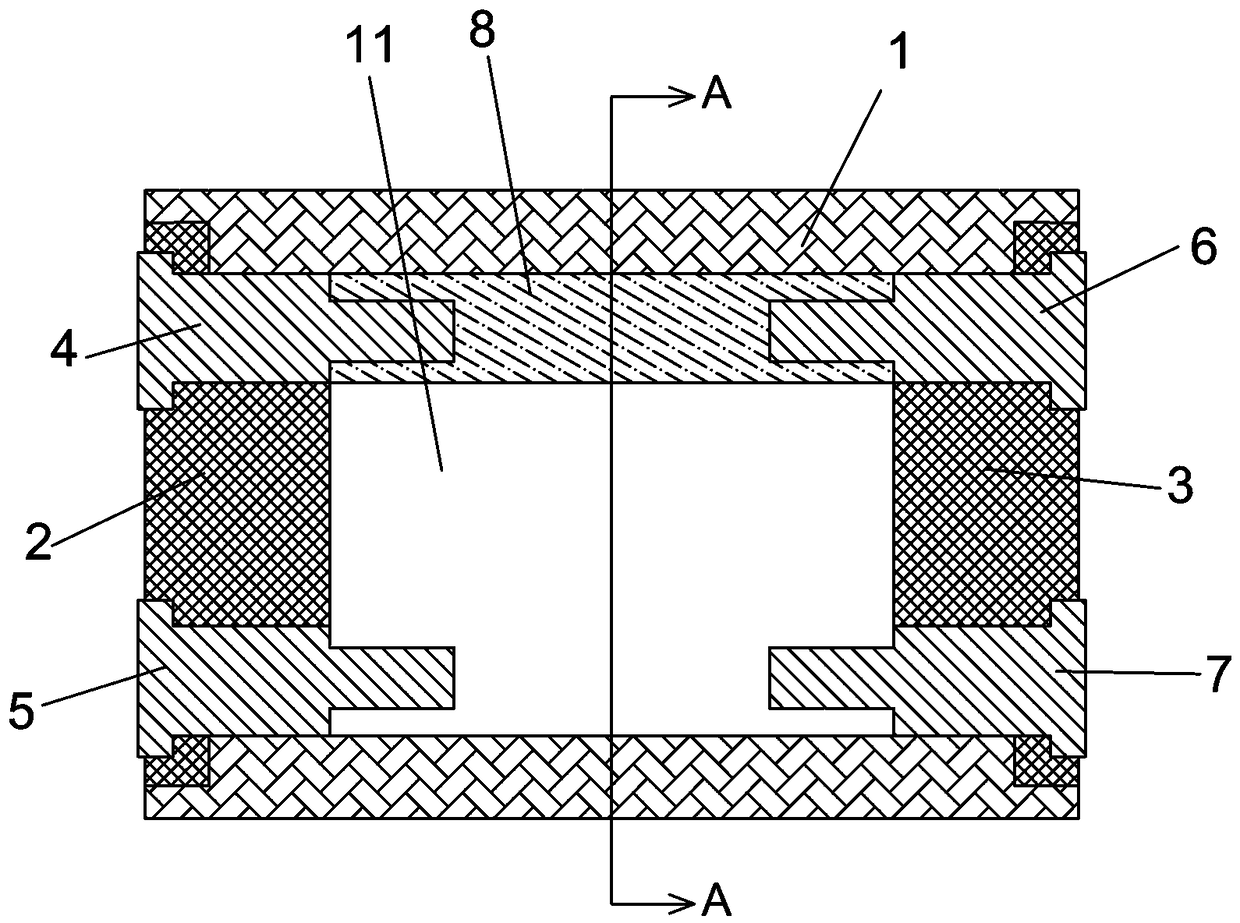

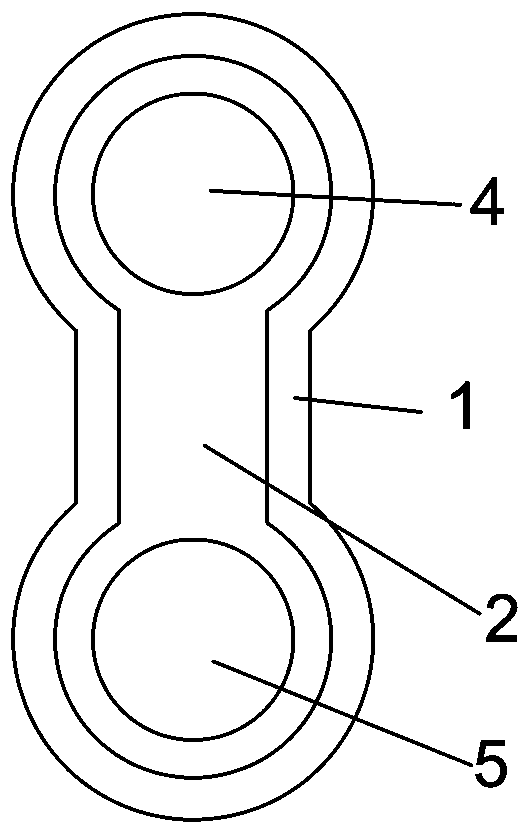

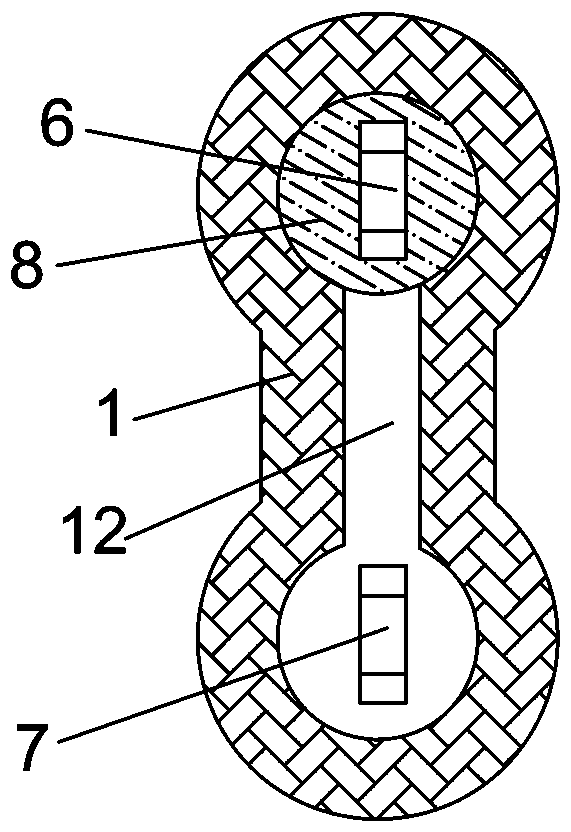

[0020] The structure of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

[0021] refer to Figure 1 to Figure 3 As shown in , the liquid metal structure self-resetting fuse of the present invention includes a porcelain tube 1, and the two ends of the porcelain tube 1 are respectively provided with a first electrode fixing seat 2 and a second electrode fixing seat 3, and the first electrode fixing seat 2 The first electrode 4 and the second electrode 5 inserted into the porcelain tube cavity 11 are arranged near the top and the bottom respectively; The three electrodes 6 and the fourth electrode 7 ; the cavity 11 of the ceramic tube is provided with a liquid metal conductor 8 which is solid under normal conditions and electrically connects the first electrode 4 and the third electrode 6 .

[0022] That is to say, the liquid metal conductor 8 is connected in series b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com